How to Choose the Right Box Turner for Your Folder-Gluer Production

If you’re thinking of adding a box turner to your production, you’re probably asking yourself:

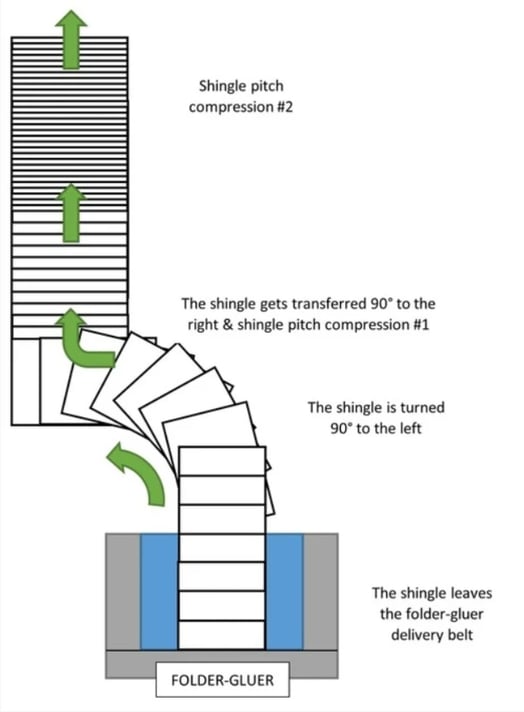

Carton boxes come out of a folder-gluer in a particular orientation that is determined by the gluing process.

Unfortunately, and in most cases, this orientation is not the same orientation at which you'd want to pack your boxes into cases based on your customer's request or based on best practice.

Therefore, 90% of the time, box manufacturers are forced to turn their boxes before packing them into cases.

The burden of turning boxes falls onto your packing staff.

This means:

👉 More work for your packing staff.

👉 Slower packing speeds and diminishing productivity.

👉 Less ergonomic workstations and greater repetitive strain injuries for your operators and packing staff.

What if I told you that you can easily solve this problem and save time and money?

What if I told you that you can fully automate the turning of your boxes so that you never have to worry about it ever again?

Welcome to the world of box turners.

Hi! My name is Francois Granger and I am an Area Sales Manager here at IMPACK.

Over the last 4 years, I have recommended, sold, and tested dozens of packaging equipment including Box Turners.

But, what is a box turner?

How does it work?

And, does your company really need a box turner?

In this article, I will cover everything you need to know about box turners, your available options, and how to choose the right box turner for your company.

Let’s dive in, shall we?

A box turner is a pre-packing device (a pre-packer) that individually turns each box in the shingle* exiting the folder-gluer to form a new shingle with the boxes presented/oriented in the desired direction.

Box turners can range from the most basic to the most advanced systems on the market depending on the technology used and the capabilities that these technologies offer.

Turning the boxes facilitates a case packing and(or) box bundling process since the boxes are presented/oriented in the correct direction so that they can be packed into cases or sent to be banded or strapped together.

Typically, straight line boxes must be turned prior to the case packing process. Therefore, having a box turner eliminates the need to manually turn your boxes before packing them into cases.

When it comes to 4/6 corner boxes, they are sometimes turned and other times left unturned. It all depends on your customer’s requested case packing configuration and the technology used for the case packing or box bundling.

As for crash-lock/auto-bottom boxes, they are most often inverted into batches to avoid wedge-shaped rows and to get a more compact case or bundle configuration. Hence, it is generally not necessary to turn crash-lock/auto-bottom boxes.

The purpose of a box turner is to allow you to rotate your boxes 90° to the left, 90° to the right, or straight through.

At IMPACK, we also offer box turners with 180° turning features, such as the IN180 Box Turner.

A box turner gives you the ability to control your box orientation so that you can meet each customer’s requested case packing configuration.

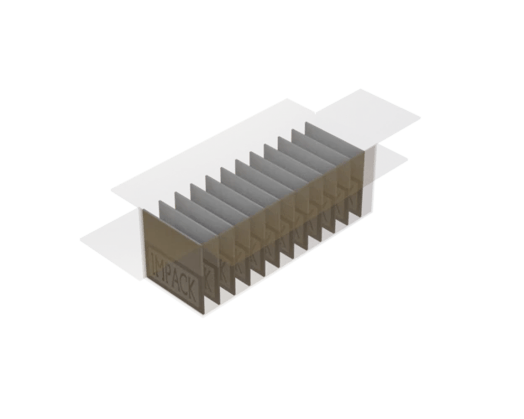

As you may already know, straight line boxes are typically packed with the glue-line laying horizontally in the case just like the orientation of the IMPACK logo shown in the image below.

This means that your boxes should be turned 90° before they are packed into the case.

If your boxes are not turned before they are packed into the case, they would come out standing up which would require your packing staff to manually turn them 90° and then pack them into the case.

Therefore, what a box turner really does is present/orient your boxes in the right direction before they enter the case packing or box bundling process so that your packing personnel do not need to turn the boxes manually.

This saves you time and money that is otherwise spent on asking your packing personnel to turn your boxes before packing them into cases or sending them for banding/strapping.

In sum, a box turner allows you to:

Automatically turn your boxes 90° to the left, 90° to the right, straight through, or 180°.

Have your packing personnel focus on the packing and not box turning.

Avoid repetitive movements which lead to constant wrist injuries.

Simplify the grabbing movement.

Save time and money during the packing process.

Improve the efficiency, ergonomy, and productivity of your packing process.

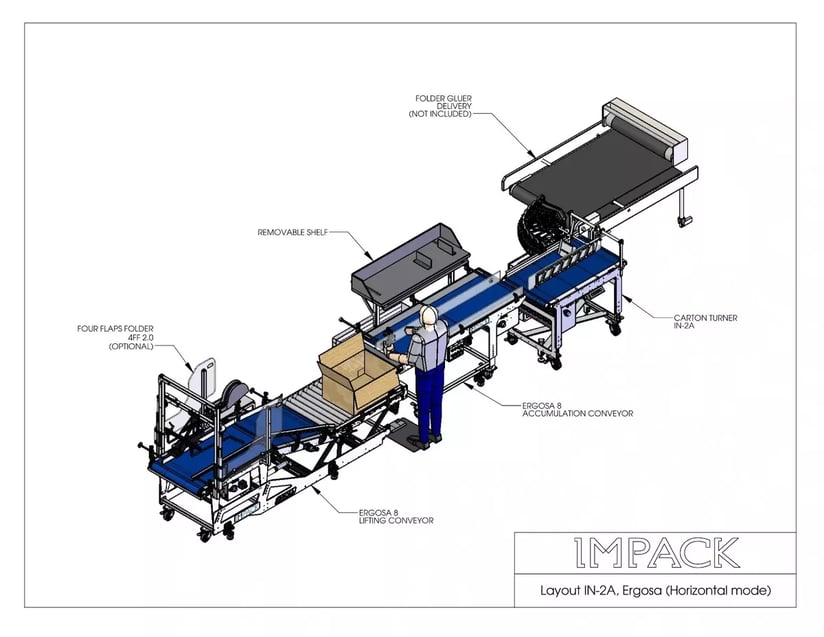

Being a pre-packer, a box turner is installed right after the folder-gluer and before the packer.

The image below shows where a pre-packer is located within the flow of folder-gluer packaging equipment.

Carton box and corrugated cardboard box manufacturers that own a folder-gluer packer or stacker need a box turner.

The only exception is if you own IMPACK’s Ergosa A packer which already includes an IN2 or INH box turner.

The best choice of a box turner always depends on your box sizes, product mix, format restrictions, and the amount of floor space you have available.

That is, they are entirely dependent on the type of folder-gluer packer or stacker you select.

🔍 Related: Ergosa Vs. Virtuo Vs. Everio: Which Folder-Gluer Packer/Stacker Should You Choose?

The working principles of a box turner vary based on the type of box turning technology used and the type of box turner product you choose.

There are 6 common box turning technologies on the market. Those are:

Basic Tooling on a Folder-Gluer

Helicoidal Turners

Turning Tables

Right Angle Transfer Conveyors

Shingle Turners

Combinations

I won't dive into these 6 most common box turning technologies here, but we have a complete article that compares "The Top 6 Box Turning Technologies on the Market" and walks you through how to know which box turning technology is right for your production.

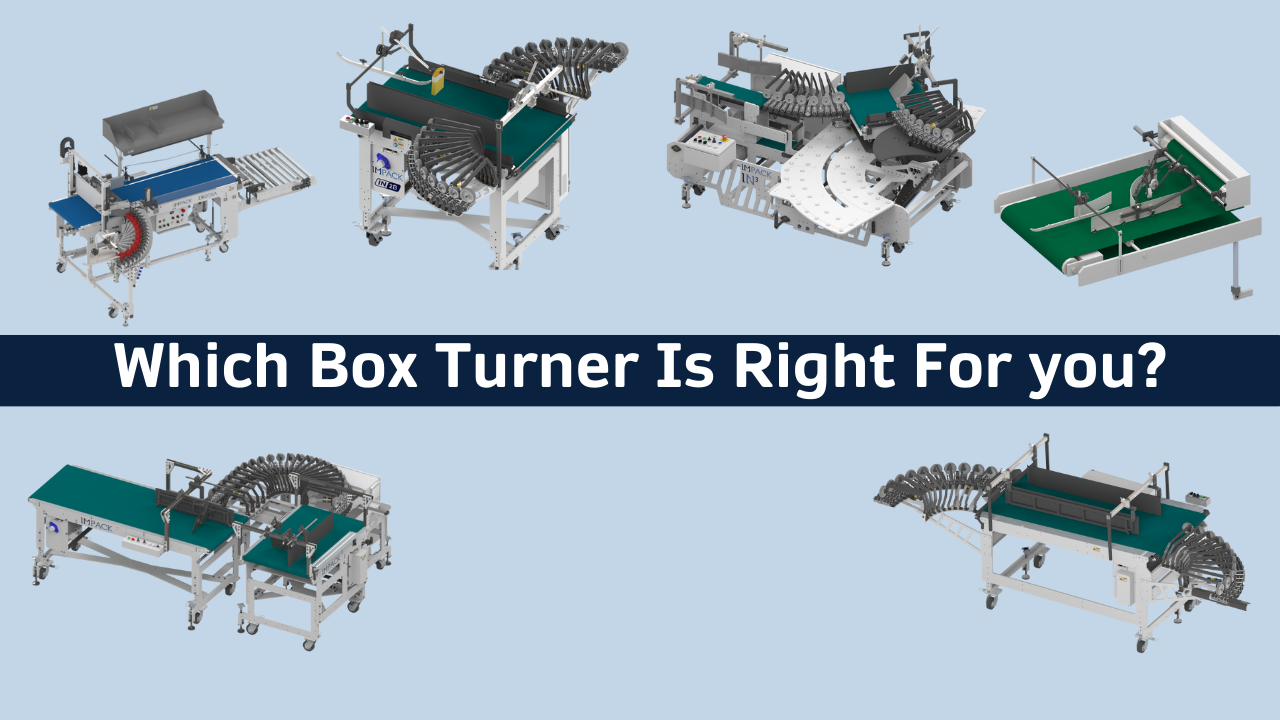

IMPACK’s 5 main box turners are:

Find out which box turner product is best fit for your company by reading "Comparing IMPACK's Box Turners: Which Is Best For Your Company?".

It all comes down to what your needs are.

Over 90% of carton box and corrugated cardboard manufacturers require a box turner to present/orient their boxes in the right direction before the boxes enter the case packing process.

If your boxes are not turned, they would come out standing up which would require your packing staff to manually turn them 90° before packing them into the case.

This wastes time and money on something that you can fully automate.

Your packing process is fully manual and you're not yet looking to automate your box turning process.

Efficiency and ergonomy improvements are not a priority for your company at this point in time.

Your packing configuration does not require you to re-orient your boxes after they exit the folder-gluer.

Your boxes must be turned before the case packing process (In most cases, it is mandatory to turn your boxes since they exit the gluer front-first and need to be packed on their folded edge).

You're interested in an IMPACK packer or stacker such as the Ergosa packer, Virtuo packer, or Everio stacker.

You already have a non-IMPACK packer or stacker and you need to turn your boxes to achieve a specific packing configuration.

You need to turn your box shingle to get it at a 90° angle or to return it in parallel with your folder-gluer (if there is not enough space at the end of your folder-gluer).

Here's the truth: Knowing which box turner is right for you is far from a simple task.

That said, in the next few sentences, I am going to give you all the info you need to make the smartest decision for your company.

First, you should know that choosing a box turner is not just about choosing the right product.

Choosing a box turner involves choosing the right box turning technology and the best fitting box turner product.

Start by comparing the different box turning technologies on the market by reading "The Top 6 Box Turning Technologies: Which Should You Choose?"

Next, compare the different box turner options in the article "Comparing IMPACK's Box Turners: Which Is Best For Your Company?"

Finally, find out which box turner is right for your company by reading "What Box Turner Is Right For You?"

If you’re thinking of adding a box turner to your production, you’re probably asking yourself:

If you own an Automatic packer such as Bobst's CartonPack, you may need to turn your boxes 180° before they can be packed into the case.

If you’re thinking of adding a box turner to your gluing line, you’re probably asking yourself: