Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?

11 min read

Stefan Badertscher

:

December 4, 2020

Stefan Badertscher

:

December 4, 2020

![What is a Folder-Gluer Packer and Do You Really Need One? [+ VIDEO]](https://impack.ca/hubfs/X21-003-1.png)

It was a Monday night when I sat back staring blankly at my computer screen after a long first day of work at IMPACK where it dawned on me:

What the heck is even a folder-gluer packer?

Hi! My name is Hani and I am new to IMPACK myself. Being new to the industry, I have the same questions you do about those fancy, complex machines that I want answers for.

I then thought...who else would be better to ask than someone who has worked in the field, day-to-day with those packers for a long time.

Stefan Badertscher, Director of Sales and Marketing at IMPACK, has close to a decade’s worth of experience with folder-gluer packaging equipment and peripherals. Backed with years of practical experience as a Mechanical Engineer, and a high level of sophistication in this industry, I was confident that I would be in good hands for answers.

So, I set up a meeting with Stefan and started asking question after question until I finally understood what a folder-gluer packer is and what companies it is best suited for.

So come along with me as we embark on this journey together!

In this ARTICLE + VIDEO, we will be examining what a folder-gluer packer is, who needs a packer and why do you even need one.

See, the answer to this question varies based on who you ask, but even more interestingly, it depends on how long you speak to them.

All of us business people within this monstrously growing industry like to dub our complementary folder-gluer equipment as the coveted: packer.

But the reality is that not every machine around a folder-gluer is a packer and not every packer is a solution for a folder-gluer.

It all depends on your individual needs, specific circumstances, and a set of intertwined factors.

Some define their traditional Collecting Tables as packers.

Many others define their Box Turners as packers.

Most define their Packers as packers.

So, then, what is a packer?

I will break down the true difference by making a very clear distinction.

Definition: A Collecting Table is a traditional hand-packing process using pick and place stations and is otherwise known as “Packing Help” or “Packing Aid.” Collecting Tables are complementary packing solutions or peripheral devices that can be added to a folder-gluer to help facilitate the packing process.

IMPACK's Collecting Table is the "Packing Help Station."

The most basic collecting table we’ve seen involves crowding a bunch of people at the end of the folder-gluer’s compression belt and asking them to pack as fast as they can. Fortunately, we rarely see clients doing this anymore.

In addition, clients would usually have the most basic tables made of wood or stainless steel and “tilting holders/stands” used to tilt the cases which are to be packed with the boxes.

An example of this that we saw in one of our client visits is shown in the image below:

The first step forward would be to add a conveyor after your folder-gluer’s compression belt so that your packing personnel can accumulate more boxes per meter of conveyor. This added conveyor is called an “accumulation conveyor.”

The accumulation conveyor reduces the speed of the box shingle and allows more boxes within the same time-frame. It’s more ergonomic, easier to keep up with the speed and far more convenient to work with multiple people.

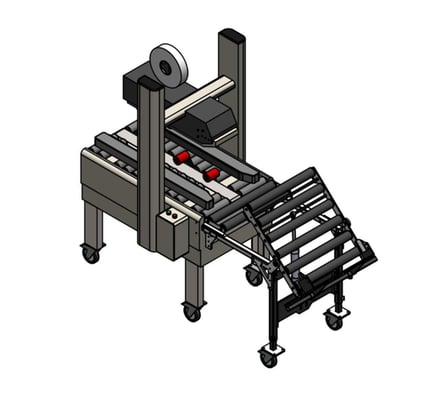

The next step would be to upgrade from your basic tables with tilting holders/stands to “actual tilting tables.” The 3D image below depicts an actual tilting table.

Typically, at this stage, those tilting tables do not yet have any automation or pneumatic but just the stand holding the case that you can push onto a conveyor.

Most often, we see those tilting tables locally-made and are used to hold the cases so that they’re tilted at an angle. The purpose of tilting the cases is to prevent the boxes from falling when placed into the case.

Another step forward would be adding a box turning feature.

This box turning feature allows you to rotate your boxes 90° to the left, or 90° to the right, and control your box orientation to meet the requested case packing configuration. If not turned, your boxes would come out standing up which would require you to manually turn them 90° to place them into the case.

So what a box turner really does is present/orient the boxes in a better way for the packing person(s) to facilitate the packing.

With the implementation of all the previous steps, you would now have the most common “Packing Help” or “Packing Aid” machine within the Manual category: A Collecting Table.

Displayed below is an image of a Collecting Table in action from one of our clients:

But just like with the traditional manual packing process, you still have to pack your boxes by hand on the Collecting Table and do the case flap closing, taping and ejecting yourself. It’s full manual work with no case management involved.

🚀 Quick summary: The most common “Collecting Tables” have a basic conveyor, a tilting table and most often a box turner which is the packing help/aid. No case management involved.

I listed and linked below the most popular Collecting Tables (or Packing Help/Aid) in the Western market that I’d urge you to take a few minutes to look at, and do your own research, on to ensure that you’re making the best decision for your company.

After all, we want to make sure that our clients have the most fitting solutions for their needs, even if that means not choosing IMPACK.

Definition: A packer uses a modernized packing solution that allows you to dramatically improve the efficiency, ergonomy and productivity of how you pack your boxes into cases by offering you automated case management capabilities.

IMPACK's 3 main folder-gluer packers are the Ergosa semi-automatic packer, the Virtuo automatic packer and the Virtuo + ACF fully-automatic packer.

What makes a packer, a packer is really the automated case management.

Anything without automated case management is simply a packing help or aid. With the case management feature that a packer offers, you can streamline your case ejection process so that your packing person(s) can focus on the packing and no longer has to perform the case flap closing, taping and ejecting as those actions are now all automated.

Once your case is full, all you do is push a button. That ejects the case semi-automatically or fully-automatically and you can take a new case. This is where you leverage to your advantage a lot of precious seconds, man-power and more output.

For example, If you’re packing 2-3 cases per minute with the automated case ejection, then you save 5 seconds per case which is 10-15 seconds per minute. This represents 15-25% more time for packing which thereby translates into more productivity on the whole packer line.

The case management allows you to add case handling to the process which means you can adjust the machine to a custom-case height that is ergonomic and productive — without the need of your packing person(s) to do any case management.

🚀 Quick summary: A Packer is when you have optimized your packaging area and included case management such that your case flap closing, taping and ejecting are all fully automated.

Now that we have laid this out clearly, who actually needs one of those packers?

In the simplest way possible:

If you’re considering equipment around folder-gluer lines, there are 3 questions to ask yourself:

Knowing what your products are, what volumes you produce, the speed at which you produce and the level of potential you have realized (or not) is the first step.

What does this all mean? Put simply, choosing the right machine depends on the thing you produce and how you go about producing it.

This includes the type, material, varnish, size, shape and thickness of your boxes.

Are you producing only folding carton or folding carton and corrugated/micro-flute?

And what type of boxes are you producing? 4-corner, 6-corner...etc.

Are you also producing crash-lock/auto-bottom boxes?

Knowing what you produce, how you produce it and your case-packing configuration will give you a very good understanding of what machine is right for what production.

Production volume is just a cool word for the number of boxes per folder-gluer line. Are you producing small volumes like 20,000-40,000 boxes/setup, larger volumes like 100,000-150,000+ or somewhere in the mid-range of 40,000-100,000?

The smaller your production volume is, the higher the % of setup time relative to actual production time. And the lower your production time, the slower your gluer speed would be because the operator has no time (or it is not worth the time) to tune your gluer to run faster.

Let’s take an example: If your setup takes you 15 minutes to run a box at 40,000 per hour, and you produce 10,000 boxes, then your production is 15 minutes. This results in a total production time of 30 minutes. At this point, you might as well just use the hand-packing mode with 1-2 minutes setup and run at 20,000 per hour.

So, what I want to draw your attention to is that there’s this tipping point where the setup time becomes less important because your production volume is high enough that your operator(s) and management will want to take the time to tune your folder-gluers to the maximum speed.

When I speak of potential, I am talking about whether you’ve pushed your folder-gluer to its maximum capacity.

Are you at the point where you can no longer produce more because you’ve reached your full capacity?

If you shouted “Yes” at the top of your lungs, then keep reading.

Now my question is Why?

If the reasons come down to limited shifts or man-power then we can agree that you’re capable of producing more, but you aren’t doing so...due to human limitations.

Today, a few companies use fully manual packing, most use Collecting Tables (box turners) and many are somewhere between semi-automated to fully-automated packers.

Are you in a situation where your boxes are coming out from your folder-gluer followed by your operators taking your boxes from there and putting them into some case by hand then pushing it somewhere where someone tapes it?

That was a mouthful! But if you answered “Yes,” then you probably are in the early stages of production where you have nothing behind the folder-gluer.

💡 Here’s a quick helpful tip: By simply adding another conveyor, you can slow down the speed compared to the exit of the gluer. Why so?

You can think about it in terms of density. When you increase your box density per meter of conveyor, you allow more box accumulation per meter of your conveyor. This leads to more boxes in the same time-frame.

More boxes mean more time for your packing person.

More time means the process is far more relaxed.

More relaxed means less room for error.

Assessing your current folding-gluing lines and any existing equipment around them is the second step. Sometimes all you need is some modifications such as adding more modules to the folder-gluer or having to go through the headache of changing the gluer altogether to a more recent one.

I love this article written by Jeff on PostPress that talks about choosing the right folder-gluer because it is a great place to start by looking at the 3 most important points that you need to know when choosing the right gluer.

An up-to-date gluer will usually imply a better automated, smoother and quicker setup that requires less manpower. Problem solved!

Let’s move on to the last question.

If you only have someone working one shift, 5 days a week on 1 folder-gluer line then you’re likely a family-owned business or a small-scale business owner.

Let’s be honest...in those types of situations, you don’t really need a new folder-gluer packer, let alone go down the full automation route.

Instead, you can invest in more ergonomic stations so people can enjoy coming to work. In addition, you can ramp up your productivity by getting an additional conveyor and two tilting tables with taping machines.

On the other hand, if you own 1 or 2 folder-gluers then you probably are in the range of doing a bit of everything but nothing too large in terms of volume or run-sizes. If this rings true to you, it could be lucrative to take your first step towards semi-automation.

Now, if you own 3 or more folder-gluers with dedicated lines, and you do a diverse array of multi-format boxes, then you are looking at a super sophisticated machine that is bigger, better and more specialized.

So, should you say “Yes” to a packer or “No?”

It all boils down to what your needs are.

Here is the concrete answer you’ve been waiting for:

If you can no longer increase the capacity of your folder-gluer because you have pushed your gluer to the limit, then ask yourself: Where exactly is the bottleneck taking place?

If the bottleneck is at the gluing and you have 1 packing person, then a simple packer like IMPACK’s Ergosa will not help you. However, a fully automatic packer, such as IMPACK's Virtuo + ACF could remove that one person and place them into higher value activities if the production volumes are fitting.

For example: Let's say you are producing 50,000 boxes per hour with 1 packing person, and you've reached the maximum speed of your gluer, this means that you cannot run faster with the gluer no matter what you do. Adding another person has no effect on the speed because the gluer has already reached its limit.

Therefore, you probably do not "need" a packer for small production volumes. That said, a packer could help for ergonomic reasons and you have to evaluate what ergonomics is worth for your company.

On the other hand, if you have large production volumes of 150,000 cartons or more, a fully automated packer might be a lucrative solution.

If the bottleneck is at the gluing, and you have 2 people packing, then you can reduce 1 or 2 people with the help of a packer.

For example: If your gluer is running at a speed of 50,000 boxes per hour with 2 people working hard to pack at that speed, and you already know that the folder-gluer has hit its limit, then you might want to consider adding a packer.

The packer would help you reduce 1 or 2 people and continue producing at the same folder-gluer speed. This means that you either need no packing person remaining or that the remaining person is packing twice as fast as before.

If the bottleneck is at the packing then whatever you do with the packer, it would be very helpful.

For simplicity, let’s take the same example: Your gluer is running at a speed of 50,000 boxes per hour with 2 people working hard to pack at that speed.

This time though, you know the folder gluer can run at 80,000 boxes per hour. In this specific situation, you may want to find a packer that helps you achieve your full potential of 80,000 boxes per hour either fully automatically or with 1 person only.

On the other hand, if you’re always in the small-volume ranges of 20,000-40,000 boxes per setup, then you typically won’t reach your folder-gluer’s top speed and this is where Collecting Tables like IMPACK's Packing Help Station might be of interest to you for ergonomic reasons or organizational efforts.

If you’re one of those people who skip straight to the end, here’s the quick takeaway:

The real tipping point between deciding whether you should add a folder-gluer packer or not is the setup time i.e. if your gluer could go faster and the packing people can follow, then this is where tuning your gluer would be a better first option than adding a packer to your folder-gluer.

👉 If your gluer could go faster, but you’re not sure how to make it run faster, we dedicated an entire article where you can learn step-by-step how to maximize your folder-gluer’s productivity with investing and with $0 investment.

However, if your gluer is far from reaching its full potential and your 2 packing persons are exhausted from working hard each day, then this is the best indication that it is time to explore some options of packers.

👉 If this rings true to you, find out the types of folder-gluer packaging equipment and the benefits they can offer for your company!

At IMPACK, we are incredibly passionate about educating our customers on what is right for them. This means doing everything we can to help you make the best and most fitting decision for your company. This also means talking about products that we do not sell since we’ve made it our goal to become the #1 go-to educational resource for folder-gluer packers.

I understand it is not easy to decide on a folder-gluer packer and it can be even harder convincing people in your organization on why you need one. Therefore, before you pull the trigger, I strongly suggest you check out the following article: What Folder-Gluer Packer is Right for You? (& How to Choose)

![Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]](https://impack.ca/hubfs/X21-011-1.png)

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?

![What Folder-Gluer Packer Is Right For You? [+VIDEO]](https://impack.ca/hubfs/X21-004.png)

If you're thinking of getting a packing aid, semi-automating your packing or thrusting into full-automation, then you might be asking yourself: What...

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...