What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

10 min read

Stefan Badertscher

:

December 7, 2020

Stefan Badertscher

:

December 7, 2020

![What Folder-Gluer Packer Is Right For You? [+VIDEO]](https://impack.ca/hubfs/X21-004.png)

If you're thinking of getting a packing aid, semi-automating your packing or thrusting into full-automation, then you might be asking yourself: What folder-gluer packer is right for my production?

You can probably agree with me that having many options is great, but — just like shopping for a car — having to choose from all those options can be overwhelming and annoyingly time-consuming.

I hear you.

Hey! Hani Hallal here from Impack packaging!

Quick question: Do you fall under one of those 3 categories?

No matter which of the 3 questions answered “yes” to, you are all here because you have one critical goal in common: You want to know how to increase the output capacity of your folder-gluer, but you hit a brick wall. BANG!

This ARTICLE + VIDEO are going to outline to you, step-by-step, what packer is right for you.

Of all the packers on the market, which one is best for what production?

Collecting Tables, Semi-Auto packers and Fully-Auto packers are all viable options to maximizing your folder-gluer’s productivity, but each has distinct advantages, disadvantages and characteristics that many companies shy away from explaining.

As manufacturers and installers of Manual, Semi-Auto, Auto and Fully-Auto folder-gluer packers, we’ve helped hundreds of business owners push their folder-gluer to its maximum capacity.

And, we believe it is important to give an honest comparison between the different kinds of packers on the market. So, to help you make a more informed decision, we’ll share with you everything you need to know about the different types of folder-gluer packers on the market.

What’s the difference between Collecting Tables, Semi-Auto Packers and Fully-Auto Packers?

Here’s the truth — whether automated fully, partially, or not at all — no machine on the market is immune to problems; however, getting the right equipment for the right products will help you save a ton of money...and your sanity!

When it comes to comparing Collecting Tables Vs. Semi-Auto packers Vs. Fully-Auto packers, fully-auto packers are easily the more tempting option that customers want.

However, it is also the more complex option requiring digital knowledge, a larger footprint, more money, and much stricter emergency shutdown protocols. That being said, for some companies, full-automation is the only realistic option.

So, how do you choose?

Let us take a deeper look into the good, the bad, and the ugly of each.

There is no doubt that Collecting Tables are the quickest and easiest to set up because the setup time is virtually zero. Semi-auto packers also have very short setup times. That said, you still have to adjust the case height, case ejection, case taping unit, configure the box turner, etc.

The setup time between semi-auto packers and fully-auto packers is unmatched. Taking that into account, semi-auto packers still require more setup than Collecting Tables that require nearly no setup.

The main disadvantage of Collecting Tables is that your packing person(s) still has to lift everything. There is absolutely no way where they can avoid lifting the boxes. And that is because there is no case management included. In the end, your packing person(s) needs to lift the batches of boxes in the air and place them into the case.

Because they can only lift so much with their own hands, they would be lifting small, limited batches of 3-5 tons per shift. With the repetitive overuse of their hands for spin rotation, and their shoulders for specific movements, they become subject to Repetitive Strain Injury (RSI).

In some cases, the packing person(s) may become skilled at grabbing a full row of boxes at once and placing it into the case, but we rarely see it happening.

Given that Collecting Tables involve no automation and no case management, your packing personnel need to do the lifting, ejecting and packing fully manually. This means that you can physically move fewer boxes thereby limiting your capabilities and inevitably making you much slower.

Moving from no-automation to semi-automation brings along many benefits. One of the major advantages is that semi-automatic packers are quicker and easier to install & set up relative to fully-automatic packers.

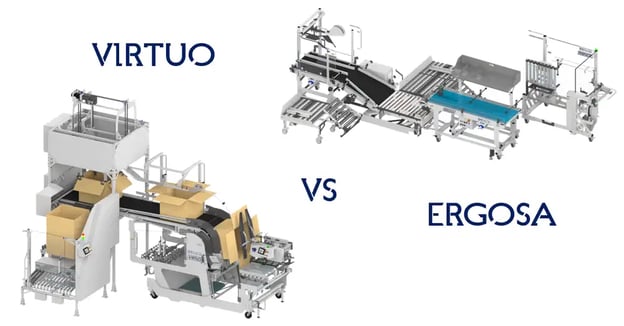

Because there are several packers on the market, I will use our semi-automatic packer, the “Ergosa,” shown below, as an example.

The ERGOSA Universal Packing Solution is a modular system that can be configured to optimize the packing of specific box types. In 3-7 minutes ,a member of your packing team can change between packing modes depending on the type of box you are running.

Visit the Ergosa product page to see how easy it is to switch between modes.

Quick fact: Ergosa is an abbreviation for Ergo-nomic, Semi-Automatic.

When it comes to semi-auto packers, our Ergosa packer is a universal folder-gluer packer that combines the flexibility of a semi-automatic packer with the performance of an automatic one.

The Ergosa is the first step towards semi-automation from the traditional hand-packing process used with Collecting Tables and its setup time is as short as 5 minutes. Being economical, simple and highly versatile, the Ergosa can help double your packing speed with only 1 packing person (instead of 2 packing people) thus making the packing speed per person more than 4 times faster.

Perhaps one of the biggest selling points for a semi-auto packer is its level of flexibility. By installing a semi-auto packer on your folder-gluer, you give your personnel the power of easy access.

Going back to the example of our Ergosa, easy access to the boxes allows your personnel to make adjustments, quality control checks and corrections without ever needing to interrupt the production. In direct contrast to Collecting Tables, the Ergosa includes case management.

Because of its high level of flexibility and easy access, an Ergosa can run quite-literally anything you produce on your folder-gluer.

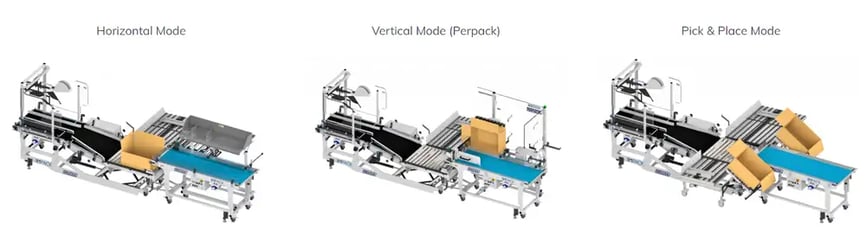

In addition, you can configure the Ergosa according to your needs. The Ergosa has 3 main packing modes: The “Horizontal Mode,” the “Vertical Mode” and the “Pick & Place (or Manual) Mode.”

With those 3 modes, you can run anything from small to medium boxes, straight lines, 4/6 corners, carton and corrugated boards and multi-format boxes.

What about Crash-lock/auto-bottom boxes? No problem! The Ergosa can run it in Pick & Place Mode or using the MFA Batch Inverting Module (Ergosa C in Vertical Mode) if you have large production runs (40-50 Million per year).

The best part? It is compatible with all folder-gluer models regardless of its type.

If you want to learn more about the Ergosa’s 3 main packing modes, we dedicated a full article that breaks down the 3 main packing modes of the Ergosa, the benefits each mode can offer and which mode is best for what production!

Let’s move on to the disadvantages.

No machine is perfect; that’s just the reality. In some specific scenarios, semi-automation is just not the best choice.

Yes, ease-of-access and the ability to perform quality-control checks are great — if that’s something you need. However, with the power of access and the ability to make adjustments, comes the drawback of slower speed.

Another important point to consider is that you still need human supervision. If you operate in an area where there are labor shortages or rising wages, then this option may not be worth the payback.

With the demand soaring for unconventional boxes that come in all weird sizes, shapes and their own inconveniences, adapting to the complex needs of the market has become more important than ever.

Depending on the types of boxes you produce and what ways you implement to maximize the capacity of your folder-gluer, productivity can vary drastically.

“Why can’t I pack this faster?!”

That sentence above constitutes 95% of the questions we get from our customers here at IMPACK.

It is not a question of how reliable the folder-gluer packer is but rather a question of how you use it.

Because a semi-auto packer is highly versatile and flexible, there are so many things you can do to push your folder-gluer to its maximum capacity. That said, there are so many ways where you could be losing productivity and causing bottlenecks to your own folding-gluing lines. This is why making the most out of your semi-auto packer training is so important.

Semi-automatic packers are far more versatile and flexible than fully-automatic packers and there is absolutely no doubt that they are more flexible and adaptable when compared to fully-auto packers but it is important for you to factor in the reality of your own company.

Fully-auto packers can be a perfect fit if extreme productivity is required, either because your demand is quickly increasing or because you are short of personnel.

Taking that into account, it is just as important to not overestimate your needs and end up with a packer that is too complex, too expensive and completely not tailored to you, for you.

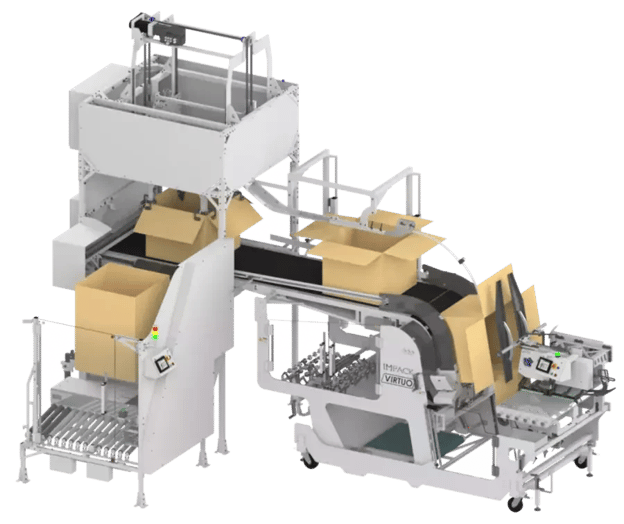

A big advantage that fully-auto packers offer is high production speed. Let’s take our fully-auto packer “Virtuo + ACF” as an example to make things easier. Here is a snapshot of the “Virtuo + ACF:”

The Virtuo + ACF combination is the only 100% fully automatic folder-gluer packer that exists on the market for both corrugated and carton boards. It is the most compact and economical auto-packer in 2021.

If your typical production is one-row, one-layer — medium to large boxes — with an extreme focus on speed, then full-automation with the Virtuo + ACF might be the perfect fit.

The Virtuo + ACF has a speed of up to 8 cases per minute, with a high-precision laser counter, and on a small footprint.

However, if your typical production is multi-row, multi-layer case packing, then the Virtuo + ACF is not the right fit for you.

Fully-auto packers take no breaks and no vacations. Operating 24/7, the capabilities of those machines are unparalleled.

If you’re running large volumes (100,000-150,000 boxes/setup of folding cartons or 40,000 – 60,000 boxes/setup of laminated boards) with standardized boxes, then constant productivity is critical for your company.

In such situations where there is a requirement for consistency and speed, fully-auto packers are the only viable option.

Fully-automatic packers involve a very precise installation process that requires much more preparation, technical knowledge and complexity than semi-automatic packers. Expectedly, it is more expensive, as a one-time cost, and more limited in terms of what you can do.

This is where the concept of “limitation” comes into play. With a semi-auto packer such as the Ergosa, you can shoot whatever box you want through your folder-gluer as you have the power of easy access and the flexibility to take out any box you want with your own hands at any time and place it into the case.

On the other hand, when it comes to a fully-auto packer like the Virtuo + ACF you need a larger footprint. Your fully automatic packer has to be 100% safe. Hence, if there is ever a problem, you have to shut it down to zero with an emergency stop, otherwise it is too dangerous for a human.

If you’re looking to produce crash-lock/auto-bottom boxes like a Happy Meal, then you’re happy-go-lucky with a fully-auto packer. However, if you produce other types of boxes, then you need to put your fully-auto monster away as it is dedicated to doing that specific task and is not forgiving enough to be flexible.

On the other hand, with an Ergosa packer in Vertical Mode, you can run at relatively high speeds with crash-lock/auto-bottom boxes and only 1 human supervisor is needed. If they see that the box is not perfect, they can easily take it out and maintain the same speed, or alternatively, they can lower the speed to control everything and then pick up the speed.

You never have to go down to zero with a semi-auto packer.

A Collecting Table, Semi-Auto Packer or a Fully-Auto Packer?

There are situations where a Semi-auto packer or a Fully-auto packer is the better choice. It all depends on your individual needs and specific circumstances.

Before you commit to a decision, there are some important things you need to factor into your decision-making process.

Collect data on your box mix and work methods. With some analysis, you can directly pinpoint the untapped potential of your production.

For each folder-gluer you have, calculate what the percentage of the various boxes types you are producing? How many hours are you running each box? How many shifts do you run?

Use this information to optimize your workflow so that you can maximize potential on your investment in a packing solution. For tips on optimizing your workflow before investing check out this article:

5 Ways to Boost Productivity on the Folder-Gluer Finishing Line Without Investing

Begin by identifying which areas you want to become better and faster at because when you do, you establish a direction for yourself.

For example, if you identify your goal is to hunt the big contracts for crash-lock/auto-bottom boxes then you know you need to produce a specific volume at a certain speed and under XYZ circumstances.

Knowing this will allow you to choose the right machine and the configurations required to tackle that goal. Once you know you are going in that direction, and you have established the technology for a fast setup and stable production, you will become the top speed producer in that market.

Being top speed gives you control over your price point and makes you more competitive.

Many of our clients achieve full ROI on the Ergosa Semi-Automatic Packing Solution in less than one year. After achieving ROI they profit from increased capacity.

They were once producing a specific number of boxes in 2 days, but now they produce the same amount of boxes in 1 day.

We hope this article helps you make a more informed decision on investing in a folder-gluer packer.

Now that you have a better idea of what folder-gluer packer could be right for you, the next steps would be to:

Compare the automation level of the 4 different types of folder-gluer packers and find out which is best for your production.

Get in touch with our sales team for a free box production analysis. And maybe we will show you one of our packers LIVE in action.

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

Today’s cardboard packaging market demands more and more personalization with shorter production runs and boxes with shapes as diverse as they are...

![Folder-Gluer Packers: What Level of Automation Is Right for You? [+VIDEO]](https://impack.ca/hubfs/X22-039-1.png)

Are you considering investing in a folder-gluer packer or folder-gluer stacker?