What is the Virtuo Packer & What Companies Is It Best Suited For? [+VIDEO]

If you’re looking to improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach higher packing speeds, you’re probably...

![How Fast Can I Run With IMPACK’s Packers? [+VIDEO]](https://impack.ca/hubfs/X21-031.png)

You, and everyone else in the packaging industry, want to achieve the same common goal:

👉 Higher packing speeds.

Everyone wants that, but not everyone gets that.

And one of the top asked questions that we, folder-gluer packer manufacturers, get is 👇

“How fast can I run with your carton packer?”

We want to give you all the information you need to make a more educated decision before you ever have to speak to anyone.

And, with full transparency.

This article + VIDEO will explain to you how the packing speed of a packer is measured, what packing speeds you can expect from IMPACK’s packers, and how to boost your packing speeds.

The way packing speed is measured all depends on the thing we’re trying to measure.

If you’re working for a printing company, or if you’re in any way tied to the printing industry, you most certainly know that the speed of a printing press is measured in sheets per hour.

Likewise, the speed of a die cutter is measured in sheets per hour.

As for a folder-gluer, its speed is measured in boxes per hour.

Alternatively it can also be measured in linear speeds such as feet per minute or meters per minute.

But what about carton packers?

You’d expect to have the same “boxes per hour” measurement of packing speed as that of a folder-gluer. It only makes sense for it to be that way for packers so that you can gauge if a specific packer can go as fast as your folder-gluer. Unfortunately, it is not that straightforward.

There is an important distinction to be made between how the speed of a folder-gluer is measured versus how the speed of a packer is measured.

That is, the packing speed of a folder-gluer is measured as the number of boxes per unit of time: Boxes per hour.

In contrast, the packing speed of a packer or stacker is measured relative to the “container” in question.

More specifically, if you have a packer that packs boxes into cases (i.e. case packing), then the packer’s speed is measured in cases per minute where “cases” is the container in question.

Similarly, if you have a stacker that stacks boxes to be bundled/strapped together (i.e. box bundling) then the stacker’s speed is measured in bundles per minute where “bundles” is the “container” in question.

Now, if you have an inverter that inverts batches of boxes (i.e. batch inverting) then the inverter’s speed is measured in batches per minute where “batches” refers to the “container.”

You get the point!

In short, the important thing to acknowledge here is that the packing speed of packers, and stackers, is measured relative to the “container” that is filled with the boxes.

And, just like with a folder-gluer, the type of box (straight lines versus crash-lock/auto-bottoms) also affects the packing speed of a packer/stacker.

However, having only the box specification without the container configuration does not give you the complete picture. That would only allow you to have a broad, and inaccurate, representation of the packing speed.

To better understand this point, here is a concrete example:

Let’s assume that your packer is running at a speed of 3 cases per minute.

In the first scenario, let’s take a case configuration where you have a single row of 200 boxes.

The easiest way to understand the packing speed of a packer is by arriving at a measurement of packing speed that is the same as that of a folder-gluer i.e. boxes per hour.

The formula to calculate the packing speed of a packer in “boxes per hour” is the number of boxes x the number of cases per minute x 60 minutes.

In this specific example, 200 boxes x 3 cases/minute x 60 minutes = 36,000 boxes per hour.

Hence, a packer running at a speed of 3 cases per minute, with its case configuration being a single row of 200 boxes, has a packing speed of 36,000 boxes per hour.

Let’s now take a second scenario where your case configuration is a longer case that contains a single row of 350 boxes.

350 boxes x 3 cases/minute x 60 minutes = 63,000 boxes per hour.

This shows us that a packer running at a speed of 3 cases per minute, with its case configuration being a single row of 350 boxes, has a packing speed of 63,000 boxes per hour.

Therefore, it is easy to see that the case configuration has a significant impact on speed.

“But what is case configuration?”

I’m glad you asked! Case configuration refers to the way a case is configured to be packed with boxes. This includes the length of the case, the number of rows and(or) layers in a case, the size of the case, the gaps in the case, etc.

As a rule of thumb, the greater the length of the case, the greater the packing speed of a packer.

Likewise, when we’re talking about a stacker, the greater the number of bundles in a case, the greater the packing speed of a stacker.

But — that’s still not the full picture.

I assume that you’re reading this article because your goal is to ultimately reach the highest attainable packing speed; correct?

And how you go about doing that is what we’ll cover next. But first, let’s take a look at what packing speeds you can reach with IMPACK’s packers.

At IMPACK, we offer a wide range of folder-gluer packaging equipment with varying degrees, scopes, and levels of automation.

Our article “What’s the Difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers?” provides an in-depth explanation of the 4 different levels of automation that packers generally offer.

There are several factors that make those packers different from one another. One factor is speed. And for the sake of simplicity, we’re only going to focus on packing speed in this article.

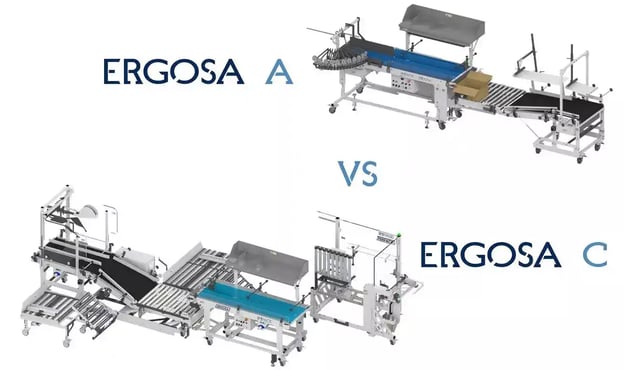

The Ergosa is a folder-gluer packer that optimizes your case packing process.

It can range from a manual to a semi-automated process depending on the packing modes and modules installed.

The vast majority of the Ergosas we produce include automated case management which makes them semi-automatic packers that offer a semi-automated packing process.

🔍 Related: What is an Ergosa Packer & How Can It Improve My Packing Process?

The Ergosa packer’s speed is directly dependent on the person operating the Ergosa. In other words, the Ergosa’s packing speed is contingent on the dexterity and skills of the operator running that Ergosa packer.

The learning process of an Ergosa is quite fast and the operator typically achieves high packing speeds just after a few days of training. But, we’re even more impressed by how fast the Ergosa can run when the operator has used the machine for a few months.

Additionally, other options such as 4 Flap Folders (4FF) and 4 Flap Holders (4FH) can help increase speeds further by smaller increments.

Under the Ergosa’s Horizontal Mode, you can expect a packing speed of 3 to 6 cases per minute.

Under the Ergosa’s Vertical Mode, you can expect a packing speed of 2 to 4 cases per minute.

Under the Ergosa’s Pick & Place (or Manual) Mode, you can expect a packing speed of 1 to 3 cases per minute (per operator/packing person).

With additional case management configurations, you can expect an additional 15% increase in packing speed compared to basic pick and place stations.

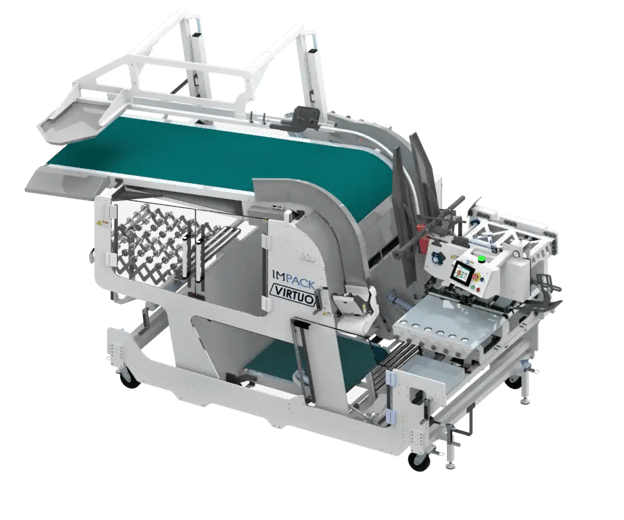

The Virtuo is a folder-gluer packer that optimizes your case packing process.

It can range from an automated to a fully-automated process.

In its basic and most common product offering, the Virtuo is an automatic packer that provides an automated packing process.

Adding the optional Auto Case Feeder (ACF) Module to the Virtuo packer is what pushes the Virtuo’s scope of automation into the fully automated category, hence making the Virtuo a fully automatic packer with a fully automated packing process.

The Virtuo packer’s speed is directly dependent on the box format i.e. the type, shape, size, dimensions, and weight of the boxes.

Whether the Virtuo is in the automatic or fully automatic configuration, the operator feeding the cases is never really a bottleneck since they are not packing boxes into cases.

Thus, the Virtuo can never be limited by the operator. All the operator does is place empty cases into the Virtuo so the packing speed of the Virtuo cannot be limited by the operator’s dexterity or skills.

Under the Virtuo packer, you can expect a packing speed of 3-8 cases per minute.

We consider the range of 6-8 cases per minute as one that requires a well-trained crew that has mastered its folding-gluing process and fine-tuned the setup of the Virtuo to its most performant level.

🔍 Related: Top 5 Ways to Improve Your Folder-Gluer’s Productivity with Zero Investment

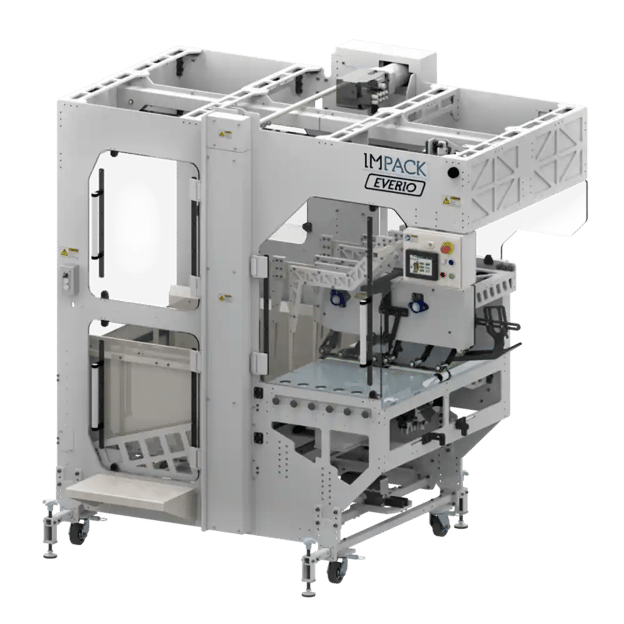

The Everio is a folder-gluer stacker that meets bundling needs. Bundling is the process of stacking boxes that are exiting the folder-gluer in a shingled stream and building a bundle which is then either banded or strapped together.

It can range from a semi-automated to a fully-automated process.

Note that the Everio is a stacker and not a packer.

In most cases, the Everio stacker is a fully automatic machine offering a fully automated packing process.

The Everio stacker’s speed is directly dependent on the box dimension. That is to say, a small box can certainly run faster than a larger box. Therefore, the smaller the box, the greater the packing speed on an Everio.

Under the Everio stacker, you can expect a packing speed of 10-20 bundles per minute.

We consider the range of 15-20 bundles per minute as one that requires you to fine-tune your equipment to a point that it achieves a steady and consistent output. That said, we rarely see the Everio running faster than 15 bundles per minute given the fact that the folder-gluer itself cannot reach that speed most of the time.

The only way for you to become the top speed producer in your industry, and dominate your market, is by influencing the parameters that affect your packing speed.

There are 2 key parameters that you can manipulate to your advantage:

Your case length.

The number of rows and layers in each case.

Case length is one of the most important variables that influences your packer’s packing speed.

Optimizing your case length simply means having a longer case that allows for more boxes per each case.

More boxes per case implies a greater total number of boxes processed per hour on the folder-gluer without increasing the total number of cases per minute. This results in an overall greater net packing speed on your packer.

Knowing that, increasing your case length infinitely is not realistic or feasible. Your case’s length must still be manageable by your operator since the operator can only manipulate so many boxes with their own hands.

Increasing your case’s length allows you to increase the number of boxes per each case, but there comes a point where the number of rows are too many for an operator to handle.

“How many boxes is too many?!”

Well, that’s subjective. It all boils down to the dexterity and skills of your operator.

For an Ergosa packer, the optimal case length varies from 450mm to 600mm.

We always recommend to our clients a maximum case length of 500mm under the Ergosa’s Vertical Mode.

For a Virtuo packer, the optimal case length varies based on the overall weight of the case.

Case length optimization on a Virtuo packer is more straightforward since it’s limited to a single row and single layer. Usually, the longer the case length, the better!

The number of rows and layers of boxes you pack into each case also has an impact on your packer’s packing speed.

The Ergosa packer offers multi-row, multi-layer packing. Hence, increasing the number of rows and(or) layers of boxes that you pack into each case increases your packing speed on the Ergosa packer.

Just like increasing the case length, adding more rows and(or) layers of boxes into each case leads to a greater number of boxes per hour processed on the folder-gluer and an overall less number of cases that you would have to manage.

Fewer cases being managed means that you open fewer cases, prepare fewer cases for filling, prepare fewer cases for ejection, and ultimately, eject fewer cases.

Then again, there’s always a balance to reach as too many rows or layers becomes far more difficult to manage.

In contrast, the Virtuo packer is limited to 1 row-1 layer packing. Thus,increasing the number of rows or layers to increase your packing speed is not possible on a Virtuo packer.

Step #1: Increase your case length to the longest manageable case length.

The longer the case, the greater the number of boxes per case and the less the number of cases you manage. This equates to a greater overall number of boxes per hour processed on your folder-gluer and hence a greater net packing speed on your packer.

Note: Your case length and weight must still be within a scope that’s manageable by your operator.

Step #2: Next, increase the number of rows and(or) layers of boxes packed into each case.

The greater the number of rows and(or) layers of boxes packed into each case, the less the number of cases you manage. This, again, equates to a greater overall number of boxes per hour processed on your folder-gluer and a greater net packing speed on your packer/stacker.

The speed gain in step #2 is derived from the time saved to prepare more empty cases. Admittedly, this step gives less improvement in packing speed compared to increasing your case length.

The “time saved” varies from 3-10 seconds per case and is completely dependent on the operator’s dexterity and skills. Having to prepare only one case for multiple rows and(or) layers of boxes contributes to a better overall packing speed.

For example, if you effectively reduce the packing speed from 4 cases per minute to 2.5 cases per minute. But putting two layers into one case instead of one, you effectively increase the boxes per hour speed by 25%.

In sum, the more boxes you fit in a case, the faster you can run.

The table below illustrates, with full disclosure, the average and maximum packing speeds we’ve seen our packers running at our clients’ production sites. Not at IMPACK’s manufacturing plant but during real-life utilization of IMPACK’s packers by real clients.

It is interesting to note that the average speed is the point at which the folder-gluer becomes the bottleneck.

In other words, most clients that achieve average speeds and are unable to go faster aren’t limited by the fact that their carton packer cannot go faster. The packer can run faster but their folder-gluer has hit its maximum possible speed and it has now bottlenecked the packer.

🔍 Related: Are you at a point where your folder-gluer has hit its maximum speed and you’re not sure what to do next? Learn about the Top 7 Ways to Improve Your Folder-Gluer’s Productivity & Reach Higher Packing Speeds.

|

Average Speed |

Maximum Speed |

Real Examples from IMPACK’s Current Clients |

|

|

Virtuo Packer |

3 cases per min |

8 cases per min |

60,000 boxes per hour |

|

Ergosa Packer in Horizontal Mode |

3 cases per min |

6 cases per min |

100,000 boxes per hour |

|

Ergosa Packer in Vertical Mode |

2 cases per min |

4 cases per min |

48,000 boxes per hour (crash lock/auto-bottom boxes with the MFA Batch Inverter). |

|

Ergosa Packer in Pick & Place Mode |

1 case per min |

3 cases per min |

Depends on the dexterity and skills of the operator(s) |

|

Everio Stacker |

12 bundles per min |

20 bundles per min |

Depends on boxes per bundles |

As we have seen, there is an important distinction between how the packing speed of a folder-gluer is measured versus how the packing speed of a packer/stacker is measured.

Before you decide on a new packer, whether it be from IMPACK or another manufacturer, there are a few important takeaways I want to leave you with:

→ Remember that the packing speed of a packer/stacker depends on 2 main variables: Your case length and the number of rows and(or) layers of boxes you’re packing into each case.

→ With the Ergosa packer, increasing your case length and the number of rows and(or) layers of boxes you’re packing into each case will lead to higher packing speeds.

Because the Ergosa offers multiple packing modes and various configuration options, there are many ways to optimize your packing speed on an Ergosa packer.

→ With the Virtuo packer, increasing your case length will lead to higher packing speeds .

In addition, the Virtuo packer is limited to single-row, single-layer packing which means that you cannot increase your packing speed by increasing the number of rows or layers on a Virtuo packer.

→ Given that the Ergosa packer is a very versatile and modular machine with many possible configurations and optimizations, it requires more data collection and analysis from your production to ensure that it is best optimized for your production.

→ Given that the Virtuo packer is a more complex machine with strict requirements, it demands a clearly defined scope, a perfectly dedicated production, and has zero margin for error.

This makes projects involving the Virtuo packer much more straightforward. Either it works for your production or doesn’t. The maximum speed is also usually easy to foresee.

Now that we’ve broken down how packing speeds are calculated and the different packing speeds offered by IMPACK’s packers, your next steps would be to:

![What is the Virtuo Packer & What Companies Is It Best Suited For? [+VIDEO]](https://impack.ca/hubfs/X21-045-1.png)

If you’re looking to improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach higher packing speeds, you’re probably...

Are you struggling to improve your folder-gluer's productivity?

You and your competitors have 1 common goal: