Collecting Tables Vs. Ergosa Packer: Comparison & Evaluation

Let’s address the elephant in the room that most packaging producers avoid talking about :

10 min read

Mathieu Tremblay

:

May 12, 2022

Mathieu Tremblay

:

May 12, 2022

Today’s cardboard packaging market demands more and more personalization with shorter production runs and boxes with shapes as diverse as they are varied.

This requires not only ever more flexible folder-gluers but also more flexible packers that can be integrated onto those gluers and be adaptable enough to meet the market’s complex needs.

“Can a folder-gluer packer actually boost my folder-gluer’s productivity?”

“Is there an unbiased comparison between the different folder-gluer packers out there?”

“How do I know which folder-gluer packer is right for me?”

As manufacturers and installers of folder-gluer packaging equipment and peripherals, we get asked those questions all the time.

This VIDEO + ARTICLE are my effort to provide a clear, unbiased and objective comparison between the 4 categories of folder-gluer packers and expose the true differences without holding anything back.

My approach will be straightforward: I will define each category, list the pros and cons of each, compare the 4 categories and then back off so that you make your own decision.

Before I define each category, it’s noteworthy to mention that those are our own definitions and not dictionary definitions. Each category of automation consists of a wide range of packing systems with varying features, benefits and capabilities.

However, those definitions are informally embraced as the industry-standard and most solutions on the market squarely fit within one of those 4 categories.

1. Manual packing: The manual packing process is the lowest level of automation and is usually the starting point of a folder-gluer operation. It is the traditional packing method where the entire packing process is done manually. No automation involved and no case management involved. The most common packing system in the manual category is a packing help/aid to the traditional packing process, such as the many popular Collecting Tables that exist on the market.

IMPACK’s Collecting Table is the "Packing Help Station.”

2. Semi-Automated packing: The semi-automated packing process is one that includes at least one automated function.

For example, IMPACK’s Ergosa is one of the only semi-automatic packers on the market. The Ergosa packer is semi-automatic because it includes an automated case management process.

3. Automated packing: The automated packing process is where the machine becomes the key factor of the packing process and the operator is now limited to performing background tasks such as feeding the packer with empty cases or managing full cases.

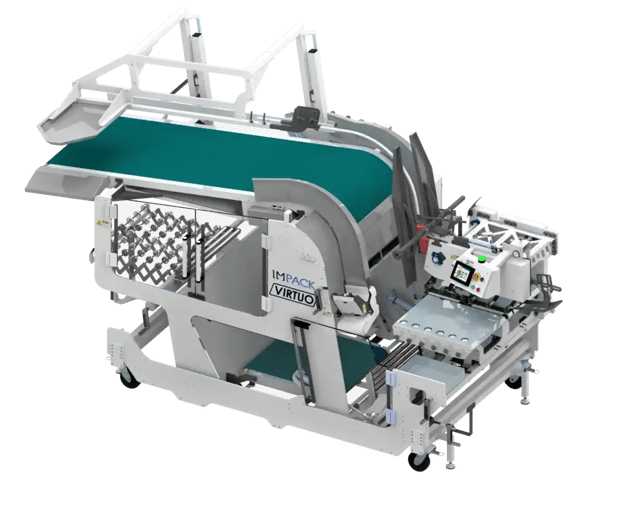

IMPACK’s auto packer is the “Virtuo.”

4. Fully-Automated packing: Of all 4 categories, the fully-automated packing process is the highest possible level of automation. The whole packing process here becomes automatically managed without requiring the presence of an operator (or any other humans) while running. The operator is only involved in make-readies/setups.

IMPACK’s fully-auto packer is the “Virtuo + ACF,” and it is the only 100% fully automatic folder-gluer packer that exists on the market for both corrugated and carton boards.

If you want a more in-depth explanation of the 4 different levels of automation, our article “What’s the Difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers?” digs deeper into those 4 automation levels and explicitly describes how they compare to one another!

Full disclosure: Because there are hardly any known folder-gluer packers on the market that fit within the semi-automatic packing category, we based those “pros” on our semi-automatic packer: The Ergosa.

Shown below is a video of our semi-automatic packer, the Ergosa C, in action at a client's plant!

The video below demonstrates our Virtuo packer in action from different angles!

To make the comparison of the 4 categories of automation simpler, we’ve rated each category on a scale of 1-5 based on 5 key criteria.

Those 5 criteria were selected as the “key” based on our data which shows that these are the 5 main deciding factors that clients focus on when choosing a folder-gluer packer.

Since each category includes distinct solutions of varying levels (or ranges) of automation, most categories are also ranked in ranges. For example, 1-2, 2-4, 3-5 etc. 5 is the highest possible score for each category.

|

Manual |

Semi-Automated |

Automated |

Fully-Automated |

Rating (1-5) |

|

|

Price |

1-2 |

2-4 |

3-4 |

5 |

5 means most expensive |

|

Ergonomics |

1-2 |

2-4 |

4-5 |

N/A |

5 means most ergonomic |

|

Versatility |

3-5 |

3-5 |

2 |

1 |

5 means most versatile |

|

Performance |

1 |

2-4 |

4-5 |

4-5 |

5 means best performance |

|

Maintenance |

1-2 |

1-3 |

3-4 |

4-5 |

5 means needs most maintenance |

The price naturally follows the complexity. In other words, the further you go up towards full-automation, the more expensive the solution will be.

It is important for you to know that this comparison table does not reflect the fact that going from an auto process to a fully-auto might sometimes dramatically increase the cost.

The Manual packing process does not really offer much, if any, ergonomic gains.

All the box lifting and joint stress lead to injuries and is very commonly the primary concern in some of the projects we work on with our clients. Going the semi-automated path will significantly increase the ergonomics of your packing process.

"What about an auto process?"

Well since the work involved is usually not very labor-intensive, the auto process is the most ergonomic solution.

And in the fully-auto process, ergonomics is simply irrelevant! There are no humans involved. The machine does all the groundwork for you.

Collecting Tables (manual packing) and Semi-Auto packers are unquestionably the most versatile.

But their level of versatility depends on the technicalities of the process and the specifications of the machine offered by the folder-gluer packer manufacturer.

Some machines, for example, are just incapable of processing an under stacked shingle of 4-corners or crash-lock/auto-bottom boxes. On the other hand, others can process quite-literally anything you throw at them!

When it comes to auto and fully-auto packers, you inevitably sacrifice versatility for the sake of performance. It’s the natural trade-off of automation.

This is because those types of gluer packers require perfect control of your folder-gluer and are not tolerant of quality problems, adjustments, corrections or any modifications in the slightest.

A critical point to recognize is that a well-optimized semi-auto packer can easily reach the performance of an auto packer whilst maintaining the versatility of a semi-auto packer.

In other words, you cannot have the versatility of a semi-auto packer with an auto-packer, but you can reach the performance of an auto-packer with a semi-auto packer.

This explains why we dedicate a lot of time and R&D to the development of our semi-auto packer, the Ergosa.

As far as a fully-auto packer is concerned, it won’t always give you more performance and certainly not higher speed.

In fact, the ROI is completely focused on labor reduction in a fully-auto process.

The more you go up towards full-automation, the more you have to consider maintenance as a requirement to sustain, and consistently improve, your folder-gluer’s productivity.

All machines can and will eventually fail, breakdown or come across problems. That is common and okay. It is what a company can do to fix them, and maintain that, is what truly matters.

Having a proper maintenance plan in place is crucial to help you achieve the greatest payback out of your folder-gluer packer and avoid the top 4 problems that can happen while operating a packer.

That said, maintenance is also more expensive with auto and fully-auto packers and will require more time and technical/digital expertise.

IMPACK regional sales manager, Natascha Doeme and a client stand near the Ergosa box packing system with it’s accumulation conveyor, case ejection tilt tables and case management system

Ultimately, it all depends on what works best for your production, needs and company’s budget.

But I won’t leave you here.

To help you have a better idea of which folder-gluer packer is right for you, ask yourself the following 6 important questions and note down your answers:

Ready? Okay:

Your answers to those 6 questions will be your stepping stone to choosing the best folder-gluer packer for your production.

Do you have a better idea of what folder-gluer packer is best for your company?

Now that we have compared the 4 different types of folder-gluer packers, I would strongly recommend you to check out the following:

Compare Collecting Tables Vs. the Ergosa Packer to discover which is better for your company’s production.

Compare IMPACK’s 3 main folder-gluer packaging equipment in this side-by-side comparison: Ergosa Vs. Virtuo Vs. Everio - Which is the Best Folder-Gluer Packer?

Let’s address the elephant in the room that most packaging producers avoid talking about :

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

![Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]](https://impack.ca/hubfs/X21-011-1.png)

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?