What is a Collecting Table and How Can It Improve My Packing Process?

Are you looking for a packing system to help you improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach top packing...

10 min read

Stefan Badertscher

:

May 4, 2021

Stefan Badertscher

:

May 4, 2021

Let’s address the elephant in the room that most packaging producers avoid talking about :

The topic of Collecting Tables Vs. the Ergosa Packer: Which Should You Choose?

There is no doubt in my mind that you probably know of, or have stumbled across, one of the popular and long existing Collecting Tables.

Or maybe you own a Collecting Table yourself.

Collecting Tables are the most common, and longest existing, machines in the packaging industry. Some examples of the most widely present Collecting Tables in Western countries are Bobst’s Handypack GT, KBA Duran's Omega Pack Station and Tünkers' FAS 480.

At IMPACK, we manufacture and install folder-gluer packaging equipment and peripherals. Our “Packing Help Stations'' are similar to the Collecting Tables offered by other packer manufacturers. The Ergosa packer is our semi-automatic folder-gluer packer and our top sold machine.

“But which is better for me? A Collecting Table or an Ergosa Packer?”

“Do they both offer the same benefits?”

“Is the Ergosa really worth the extra dollars over a Collecting Table?!”

I am asked those questions dozens of times a week, in one form or another.

I get it.

In the end, every company wants to know which machine is better for them. Everyone wants to have the best folder-gluer packer that will become a money-making machine rather than a money-draining pit.

And these questions are all valid and important questions, but sadly, you are always left with the frustrating statement “it depends” or the “book an appointment with sales” nonsense.

In this article I am going to address those highly asked questions, once and for all, and in the most objective and unbiased way possible: A technical comparison of each machine’s working principles.

Before we jump into the comparison, if you’re not familiar with what a Collecting Table is or what the Ergosa packer is, I would strongly recommend you to check out the article “What's the Difference between Collecting Tables and the Ergosa Packer?” It clearly defines and describes each of those packing systems and their differences.

Alright. Let's now dive into analyzing how each packing system works and how the packing process looks like under each system.

Our analysis will focus on the two most important aspects of the packing systems:

We will begin by comparing the flow of boxes under each packing system. The flow of boxes refers to how the boxes move after the exit of the folder-gluer’s compression belt.

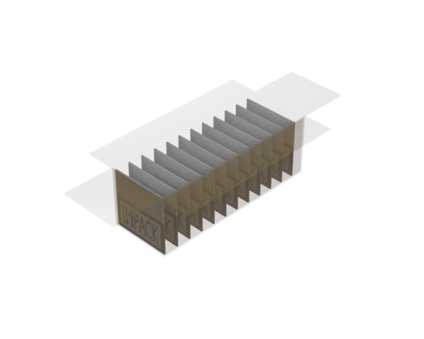

As you may already know, straight-line boxes are typically packed with the glue-line laying horizontal in the case just like the orientation of the IMPACK logo shown in the image below.

This means that the boxes need to be turned 90° until they are packed into the case.

How do both systems achieve this 90° turn?

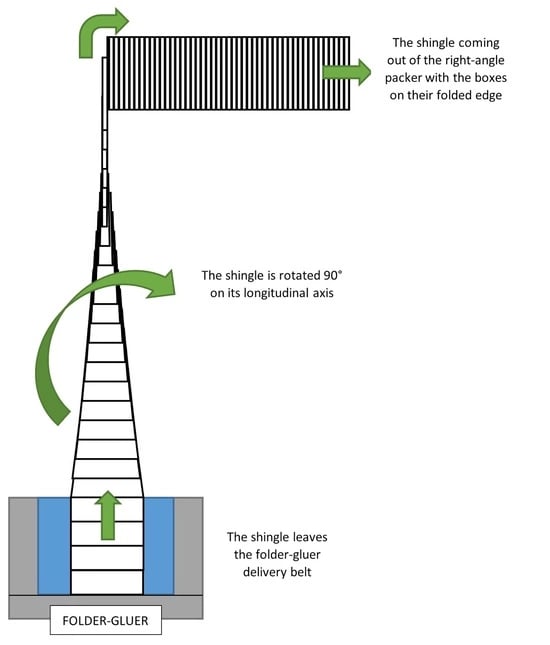

To make the comparison simpler, we created schematic drawings that describe the operation of each packing system.

At the exit of the folder-gluer’s compression belt, the box shingle enters the Collecting Table, “pinched” between the two belts, and travels for about 2-4 meters depending on the specifications of the packing system offered by the folder-gluer packer manufacturer.

As the box shingle moves through the belt section, it’s rotated 90° along its longitudinal axis which will result in the boxes being placed on their folded edge and at the end of the conveyor.

The accumulation conveyor, at the end of the Collecting Table, is approximately 2.5 meters long and — as shown above — is positioned perpendicular to the axis of the folder-gluer for the packing person(s) to "receive" the boxes on their folded edge.

This allows the speed of the shingle to be reduced to the minimum possible speed, hence allowing the maximum feasible time for the packing person(s) to pack the boxes.

Depending on the models and specifications of the Collecting Table, an automatically adjusting retaining system can apply a slight pressure on the new box shingle to keep them upright for easy packing.

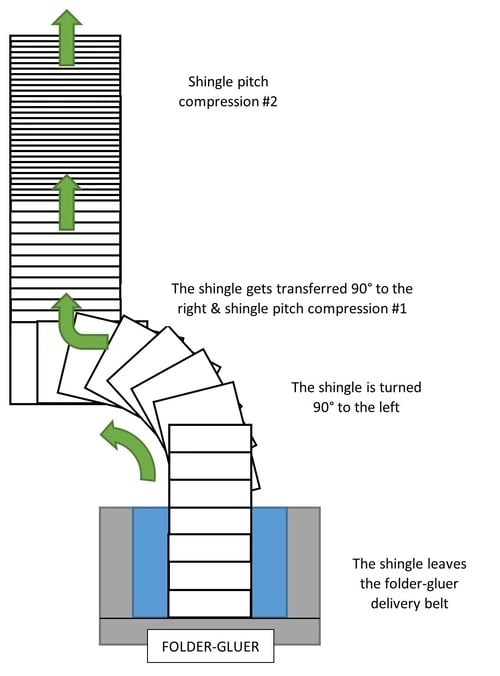

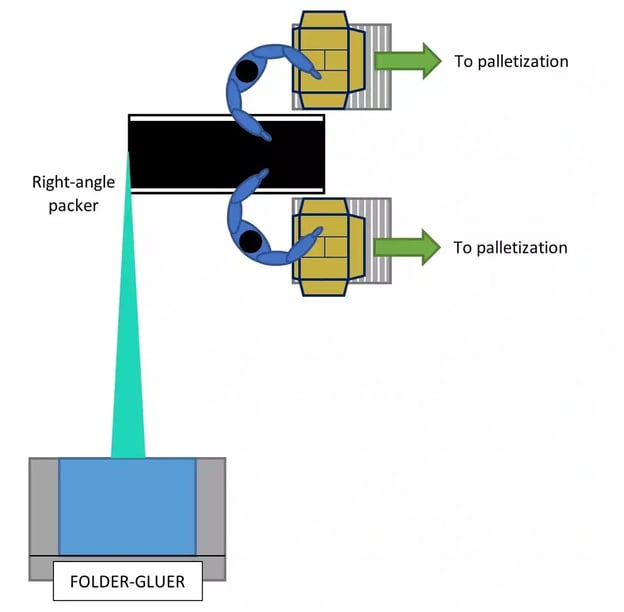

It is noteworthy to mention that all Ergosa packers are sold with one of their box turners (IN1, IN2A/B/C, IN3, INH, etc.). Since our most chosen box turner is the IN2A, we will consider the IN2A with the Ergosa in our analysis.

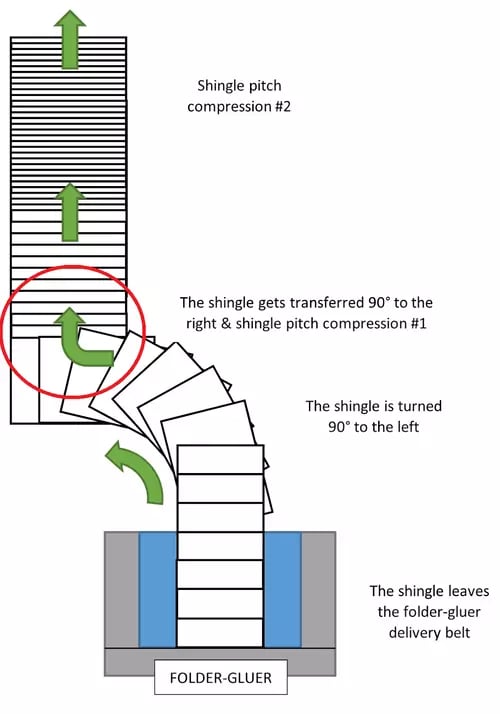

The drawing below will help you understand the process a little better:

At the exit of the folder-gluer’s compression belt, the box shingle enters the IN2A box turner, "pinched" between the rollers of the rotation section of the box turner. This will turn the box shingle 90° to the left.

Next, the box shingle leaves the rotation section and drops onto the conveyor with a direction of travel of 90° to the right of the rotation section. The red circle in the image below illustrates the point at which the box shingle gets dropped onto the conveyor.

The speed of the rotation section and the conveyor are both adjustable, thus allowing a regular, consistent and adaptable box turning.

Then, at the IN2A box turner's output, we obtain a shingle similar to the shingle at the exit of the folder-gluer but with the boxes turned 90° to the left.

The entire box turning machine (IN2A box turner) is a little less than 1.2 meters long and 1.4 meters wide.

If box turning is not necessary, the shingle can simply pass through the IN2A box turner without being turned.

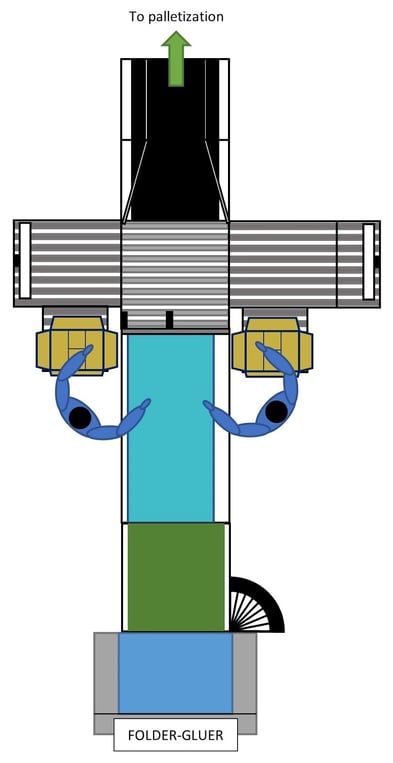

Once box turning is completed, the box shingle is transferred to the Ergosa's accumulation conveyor, which is a little more than 1.8 meters long and also adjustable in speed.

Therefore, the easily adjustable speeds of the IN2A box turner’s conveyor and the accumulation conveyor allow a substantially reduced speed of the shingle.

This also reduces the shingle pitch* and gives the operator the maximum possible time for packing.

At the end of the accumulation conveyor, there is a pneumatic end gate. This pneumatic end-gate is responsible for helping box accumulation and preventing box overflow.

The 3D image below shows the pneumatic end gate in the upper position.

*Shingle pitch refers to the distance between the boxes in the shingle.

Here is a table that summarizes our discussion and provides the key differences between Collecting Tables and the Ergosa packer in terms of box flow.

|

Collecting Table |

Ergosa Packer |

|

|

Box turning section length: |

|

|

|

Shingle accumulation conveyor direction: |

|

|

|

Accumulation conveyor length: |

|

|

Now, let’s examine the actual packing process offered by the Collecting Table vs. the Ergosa packer. The packing process refers to the process of packing the boxes into the case and the movement of boxes from the accumulated box rows into the case.

Here is an enhanced schematic drawing that will help walk you through the process more visually:

The packing person(s) (maximum 2 persons) will be allocated on either one side or both sides of the Collecting Table’s exit conveyor.

Ideally, a station for packing such as a tilting table will be available for each person to place the case on which is to be filled with the boxes.

Collecting Tables have only 1 packing mode available and it consists of the packing person(s) grabbing a batch of boxes and placing them into the case.

For each and every row in the case, the packing person(s) will have to repeat 4 to 8 times the operation of grabbing limited batches of boxes and placing them into the case. The number of times the operation is repeated all depends on how many boxes that respective packing person(s) can lift with their own hands.

In some cases, the packing person(s) may become skilled at grabbing a full row of boxes at once and placing it into the case. That said, we rarely see it happening.

With Collecting Tables, you still need to do the lifting, case ejecting and packing yourself. There is absolutely no way around it.

In the end, your packing person(s) will always have to lift all the boxes and place them into the case in one way or another because there is absolutely no case management involved. This represents about 3-5 tons of carton material per shift.

Just like with the traditional manual packing, the operation of the Collecting Table involves manual work and hand movements that increase the chances of Repetitive Strain Injury (RSI).

Once a case is fully packed, the packing person(s) either tapes the case by hand or pushes the case into a case sealer.

Let’s now examine the packing process offered by the Ergosa packer.

Before we get into it, you should know that the Ergosa is a versatile machine with various options and multiple modes that can be adapted for very different productions and industries. Depending on the box style you’re running, you can choose the most suitable packing mode available.

Regardless of your production, industry or box style, the overarching principle of the Ergosa packer under all packing modes is always the same: The Ergosa packer offers your packing personnel the capability to pack a full row of boxes, in one single motion, by “sliding” or “pushing” the boxes into the case. No lifting of loads is required as with the traditional manual packing (i.e. Collecting Tables).

This, thereby, highlights the 3 main differences between the Ergosa packer and the Collecting Tables in terms of the packing process:

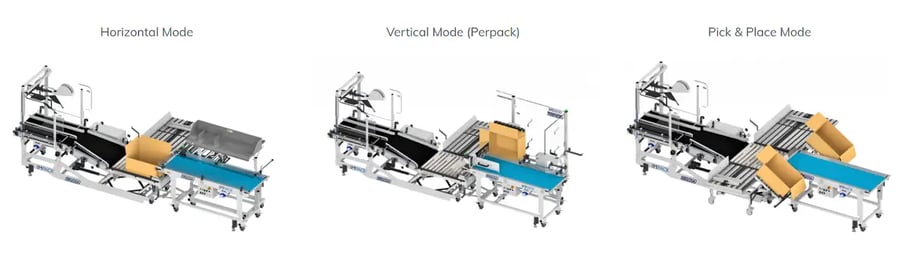

The Ergosa packer offers 3 main packing modes: The “Horizontal Mode,” the “Vertical Mode” and the “Pick & Place (or Manual) Mode.”

In addition to these 3 main packing modes, we offer other modes such as the “Tray Holder Mode” for very small boxes and adjusted versions of the vertical mode that are adapted to work with banding/strapping machines.

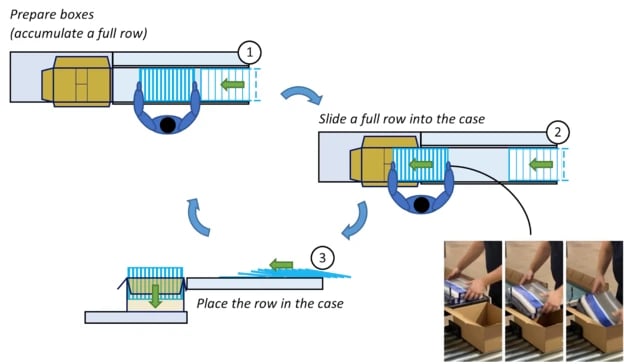

The Horizontal Mode allows you to pack a full row of boxes, in one single motion, by sliding the full row of boxes into the case. This “sliding movement” capability is depicted in the image below:

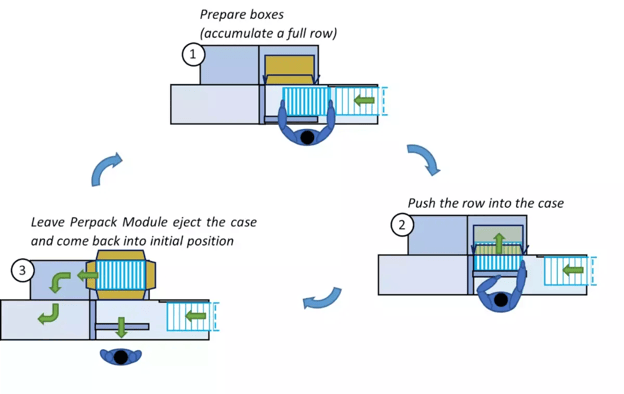

The Vertical Mode allows you to pack a full row of boxes, in one single motion, by pushing the full row of boxes into the case using the PerPack Module. This “pushing movement” capability is depicted in the image below:

The Pick & Place Mode (or Manual Mode) is the same hand-packing mode that the Collecting Table offers. It offers 1 or 2 pick and place stations for 1 or 2 packing person(s). The Pick & Place/Manual Mode is used when the Horizontal and Vertical Modes do not suit a specific box type or case packing specification.

Just like the Collecting Tables, this mode increases the workload on employees, as it involves manual work, and hand movements that increases the risk of Repetitive Strain Injury (RSI).

A final important point that cannot be overlooked is the case management system offered by the Ergosa packer.

As mentioned earlier, the Ergosa packer offers automated case management capabilities that Collecting Tables don’t.

No matter which packing mode you use, your full cases will always be ejected fully automatically and sent to the case sealer even if you are hand-packing with 2 people.

That is to say, the Ergosa packer streamlines your case ejection and manages your case handling process fully automatically i.e. your packing person(s) can focus on the packing as the case flap closing, ejecting and sealing actions are now fully automated.

The table below summarizes our analysis and provides the key differences between Collecting Tables and the Ergosa packer in terms of the packing process.

|

Collecting Table |

Ergosa Packer |

|

|

Number of packing person(s): |

|

|

|

Packing modes: |

|

Offers 3 main packing modes:

|

|

Packing movement: |

|

Regardless of the packing mode, you can pack a full row of boxes, in one single motion, into the case.

|

|

Case holding: |

|

|

|

Case ejection system: |

|

|

The two tables (Table 1 and Table 2) of the flow of boxes and the packing process summarize the key differences between Collecting Tables and the Ergosa Packer.

A Collecting Table is a simple machine that can be a great starting point for your production. It is simple because it always uses the same packing mode. IMPACK’s Collecting Table is the Packing Help Station. Some of the other most common Collecting Tables in the Western market include Bobst’s Handypack GT, KBA Duran's Omega Pack Station and Tünkers' FAS 480.

The Ergosa packer is a versatile and modular machine with more packing modes and a multitude of options that can be adapted to work with any production, box style or industry. It is IMPACK’s most sold folder-gluer packer and one of the only semi-automatic packers on the market.

“So, should I choose a Collecting Table or the Ergosa packer?”

“Which is right for me?!”

Here is the honest and direct answer:

Do you have more questions that you want answers for before you decide which packing system is right for you?

And would you like to see our Collecting Table or the Ergosa packer in action?

Give us a call today and let’s talk folder-gluer packing systems!

UP NEXT:

What is an Ergosa & How Can It Improve My Packing Process?

What Are the Ergosa Packer’s Main Packing Modes & What Benefits Do They Offer?

Are you looking for a packing system to help you improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach top packing...

With the growing complexity of the cardboard packaging market, the demand for custom-tailored boxes is increasing at a monstrous rate.

![Semi-Automatic Vs. Fully-Automatic Packers: Which Is Better? [+VIDEO]](https://impack.ca/hubfs/ezgif.com-gif-maker%20(50).jpg)

If you’re a carton box manufacturer that’s searching for ways to improve your folder-gluer’s productivity, you’ve probably come across several...