What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

One of the first questions that every carton box manufacturer asks our company is: What folder-gluer packer is right for me?

And the second question always is: How much does it cost?

The truth is, most clients want an easy answer to this question but the reality is that there is no easy, or one answer, for every company.

Buying a folder-gluer packer is much like buying a pool or a house. With so many options available, the price can vary drastically not only from one option to another but also for every added feature.

The average price of a folder-gluer packer at IMPACK is between $7000 to $600,000+ CAD depending on its scope of automation. In this article + video , I will talk about what this scope means and what factors drive the cost up or down.

Note: All illustrated costs are in Canadian dollars (CAD). 1 CAD = $0.79 USD. Click on XE.com to open the currency convertor in a new tab that you can use as a reference while reading this article.

When someone asks us how much a folder-gluer packer costs, our answer is: It all depends on the scope of automation.

But what does “scope” mean?

The “scope” of automation refers to the level of automation that a folder-gluer packer offers.

And this “level” of automation depends on how much versatility, relative to performance, a folder-gluer packer is capable of offering.

“Versatility” signifies the degree of flexibility a folder-gluer packer can provide.

And “performance” is defined as a combination of the number of packing person(s) on the packing station vs. speed.

For example: If you keep the same speed on a Collecting Table (a packing help/aid to manual packing), but you reduce the number of packing persons from 2 packing persons to 1 packing person, then this results in a 2X performance gain.

If instead, you double the speed on that Collecting Table and reduce the number of packing persons from 2 to 1 (which is usually the best case scenario), then this results in a 4X performance gain.

We measure performance as a relative function to your existing packing operations.

For example: If an auto packer has 1.5X greater performance over a semi-auto packer, and that semi-auto packer has a 4X greater performance over a Collecting Table, then the auto packer has 6X greater performance than the Collecting Table.

Now that we’ve acknowledged how the cost of a folder-gluer packer is contingent on its scope (or level) of automation, let’s dive into the costs!

Different folder-gluer packer manufacturers offer distinct solutions with varying pricing ranges.

And those price ranges always depend on the scope of automation that each folder-gluer packer is offering.

At IMPACK, the average price of a folder-gluer packer is between $7000 to $600,000+ CAD depending on its scope of automation.

That is, folder-gluer packers fall into 4 categories of automation that define their scope: Manual packing, Semi-Automated packing, Automated packing and Fully-Automated packing.

It is noteworthy to mention that those 4 levels of automation are our own definitions and not dictionary definitions. They are always relative to what happens after the folder-gluer.

That said, they are informally accepted as the industry-standard, and most solutions on the market squarely fit within one of those 4 categories/levels of automation.

The “Collecting Table” is the most common machine that is used as a “packing help” or “packing aid” to the traditional manual packing process.

Collecting Tables are complementary packing solutions or peripheral devices that are added to a folder-gluer to better present/orient the boxes for the packing person(s), and hence facilitate an easier packing process. They generally have no automation and involve full manual work. In short, Collecting Tables serve as a packing help/aid to the traditional manual packing process.

Bobst’s Handypack GT, KBA Duran's Omega Pack Station and Tünkers' FAS 480 are some examples of the most widely present Collecting Tables in Western countries.

IMPACK's Collecting Table is called the "Packing Help Station."

IMPACK’s most basic Packing Help Station costs approximately $5000 CAD and it is simply a tilting table. It is noteworthy to mention that we offer several different versions of "Packing Help Stations" and this is our most basic version.

.webp?width=224&name=ezgif.com-gif-maker%20(62).webp)

If you add an accumulation conveyor to your tilting table, this will drive the cost up by an extra $15,000-$22,000 CAD. This means that you now have an accumulation conveyor + a tilting table as part of your “Packing Help Station” package.

-1.webp?width=624&name=ezgif.com-gif-maker%20(67)-1.webp)

If you add a box turner to your accumulation conveyor and tilting table, this will drive the cost up by an extra $5000-$37,000 CAD. This means that you now have an accumulation conveyor + a tilting table + a box turner as part of your “Packing Help Station” package.

A semi-automatic packer is a folder-gluer packer that offers a semi-automated packing process. It includes at least one automated function and the operator is still the key factor of the packing process, but with the help of at least one auto feature.

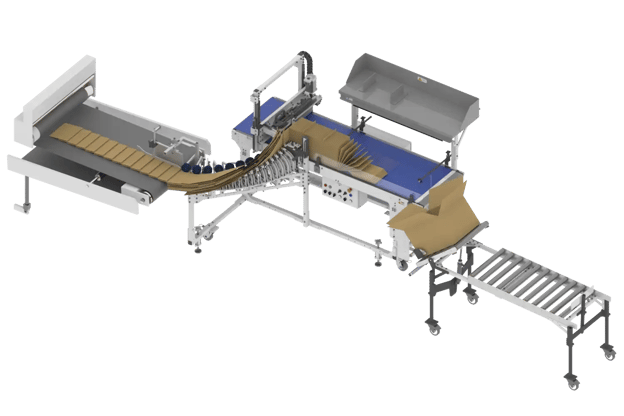

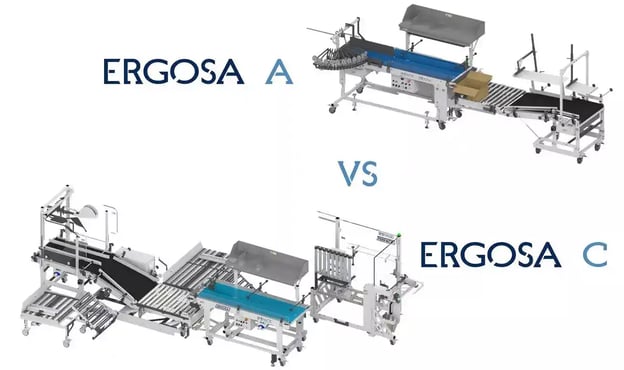

IMPACK’s semi-automatic packer is the "Ergosa" and it is one of the only semi-auto packers on the market. The Ergosa is semi-automatic because it includes an automated case management process.

The reality is that most carton box manufacturers are looking for a packer that achieves high performance but still meets extreme flexibility requirements.

And semi-auto packers fit the bill.

They are the perfect combination of high versatility and performance.

That is, they offer higher versatility than auto packers with the capability of achieving the same performance as an auto packer.

In other words, you cannot have the versatility of a semi-auto packer with an auto-packer, but you can reach the performance of an auto-packer with a semi-auto packer.

This unique combination of versatility and performance is what makes the Ergosa IMPACK’s most sold folder-gluer packer over the last decade.

IMPACK's semi-automatic packer, the Ergosa series, costs between $60,000 to $420,000+ CAD.

“Oh wow!! Why up to such a high number of $420,000+ CAD for a semi-auto packer?”

I will come back to this in a bit.

There’s always going to be a tradeoff between versatility and performance, and you have to evaluate which is more important for your company.

With semi-automatic packers, you will not be able to reach the highest possible speed as the setups will be manual, but you gain an unparalleled level of versatility and leverage high flexibility.

👉 More flexibility in the machine setup and box types means less automation.

👉 Less automation means lower cost of components and machine programming.

Now, let’s be a little more specific:

If you are mainly focusing on straight-line box performance, but you still want to run all other types of boxes, then your average semi-automatic folder-gluer packer could cost between $60,000 to $120,000 CAD.

Semi-auto packers are designed in a modular way so that you can add modules that allow you to increase your packing speed when it comes to more complex boxes. Some of those modules include:

These additional modules could altogether add an extra $10,000 to $80,000 CAD.

Unlike most companies, we do as much or as little as our clients need.

In other words, although our machines are standardized, we are not exclusive from a technical standpoint. We will customize and tailor solutions based on your production reality.

If there is an option/module that you will not need, why pay for it?

This is exactly the philosophy that our company, here at IMPACK, puts forward with our semi-automatic Ergosa packer.

Yes, we standardized our Ergosa series so that we have production volume and cost under control, but we are not exclusive from a technical standpoint.

The versatility of the Ergosa allows you to choose your options and modes, thus omitting any unnecessary options that you will never use.

This flexibility equates to less cost and less stress.

$420,000+ CAD – going back to this point.

If you’re running a lot of crash-lock/auto-bottom boxes and you want to produce them as fast as possible with the shortest setup time possible, then

We can confidently say that the MFA Module offers the easiest possible method on the market to invert batches of your crash-lock/auto-bottom boxes fully automated.

But to make this machine so simple to use, it took us over a decade of R&D. This is because the components and control unit must be very robustly built and long-lasting to ensure the machine’s reliability when running at very high speeds.

This combines our highly versatile and universal packer, the Ergosa C, with the MFA Module for fully automated inversion of batches which allows you to increase the production speed with 1 packing person by a factor of 1,5 to 2,5 and with many box shapes and sizes.

The Ergosa C packer paired with the MFA costs approximately between $280,000 to $350,000 CAD depending on the Ergosa C configuration.

The Ergosa C with the IN3 box turner and MFA Module combination is the only packer on the market that can run all types of folding carton boxes while allowing your folder-gluer to run at full speed for crash-lock/auto-bottom boxes.

And, this is how you end up at the high end of a semi-auto packer line with a cost of $420,000 CAD or more.

I would like to emphasize again that the box analysis of your folder-gluer production line must show that the MFA automatic batch inverter is worth the investment.

If there is no realistic forecasted ROI, then this solution won’t make sense, and we wouldn’t offer it to our clients even if they wanted it (it has happened before).

But if the ROI proves interesting, you will produce your crash-lock/auto-bottom boxes faster than pretty much everyone else in the industry!

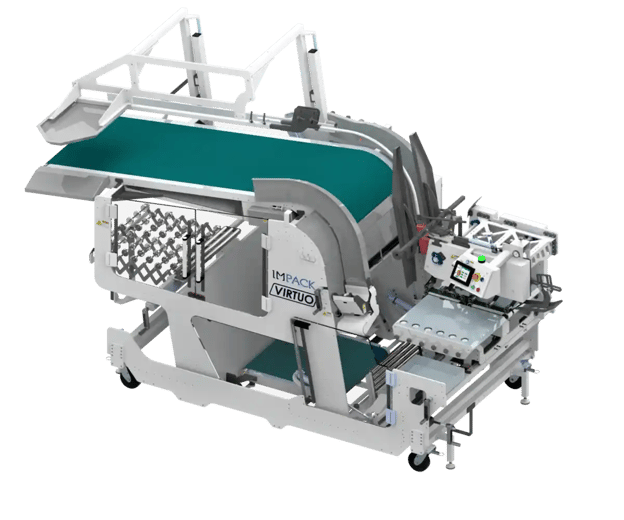

An automatic packer is where the machine becomes the key factor of the packing process and the operator is now limited to performing background tasks.

IMPACK’s automatic packer is the "Virtuo:" One of the only automatic packers on the market that can handle both carton and corrugated board.

The truth is, a lot of clients get very excited when companies propose and discuss automation and full automation solutions.

And it can be an easy sale for us, folder-gluer packer manufacturers, driven by the client’s pure temptation of having a robot doing the whole job, but that’s the perception in theory.

In practice, things are very different, and we want to make sure that you know this before you commit to any folder-gluer packer manufacturer.

You can add as many automatic features as you want to a semi-automatic packer, but as long as the operator is actively involved in the packing process, it’s still a semi-automated process.

It only becomes an automated process once the involvement of an operator is strictly limited to background tasks such as feeding the folder-gluer packer with empty cases or managing full cases.

Although their involvement is limited, humans are still part of the auto process.

IMPACK's automatic folder-gluer packer, the Virtuo, costs between $250,000 to $500,000+ CAD.

A fully-automatic packer involves the highest possible level of automation. It is when you’ve automated your entire packing process so that it is managed fully automatically without requiring the presence of any humans.

IMPACK’s fully-auto packer is the Virtuo paired with an Automatic case feeder: The "Virtuo +ACF"

Going fully-auto would mean automating what the human was previously doing in the auto process which is to place the empty cases into the machine.

In the fully-auto process, the machine can now place the empty cases by itself, then take the filled cases and seal them fully automatically.

Fully-automatic packers are the most expensive folder-gluer packers on the market because a human can always do things that a machine cannot, or can, but at a higher cost.

Full disclosure: Fully-auto packers are the easiest machines for us to sell because the box analysis process (which we always perform to ensure the correct packer fit for each client) is quickly performed and smoothly finalized.

How so?

This is because fully-auto packers involve astronomical numbers of boxes per production run which thereby means fewer setups, and usually, all the boxes are similar in type and size.

This leads to a far more standardized process and a standardized machine that aligns with the process.

Your product mix either fits the requirements of a fully-auto process or doesn’t. It’s a quick and seamless process.

But as you already know IMPACK by now, custom solutions are also possible for each and every client based on their unique and specific needs!

IMPACK's fully-automatic packer, the Virtuo +ACF, costs between $400,000-$600,000+ CAD.

If your product mix fits that of a fully-automatic packer, this means that you expect it to operate 24/7 at full speed without running into any problems.

To achieve that, all of the folder-gluer packer components must be designed to run non-stop because your production is entirely dependent on them performing flawlessly, around the clock, with no breaks and no downtime.

And that could come at an exponential cost.

You see — the more you try to automate a human, the more complex and costly it gets.

At the high end of the fully-automated process, the folder-gluer packer will have

Taking it a step further, you can increase the control system’s intelligence and capabilities to highly advanced automation levels that fit your production’s optimization system.

As mentioned earlier, we do offer custom solutions that are tailored to clients’ specific needs and their production realities but these requests are a factor that drives the cost upwards.

Fully-auto packers do not cost more because we charge higher rates. They cost more to buy because they cost more to make.

The cost of a folder-gluer packer all boils down to the complexity of the machine.

To be completely honest with you, our profit margin target is the same on all machines. We often even make a much lower profit margin on new high-end products such as the Automatic case feeder (ACF).

How Much A Folder-Gluer Packer Could Cost You 👇:

What really determines the final cost of a gluer packer is the options, modules and customizations that your specific production requires.

In a nutshell, the factors that drive the cost of a folder-gluer packer up or down are:

👉 The level of automation that the folder-gluer packer offers.

👉 Your need for versatility vs. performance.

👉 Your need for customization (and taking into consideration your floor space restrictions, whether you have special/complex box requirements, your product mix, production realities/constraints etc.).

We hope that this article helped give you a better understanding of how much a folder-gluer packer could cost you!

Do you have more questions that you need help answering before you pull the trigger on a folder-gluer packer?

Or maybe you want to see one of our packers LIVE in action first?

We are here to help!

Give us a call and let's talk about how we can help your company boost its folder-gluer productivity!

👉 Get a detailed breakdown of how much IMPACK's different machines cost by visiting "Pricing” on our website.

👉 Find out whether IMPACK offers discounts and what discounts you can qualify for by reading "Does IMPACK Offer Discounts? Here's Everything You Need to Know!"

👉 Discover “How Long is IMPACK's Delivery Time and What to Expect”

👉 Finally, save money on your IMPACK machine by avoiding the “7 Hidden Costs with Buying Packaging Equipment"

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

![Folder-Gluer Packers: What Level of Automation Is Right for You? [+VIDEO]](https://impack.ca/hubfs/X22-039-1.png)

Are you considering investing in a folder-gluer packer or folder-gluer stacker?

![What Folder-Gluer Packer Is Right For You? [+VIDEO]](https://impack.ca/hubfs/X21-004.png)

If you're thinking of getting a packing aid, semi-automating your packing or thrusting into full-automation, then you might be asking yourself: What...