Impack Packaging's INH Box Turner: A Complete Review

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...

8 min read

Han Guo

:

August 27, 2021

Han Guo

:

August 27, 2021

This article will show you the most effective way to calculate how long it will take to get your return from investing in packaging equipment.

Return on Investment (ROI) is a profitability metric that you likely use in your day-to-day life, even if you’ve never thought about it before.

Whether you’re investing in stock options, buying a new house, purchasing a folder-gluer, or investing in folder-gluer packaging equipment, knowing how to calculate your return on investment (ROI) is important.

So, what’s ROI?

ROI is the annual return you’ll receive from an investment.

Essentially, it informs you how much profit you can expect from investing in something.

For example, if your bank is offering you a 10% interest rate, then you know that if you invest $100 today, you’ll have $110 a year from now ($100 is your investment paid back and $10 is the return over your investment i.e. 10% is your ROI).

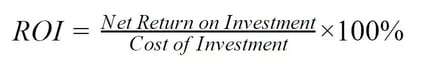

The formula to calculate ROI is:

The payback period is the time needed to recover your investment.

That is, it is the length of time needed before your investment breaks even.

For simplicity, let’s go back to our previous example:

Today, you’ve invested $100 in your bank. This time your bank offers you an annual return of $25 (or 25% ROI).

If you get a payback of $25 every year, then it will take you 4 years to recover your $100 investment. Hence, your payback period is 4 years.

The key difference between ROI and payback period is that ROI represents the return from your investment whereas payback period represents the expected time to get your return from your investment.

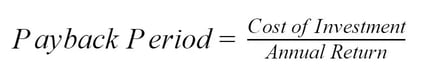

The formula to calculate Payback Period is:

It is important for you to know that the ROI can only be calculated by clients themselves because only the client knows their "actual" return on investment.

That said, we can calculate the "maximum" payback period.

“Why maximum?”

Because the annual return also involves the profit that a client will make from their investment which substantially varies from one client to the other.

Therefore, the payback period that we calculate will be entirely based on the amount of money saved using packaging equipment.

This means that the "actual" annual return will most likely be higher than the amount of money saved.

So, the payback period that we calculate will probably be longer than what your "actual" payback period would be.

Hence why it is the "maximum" payback period you can expect from investing in packaging equipment.

What is a good payback period?

The best payback period is the shortest one feasible. The longer the payback period, the greater the risk. But that’s not the full story. I’ll get to that in a minute.

7 factors affect how long it would take to get your return from investing in packaging equipment:

Folder-gluer’s cost.

Labor cost.

Number of working shifts per day.

Number of working days per week.

Number of working weeks per year.

How much productivity improvements can be achieved.

The current state of the economy.

Let’s quickly examine those factors. We won’t dive into the 3rd, 4th, and 5th factors since they are self-explanatory.

The folder-gluer’s cost refers to the price of the folder-gluer, its operating costs, and its maintenance costs.

This amounts to approximately 100-120€ per hour.

The labour cost represents the total amount of money spent on your packing staff or operator(s).

In other words, the total wages, benefits, payroll taxes, human resources management, training, etc. that are paid to, and for, all your packing staff/operators. This includes both direct and indirect costs.

Typically, 2 or more employees are needed at the end of your folder-gluer’s compression belt even if you have a Packing Help Station/Collecting Table.

Those employees are called packing staff, packing persons, operators, or sometimes informally referred to as “packers” (although the term ‘packers’ is more appropriate when talking about packing systems).

IMPACK’s Ergosa Packer, Virtuo Packer, and Everio Stacker can probably help you reduce 1 or more packing person(s) or completely automate your packing process such that no packing personnel are needed.

Instead, your packing staff can focus on higher value-added activities.

With IMPACK’s Ergosa packer, for example, you can reduce 1 packing person. This reduced employee’s cost is saved.

We can simply use this employee’s salary as the saved labor cost which is the annual return in the payback period formula.

Depending on which country your company is in, this number can vary drastically.

In addition, you also save all the administrative fees related to the cost of that employee i.e. benefits, payroll taxes, human resources management, training, etc.

In countries with high employee turnover, finding employees skilled in packing is more challenging and therefore labor costs tend to be significantly higher.

A folder-gluer’s productivity refers to the existing capabilities of a folder-gluer.

The words "productivity, “output,” and “capacity” are often used interchangeably but they mean the same thing.

To keep things simple, we will measure productivity as the number of boxes produced per day.

That is to say, increased folder-gluer productivity, output, or capacity represents more packed boxes or full cases onto a pallet per day.

Although we said that the best payback period is the shortest one possible, there's a caveat to this statement.

How short is “short” all depends on the state and health of the general economy, as well as, your local economy.

During times of economic growth, a payback period of 3-5 years could be justifiable.

However, if the economy is in a crisis (e.g. 2008-2010), a payback period of 6 months or less may not even pass!

Now that we’ve discussed what factors influence the payback period, let’s take a look at some real-life examples of payback periods from real IMPACK clients.

IMPACK’s packaging equipment can help you earn money in two ways: 1) Reducing your labor costs and 2) Increasing your folder-gluer’s productivity.

To help you better understand what payback period you can expect from IMPACK’s equipment, we will show you examples of payback periods from our clients and illustrate exactly how those payback periods are calculated.

Furthermore, to keep as many variables controlled as possible, all the examples use real data given to us from real clients.

The 2 examples below will demonstrate 3 different scenarios:

One packing person reduced and no increase in productivity (assuming you have 2 packing persons).

No packing person(s) reduced and 25% increase in productivity (assuming you have 2 packing persons).

One packing person reduced and 25% increase in productivity (assuming you have 2 packing persons).

Cost of Ergosa C Packer (with all 3 packing modes) + IN2 Box Turner: Total cost is approximately 93,000€.

Breakdown of client’s costs:

Folder-gluer’s cost (maintenance, electricity, machine price, etc.):

100€ per hour.

Labor cost (including all direct and indirect costs):

22€ per hour.

Number of shifts per day (1, 2, 3, or 4 shifts):

1 shift of 8 hours per day.

Working days per week (5 or 7 days):

5 days per week.

Working weeks per year (48-52 weeks):

50 weeks per year.

🔍 Related: What are the Ergosa's 3 Packing Modes (& Which Mode is Best For Your Production?)

Scenario #1: One packing person reduced and no increase in productivity (assuming you have 2 packing persons)

Labor cost per year: (22€ per hour x 1 packing person) x 8 hours per day x 5 days per week x 50 weeks per year = 44,000€ per year.

The 44,000€ is now the annual return because this labor cost is saved by reducing 1 packing person.

Thus, the payback period will be 93,000€ / 44,000€ = 2.1 years.

Scenario #2: No packing person(s) reduced and 25% increase in productivity (assuming you have 2 packing persons)

Labor cost per year: [100€ per hour + (22€ per hour x 2 packing persons)] x 25% x 8 hours per day x 5 days per week x 50 weeks per year = 72,000€ per year.

Thus, the payback period will be 93,000€ / 72,000€ = 1.3 years.

Scenario #3: One packing person reduced and 25% increase in productivity (assuming you have 2 packing persons)

Labor cost per year: [100€ per hour + (22€ per hour x 1 packing person)] x 25% x 8 hours per day x 5 days per week x 50 weeks per year + 44,000€ (labour cost per year of 1 packing person) = 105,000€ per year.

Thus, the payback period will be 93,000€ / 105,000€ = 0.9 year.

Ergosa C Packer (with all 3 packing modes) + IN3 Box Turner + MFA Batch Inverter: Total cost is approximately 320,000€.

Breakdown of client’s costs:

Folder-gluer’s cost (maintenance, electricity, machine price, etc.):

100€ per hour.

Labor cost (including all direct and indirect costs):

24€ per hour.

Number of shifts per day (1, 2, 3, or 4 shifts):

3 shifts of 8 hours per day.

Working days per week (5 or 7 days):

5 days per week.

Working weeks per year (48-52 weeks):

48 weeks per year.

Scenario #1: One packing person reduced and no increase in productivity (assuming you have 2 packing persons)

Labor cost per year: (24€ per hour x 1 packing person) x 3 shifts per day x 8 hours per day x 5 days per week x 48 weeks per year = 138,240€ per year.

The 138,240€ is now the annual return because this labor cost is saved by reducing 1 packing person.

Thus, the payback period will be 320,000€ / 138,240€ = 2.3 years.

Scenario #2: No packing person(s) reduced but 25% increase in productivity (assuming you have 2 packing persons)

Labor cost per year: [100€ per hour + ( 24€ per hour x 2 packing persons)] x 25% x 3 shifts per day x 8 hours per day x 5 days per week x 48 weeks per year = 213,120€ per year.

Thus, the payback period will be 320,000€ / 213,120€ = 1.5 years.

Scenario #3: One packing person reduced and 25% increase in productivity (assuming you have 2 packing persons)

Labor cost per year: [100€ per hour + ( 24€ per hour x 1 packing person)] x 25% x 3 shifts per day 8 hours per day x 5 days per week x 48 weeks per year + 138,240€ (labor cost per year of 1 packing person) = 316,800€ per year.

Thus, the payback period will be 320,000€ / 316,800,€ = 1 year.

As we’ve seen, the payback period is a valuable indicator of whether an investment is worth making.

We talked about what the payback period is, how you can calculate it, and what factors affect the length of time it would take before you get your return from investing in packaging equipment.

We also examined 2 examples with 3 different scenarios that illustrate very different payback periods.

It's safe to say that the payback period is an effective measure of investment risk.

💡 Here are 4 important takeaways you need to consider:

The best payback period is the shortest one possible. How short is “short” all depends on the state of the economy.

Ask your packaging equipment supplier (whether you choose to go with IMPACK or another manufacturer) about the expected payback period of the machine you’re interested in.

Remember: The price of packaging equipment is irrelevant given that the payback period is the real measure of your gain/loss from investing in packaging equipment.

Production volume plays an important role: If you’re not producing sufficient output, the payback period will be longer and hence the investment is riskier.

👉 Find out what packing speeds you can reach with IMPACK’s packaging equipment.

👉 Discover the top 7 hidden costs when buying packaging equipment and how you can avoid them.

👉 Learn how much does folder-gluer packer/stacker cost?

We don’t blame you! Read our Top 10 FAQs About IMPACK’s Packaging Equipment.

If you still can’t find what you’re looking for or have questions that are specific to your company, contact us today! IMPACK’s experts would love to help!

.jpg)

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...

![Automatic Vs. Fully-Automatic Packers: Which Should You Choose? [+ VIDEO]](https://impack.ca/hubfs/X21-054-1.jpg)

If you’re searching for ways to improve your folder-gluer productivity, you’ve probably noticed that some of your competitors have Semi-Automatic...

One of the first questions that every carton box manufacturer asks our company is: What folder-gluer packer is right for me?