Collecting Tables Vs. Ergosa Packer: Comparison & Evaluation

Let’s address the elephant in the room that most packaging producers avoid talking about :

With the growing complexity of the cardboard packaging market, the demand for custom-tailored boxes is increasing at a monstrous rate.

This requires not only ever more flexible folder-gluers but also more flexible packers that can adapt to those folder-gluers.

As a result, fully automatic packers cannot be considered due to their strict requirements and lack of flexibility for boxes that come in diverse shapes, sizes and formats.

It is, therefore, necessary to turn to more versatile packers that allow for product variation, regular adjustments and consistent corrections to meet the ever-evolving needs of the market.

“But what are those versatile packers and how do they work?”

“Do they offer the same advantages as fully automatic packers?”

The honest answer is that it all depends on the folder-gluer packer in question.

Our top sold folder-gluer packer, and our clients' favorite, is the Ergosa Packer.

This video & article talks about Impack's Ergosa packer: What it is, what benefits it has to offer and how to decide if it’s right for your company.

The Ergosa is a semi-automatic folder-gluer packer that optimizes the efficiency of your case packing process and maximizes your folder-gluer’s productivity.

A packer is one of the 4 main folder-gluer packaging equipment and peripheral solutions that can be added to a folder-gluer line.

A packer uses a modernized packing solution that allows you to dramatically improve the efficiency, ergonomy and productivity of how you pack your boxes into cases by offering you automated case management capabilities.

A packer is installed behind, or at the end of a folder-gluer, and after the pre-packing equipment.

In other words, a packer is installed at the end of the flow of the packaging equipment as shown in the image below.

A packer allows you to:

An Ergosa packer’s level of automation can range from a manual process to a semi-automated process.

More often than not, the Ergosa packers we produce include case management which makes them semi-automatic.

Hence the name, Ergosa: Ergo-nomic, semi-automatic.

Case management being included means that you have an automatic case ejection system, a manual or automatic flap folding system, pneumatic tilting tables and flap folding units. In other words, your cases are managed automatically.

Having your cases managed automatically means that your packing person(s) can focus on the packing and no longer has to perform the case flap closing, taping and ejecting as those actions are now all automated.

And what makes a packer, a packer is the automated case management capabilities that they offer.

Additional options and modes can be added to the Ergosa packer that allow you to increase your packing process’ level of automation.

The article “What’s the Difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers?” provides an in-depth explanation of the different levels of automation that folder-gluer packers can offer.

Related: What is the Ergosa’s Case Management System & How Does It Work?

%20%20(1).webp?width=624&height=482&name=ergosa-universal-vertical-transparent(6)%20%20(1).webp)

The Ergosa Packer is a high-performance and versatile modular box packing system. It is a semi-automatic packer with the performance of an automatic packer.

Its versatility and modularity make it IMPACK’s most sold folder-gluer packer.

The Ergosa packer is compatible with folding carton and corrugated board boxes

The Ergosa includes over 20 Years of Engineering Innovation. It features modules and tooling that increase productivity and ergonomics for various box types and case packing configurations.

For packaging producers who have limited space beyond their folder gluer, we also offer a compact configuration.

The Ergosa Compact 90° configuration is just 3.3m.

%20(1).webp?width=5000&height=2812&name=INH_ERGOSA%20CCM(TRANSPARENT)%20(1).webp)

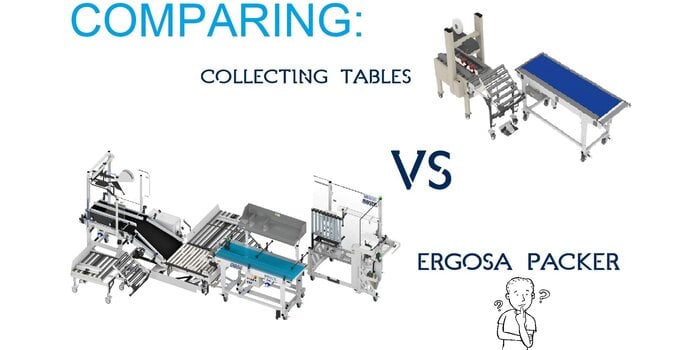

An Ergosa is not the right fit for you if you have small production runs of various, different box formats (5,000-10,000 boxes).

In this specific situation, a Collecting Table like IMPACK’s “Packing Help Station” or the other Collecting Tables on the market would be a much better choice. Some examples of the most popular Collecting Tables in western countries are Bobst’s Handypack GT, KBA Duran's Omega Pack Station and Tünkers' FAS 480.

Or you produce a large number of straight-line boxes with the same format per production run (several hundreds of thousands to millions) and your goal is to achieve the highest running speed available on the market.

In this case, an automatic packer like our Virtuo packer would be a better option if your production is one-row, one-layer packing.

And an Ergosa packer is not the best fit for you if you are exclusively doing banding/strapping.

This is because you would need a stacker such as IMPACK’s Everio stacker, or the many other stackers on the market, for the banding/strapping process.

Although we have developed a module on our Ergosa packer inspired by our PerPack Module that allows you to push batches of boxes into a banding/strapping machine so that they can be bundled together, the Ergosa packer is originally designed to pack boxes into cases and not to stack boxes for bundling needs.

Instead, an Everio stacker would be a better choice for banding/strapping.

Now if you are alternating between case packing and banding/strapping on the same folder-gluer, then the Ergosa could be a perfect fit. Otherwise, a custom project could be considered (especially if you have large production volumes).

Do you have more questions about the Ergosa packer and how it can improve your case packing process?

Or prefer to talk to an expert and get to see the Ergosa LIVE in action?

We’re here to help! Give us a call today and we'll offer you a free productivity analysis to help you discover how you can boost your folder-gluer productivity.

UP NEXT:

What’s the Difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers?

Let’s address the elephant in the room that most packaging producers avoid talking about :

.jpg)

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...

![Impack Packaging Ergosa Packer’s 3 Packing Modes | Complete Overview [+VIDEO]](https://impack.ca/hubfs/X21-026-2.png)

Are you looking to install a folder-gluer packer on your folder-gluer but want something that won’t make your company go broke?