Folder-Gluer Packers Vs. Stackers: Which Packaging Solution is Best For You?

If you’ve been searching for ways to improve your folder-gluer productivity and reach higher packing speeds, you’ve probably noticed that some of...

8 min read

Mathieu Tremblay

:

March 17, 2021

Mathieu Tremblay

:

March 17, 2021

![Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]](https://impack.ca/hubfs/X21-011-1.png)

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?

We’re here to help!

As manufacturers and installers of folder-gluer packaging equipment and peripherals, the #1 question we get asked is 👇:

“What folder-gluer packer is right for me?”

This is a very common question because everyone wants answers to their specific problems so that they can make their own decisions.

So, this article + VIDEO are my attempt to break down our different types of folder-gluer packers so that you can decide, on your own, which packer is a good match for you.

First — it is important for you to know that our folder-gluer packaging equipment and peripherals fall into 4 main families:

And each of those 4 families includes distinct solutions with varying degrees, scopes and levels of automation. We classify those levels of automation into 4 categories:

Manual packing

Semi-Automated packing

Automated packing

and Fully-Automated packing.

Those categories are our own definitions and not dictionary definitions, but they are “informally accepted” as the industry standard.

We will compare our 3 folder-gluer packaging equipment on 3 key aspects:

Their scope of automation.

The type of process they involve.

What machine is best fit for what production?

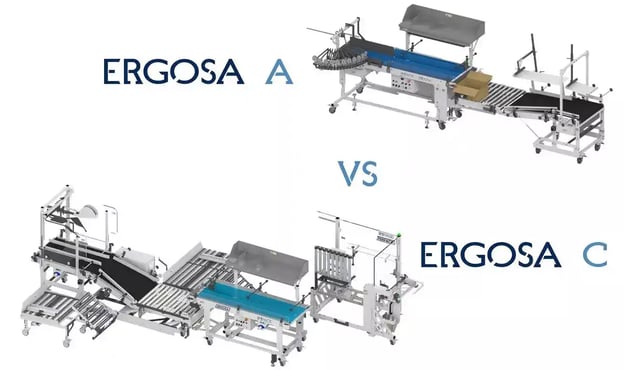

The Ergosa is a folder-gluer packer that can range from a manual to a semi-automated process depending on the options and modules installed.

The vast majority of the Ergosa packers we produce include case management which makes them semi-automated.

Hence the name, Ergosa: Ergo-nomic, semi-automatic.

Case management being included means that you have an automatic case ejection system, a manual or automatic flap folding system, pneumatic tilting tables and flap folding units.

🔍Related: What is the Ergosa’s Case Management & How Does it Work?

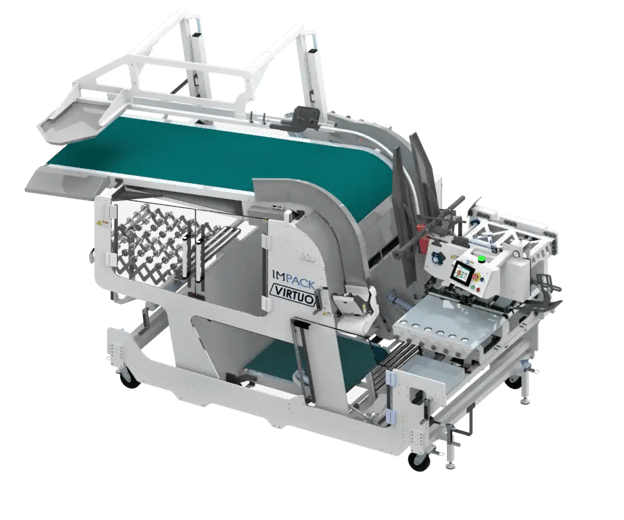

The Virtuo is a folder-gluer packer that can range from an automated to a fully-automated process.

In its basic and most common product offering, the Virtuo is an automated packer.

Adding the optional Auto Case Feeder (ACF) Module to the Virtuo packer is what pushes the Virtuo’s scope of automation into the fully automated category, hence making the Virtuo a fully auto packer with a fully automated process.

That being said, the ACF is a fully-fledged machine in itself and not just a module. Thus, the cost of going from an automated process to a fully automated process can be exponential.

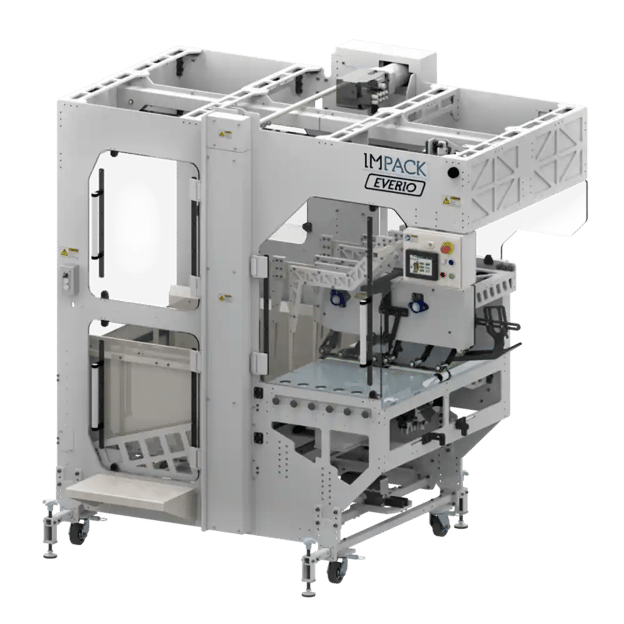

The Everio is a folder-gluer stacker that is always offered as a Fully-Automatic machine for all boxes that do not require inversion. Typically these are straight-line boxes or envelopes.

As an optional add-on, we also offer a Semi-Automatic inversion module on the Everio stacker for crash-lock/auto-bottom boxes. But even the Semi-Automatic inversion module uses the automatic counting and stacking mechanism of the Everio stacker. This is all to say that the Everio is, in most cases, a Fully-Automatic machine.

The purpose of developing this semi-automated process for the Everio is to increase the versatility of the Everio so that it can adapt to all possible boxes.

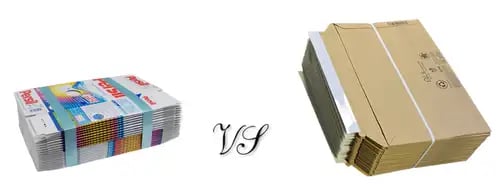

The Ergosa and Virtuo are folder-gluer packers that facilitate a case packing process. A packer utilizes a modernized packing process that packs boxes into cases, streamlines the case ejection and manages case handling.

The Everio, on the other hand, is a folder-gluer stacker that meets bundling needs. A stacker is similar to a packer in the sense that it takes a shingled stream of folded cartons, counts them and bundles them, but the output batches don’t end up in a case.

Instead of packing the boxes into a case, as done with a folder-gluer packer, a stacker accumulates the boxes vertically and then sends them for banding/strapping.

In other words, depending on your production processes, you either pack your boxes into cases (case packing) using a folder-gluer packer or stack your boxes to be banded/strapped together (box bundling).

It is either one or the other; however, some clients do both processes on the same folder-gluer.

We also developed a module on the Ergosa packer inspired by our PerPack Module, that allows you to push batches of boxes into a banding/strapping machine so that they can be bundled together.

So, the Ergosa folder-gluer packer could pack the boxes into cases as a packer would do, or be adapted to act as a folder-gluer stacker to stack boxes that are to be banded/strapped together.

We, here at IMPACK, are not experts in the banding/strapping process; we rather rely on devices from our renowned partners, such as ATS, Mosca or SMB/Signode, that do the banding/strapping.

Mosca is dedicated to strapping and ATS is dedicated to banding. SMB offers both materials.

This article by ATS offers a fair comparison on the difference between banding and strapping because it clearly outlines the differences between both materials and addresses which technology is better for what production.

I will keep this as short and as simple as possible!

If you are exclusively doing case packing, then either the Ergosa packer or the Virtuo packer is the best fit for you.

This is because the Everio is a folder-gluer stacker and not a packer. It cannot do case packing.

An Ergosa packer is a better choice for you if you have a wide and diverse variety of box formats, small to medium boxes, shorter production runs or complex boxes that require constant adjustments.

A Virtuo packer is a better choice for you if you have a more limited and similar variety of box formats, medium to very large boxes, longer production runs or easy products that do not need constant adjustments/modifications.

That said, Virtuo packers can only pack one row, one layer into cases.

If your typical production is multi-row, multi-layer case packing then the Virtuo is not the right fit for you.

Instead, Bobst’s Carton Pack 4, Heidelberg’s Diana Packer, KBA Duran's Omega Pack Station or Ace Machinery’s Sig-Pack would be a better fit. Those are just some examples of the most common multi-row, multi-layer auto-packers on the market.

It is noteworthy to mention that all these other “multi-row, multi-layer auto-packers” process the cartons through a curved arch which unfortunately makes them incompatible with corrugated cartons. Here — IMPACK’s Automatic packer, the Virtuo, would be the most fitting solution. We do not say this out of bias towards our packing solutions, but simply because the Virtuo has the distinctive ability to process these corrugated cartons without curving them!

At IMPACK, we are dedicated to manufacturing and designing innovative packaging equipment that no one else does. If other companies sell them, we don’t make them.

If you are exclusively doing banding/strapping, then the Everio stacker is the best fit for you.

Arguably, the Ergosa packer can be adapted to do the bundling too, but the Ergosa is a better fit for when you’re exclusively doing case packing or alternating between case packing and banding on the same folder-gluer.

After all, the Ergosa is a packer designed to pack boxes into cases.

A Fully-Auto Everio stacker is a better choice if you’re in the e-commerce industry, you produce wine-in-box, or you do fairly simple cartons.

A Semi-Auto Everio stacker is a better choice if you need to produce a small proportion of crash-lock/auto-bottom boxes (which have to be inverted into batches) in addition to the simple cartons you regularly produce.

The semi-auto modules of the Everio are an important addition to consider. It gives you the versatility to produce these crash-lock/auto-bottom boxes without having to remove the packer or process them on another folder-gluer.

You also leverage performance gain as the semi-automatic Everio allows you to count and bundle the batches prior to the manual inversion.

If you do both case packing and banding/strapping on the same folder-gluer, then the Ergosa packer could be a perfect solution.

Otherwise, depending on your product mix and specific requirements, a custom project could be a better choice (especially if you have large production volumes).

Each of these folder-gluer packers and stackers usually require a device to better present/orient the shingle of boxes so as to facilitate the packing/stacking process. This device is called a “box turner.”

The purpose of a box turner is to allow you to rotate your boxes 90° to the left, or to the right, and control your box orientation to meet the requested case packing configuration.

If not turned, your boxes would come out standing up which would require you to manually turn them 90° to place them into the case.

If you are considering an Ergosa A packer, then your 2 available options are the IN2 and the INH box turners.

The box turner is integrated to the Ergosa A’s conveyor to reduce cost and floor space.

The INH is our newly developed turner since 2020. It is the most efficient and the best fit for the Ergosa A packer. That said, it is not as versatile as the IN2 just yet. In cases where the INH won’t fit, the IN2 is also an excellent second choice.

If you are considering an Ergosa C packer, then your 4 available options are the IN2, IN3, IN1 and INH box turners.

Almost every single Ergosa C packer is sold with an IN2 as it is the most cost-effective solution for box turning. The INH is the latest model and will be more widely available and readily chosen as the preferred box turner from 2021 onwards.

The IN3 is also available but it would honestly be unnecessarily expensive for an Ergosa production line. Yes — it has the advantage of keeping the centerline from turning to a straight-through setup, but it is longer than an IN2 and the third rotation is rarely used on an Ergosa.

The IN1 is another available option with the Ergosa C packer but it is limited to specific types, shapes and sizes of cartons. It also can’t be installed on narrow compression belts and requires more human intervention. But it has the advantage of being by far the least expensive solution.

The INH will be available in full scope by the end of 2021 but requires a further assessment from our sales team to validate the fit. If the fit is right, it is the best solution for turning your boxes.

If you are considering a Virtuo packer, then your 2 available options are the IN3 and IN2 box turners.

The best fit most of the time is the IN3 box turner — either in its standard size or the XL size depending on your production. It has the advantage of keeping the centerline from turning to a straight-through setup, which is more important on an automated or fully automated line.

To reduce your costs, an IN2 is another available option but will require moving the folder-gluer packer if you need to switch from one orientation to the other, and this means longer setup times. But if your boxes always need turning then the IN2 will be as fixed as an IN3!

If you are considering an Everio stacker, then your 2 available options are the IN2 XL and IN3 box turners.

The best fit would be an IN2 in XL size.

An IN3 could be an interesting solution to keep the centerline, but most of the time the carton specifications are too large even for the IN3 XL size.

And although an IN3 XXL could be developed, it would become too expensive and too large to be a viable option in our opinion.

While there is no correct answer for all companies as each company’s needs are unique and different for every company, there are a few general guidelines that you can take away from this article.

👉 If you exclusively do case packing, then either the Ergosa packer or the Virtuo packer is the best solution.

Ergosa packer is a better choice if you have a diverse variety of box formats, small to medium boxes, shorter runs and complex boxes.

Virtuo packer is a better choice if you have similar box formats, medium to very large boxes, longer runs and easy products.

👉 If you exclusively do banding/strapping, then the Everio stacker is the best solution.

Fully-Automatic Everio is a better choice if you produce fairly simple cartons.

Semi-Automatic Everio is a better choice if you produce fairly simple cartons and a small proportion of crash-lock/auto-bottom boxes.

👉 If you do both case packing and banding/strapping, then the Ergosa packer is the best solution. Otherwise, a custom solution could be considered.

All folder-gluer packers and stackers usually need a box turner and the right choice of the box turner depends on which folder-gluer packer or stacker is selected.

INH is the best fit if Ergosa A packer is selected.

IN2 or INH is the best fit if Ergosa C packer is selected.

IN3 or IN3XL is the best fit if Virtuo packer is selected.

IN2 XL is the best fit if Everio stacker is selected.

Not sure on how to go about choosing a folder-gluer packer?

Read our article “What Folder-Gluer Packer is Right For You?“ It breaks down the pros and cons of the different types of folder-gluer packers and important things to consider before choosing a packer.

UP NEXT:

What Folder-Gluer Packer is Right for You? (& How to Choose)

If you’ve been searching for ways to improve your folder-gluer productivity and reach higher packing speeds, you’ve probably noticed that some of...

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

Let’s address the elephant in the room that most packaging producers avoid talking about :