How to Maximize Your Productivity with the Ergosa’s Horizontal Mode

You’ve ordered an IMPACK Ergosa packer.

9 min read

Maxime Jacques

:

August 24, 2021

Maxime Jacques

:

August 24, 2021

.jpg)

Your new Ergosa packer has been delivered, installed, and started.

Your operators are now well-trained on the Ergosa and you’re starting to see your productivity rise.

You’re now considering retrofitting the Vertical Mode to your Ergosa C, or you already have the Vertical Mode, and want to learn how to push your Ergosa’s productivity to its maximum potential.

You’re asking yourself 👇:

“Can I manipulate the same parameters as with the Horizontal Mode to maximize my productivity under the Vertical Mode?”

“Are there any other factors to be taken into account?”

“Can I expect the same productivity gains as with the Horizontal Mode?!”

Every packing mode of the Ergosa is designed to serve a different purpose. And, therefore, each packing mode has its own parameters and characteristics.

Some optimizations are transferable from one mode to another; others are not so much or are transferable but in a more limited fashion.

From wiring to startup, programming to testing, and installation to sales, I have worked on more Ergosa packers than my fingers can count in the last 10 years.

This article will outline to you how to maximize your productivity with the Ergosa’s Vertical Mode.

By the end of this article, you’ll be fully equipped to unleash your Ergosa’s full potential.

In the article “How to Reach Maximum Productivity with the Ergosa’s Horizontal Mode?,” we talked about how you can substantially increase your Ergosa’s productivity with the Horizontal Mode if you know what parameters to influence.

The same idea applies to the Ergosa’s Vertical Mode, but the question here is:

Are those parameters the same?

The answer is yes and no. Some optimizations are transferable from one mode to another while others are not transferable or are transferable but in a more limited way.

Let’s start by defining the formula of packing speed under the Vertical Mode.

The mathematical equation of the packing speed is simply the formula used to calculate the packing speed.

You will see that the mathematical equation of the packing speed under the Vertical Mode is not very different from the mathematical equation of the packing speed under the Horizontal Mode.

Just like we did under the Ergosa’s Horizontal Mode, I will breakdown the packing process into its 3 main stages:

Step #3 — Packing (P) also includes all the control operations, labeling, etc. The operator will repeat Step #3 — Packing (P) as many times as there are rows in the case.

The Vertical Mode allows 1 or 2 rows and 1 layer (2 layers is also possible under certain conditions).

Once the row of boxes has been packed into the case, the Ergosa C will

For each of these 3 steps outlined above that constitute the packing process, we can define the average time needed for the operator to perform the action.

After many years of repeating this process, constant testing, and regular validations from our clients and experts, here is the predicted average time needed for the operator to perform each step:

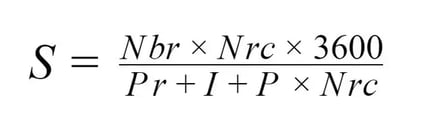

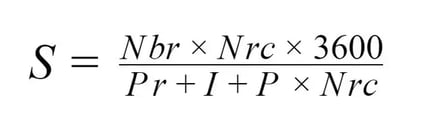

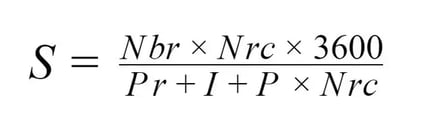

By breaking down the packing process into its 3 main steps, we can define the packing speed with the following formula:

Where :

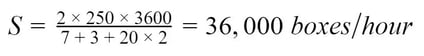

For example, if the case consists of 2 rows per case and 250 boxes per row, the packing speed will be:

🔍 Related: What Packing Speeds Can You Reach with IMPACK’s Packers?

Now that we’ve broken down the formula of packing speed and how it is derived, let’s take a closer look at the parameters of this equation and how each parameter affects the packing speed.

We defined the formula of packing speed under the Ergosa's Vertical Mode as:

For the speed (S) to be as high as possible in value, the numerator (Nbr x Nrc x 3600) must be as high as possible and the denominator (Pr + I + P x Nrc) must be as low as possible.

Of these parameters, 3 have a significant impact on the speed (S), and thus the productivity, of the Ergosa in Vertical Mode. These 3 parameters are bolded below:

Those 3 parameters are the same parameters that you can take advantage of to influence the productivity of the Ergosa in Horizontal Mode.

However, and unlike with the Ergosa’s Horizontal Mode, there is one specific parameter that you only have limited control over when using the Ergosa in Vertical Mode.

This parameter is the Nrc = Number of rows per case.

Why so?!

This is because the Ergosa’s Vertical Mode allows 1 or 2 rows per case and not more.

As far as the other 2 parameters are concerned (3600 = Number of seconds per hour and I = Insertion time), you cannot influence them simply because there will always be 3600 seconds in an hour and the insertion time (I) of a case in the Ergosa's PerPack Case Holder System cannot be reduced.

An operator that is efficient in their work and has a good organization around their workstation would possibly gain 1 second at most. Hence, the Insertion time (I) is practically invariable.

Alright. Now that we talked about the parameters you cannot influence, let’s divert our attention to what’s important:

The 3 parameters that you can fully influence and the 1 parameter that you have limited control over when it comes to the Ergosa’s Vertical Mode.

The 3 parameters that you can fully influence are: 1) Nbr = Number of boxes per row, 3) Pr = Preparation time, and 4) P = Packing time per row.

The 1 parameter that you have limited influence over is: The Nrc = Number of rows per case.

The greater the Nbr = Number of boxes per row, the greater your packing speed.

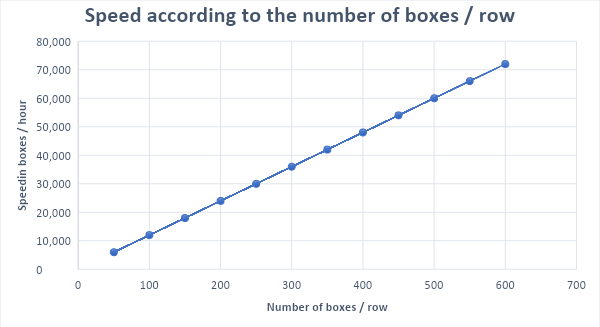

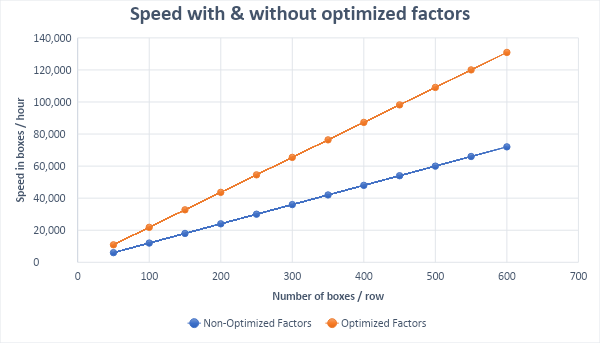

The chart below shows a visual representation of how increasing the number of boxes per row results in higher packing speeds (Nrc = 1, Pr = 7, I = 3, P = 20).

“Okay, what’s the ideal number of boxes per row?”

Unlike the Horizontal Mode, when it comes to defining the number of boxes per row with the Vertical Mode, you do not have to take into account the weight of the row.

This is because with the Horizontal Mode the operator has to slide the row of boxes into the case, but with the Vertical Mode you have a "pneumatic assisted pusher" where you can adjust the pressure of the "assisted push" according to your needs.

If the row is heavier, you can increase pressure of the assisted push to make the packing process easier.

If the row is lighter, you can reduce the pressure of the assisted push.

Thus, the weight of the row is not a factor that influences the ideal number of boxes per row under the Ergosa's Vertical Mode given that the pusher benefits from the pneumatic assistance.

In sum, to maximize your Ergosa’s productivity, increase your number of boxes per row to the largest amount possible.

As we have mentioned earlier, this is the parameter that you only have limited control over when using the Ergosa’s Vertical Mode.

We also saw in the article “How to Reach Maximum Productivity with the Ergosa’s Horizontal Mode? that the Nrc = Number of rows per case is a complex factor to determine since it is present in both the numerator and denominator of the formula of packing speed.

Therefore, we have to find a point of equilibrium that balances these 2 phenomena.

We determined under the Horizontal Mode that the ideal Nrc = Number of rows per case is 4, which is more than what the Vertical Mode allows.

For the Vertical Mode, the largest possible number of rows is 2 rows per case.

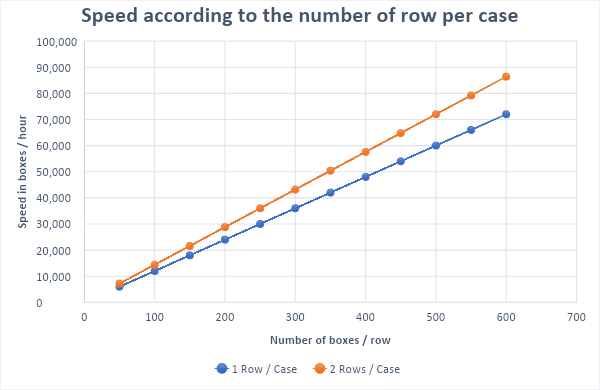

The graph below shows how the packing speed changes when the Nbr = Number of boxes per row changes and when the Nrc = Number of rows per case is 1 row per case versus when it is 2 rows per case (Pr = 7, I = 3, P = 20).

As you can see from the graph, the gain in packing speed from 1 row per case to 2 rows per case is 20%.

“What’s the ideal number of rows per case?”

From the graph, there is little doubt that you would want to have 2 rows per case.

For very large boxes, you will have to ensure 2 things: 1) That the specifications of the Vertical Mode allow for those very large boxes and 2) That the total weight of the case is not too high for your palletization operator to handle if you don’t have a palletization robot.

In sum, to maximize your Ergosa’s productivity, increase your number of rows per case to 2 rows per case while taking into consideration the specifications of the Vertical Mode and the total weight of the case according to your local rules.

The Pr = Preparation time is the time it takes an operator to prepare each empty case so that it can be packed with the boxes.

The Pr’s value is either 0 or 7 seconds.

If the operator in charge of packing boxes into cases is also responsible for preparing empty cases, then the Pr’s value is 7 seconds.

If your packing station is equipped with a case erector or you have a separate operator in charge of preparing empty cases, then the Pr’s value is 0 seconds.

Having a case erector influences the impact the Nbr = Number of boxes per row has on the speed (S).

To better understand how a case erector influences your speed (S), we put 2 examples that show what happens to the speed (S) if you do not have a case erector versus if you do have a case erector.

Let’s take an example of 2 situations where 1) you do not have a case erector versus 2) you do have a case erector (Nbr = 300, Nrc = 1, I = 3 & P = 20):

The gain in packing speed with a case erector is about ±30% higher than without a case erector.

It is obvious that having a case erector increases the speed considerably versus when not having a case erector.

The P = Packing time per row refers to the time needed to pack each row of boxes into the case.

The P = Packing time per row depends on two things: First, the packing person’s (or operator’s) level of involvement in the packing, and second, the number of operations this packing person/operator has to perform.

If the packing person has to also carry out controls, label the boxes, take samples for quality control, etc. in addition to packing rows into cases, then the P = Packing time per row can vary from 15 to 20 seconds per row (but we’ve seen well-organized operators in this same situation capable of performing the operation in around 10 seconds only).

In-line automatic quality control systems, such as those recommended for the glue control unit, will allow you to automate these quality-control checks and thus reduce the number of actions that the packing person/operator(s) will have to perform.

Finally, the organization of your packing station plays a fundamental role.

If everything is adapted such that it makes the workload simple and consistent for your packing staff, then your packing person/operator(s) will be able to reduce their P = Packing time.

A motivated operator with a well-organized workstation and a gluing line that’s equipped with a quality control system, automatic labeler, etc. will allow your operator to fully concentrate on the packing process and realize significant reductions in the P = Packing time.

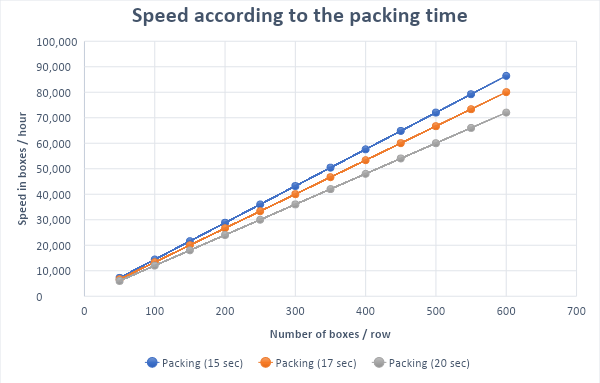

The following graph shows the gain in packing speed between a P = Packing time of 15 seconds versus 17 seconds versus 20 seconds.

You should know that the boxes themselves can also influence the P = Packing time.

That is to say, depending on their shape, size, paint, varnish used, it can make the operation simpler or more challenging and therefore affects the P = Packing time.

As we have seen, there is so much you can do to dramatically increase your Ergosa’s productivity.

For some parameters, you can take action right away.

For others, it will be necessary to educate your sales team on how to properly define new contracts.

And for the last parameter (P = Packing time per row), adding in-line automatic quality control systems, an automatic labeler, etc. will allow you to realize substantial profit gains.

In case you still have any doubts, the graph below demonstrates the gain between “standard” parameters (Nrc = 1, I = 3, P = 20, Pr = 7) and “optimized” parameters (Nrc = 2, I = 3, P = 15, Pr = 0).

As the graph shows, you can achieve an 82% speed gain by optimizing those parameters we discussed: Parameters that you have direct control over.

Higher packing speeds mean greater productivity which will allow you to offer better prices, become more competitive, and conquer new markets.

In sum, there are 3 parameters you can manipulate to your advantage under the Ergosa’s Vertical Mode:

Become the top speed producer in your industry by mastering those 3 parameters.

Your Next Steps:

👉 How to Maximize Your Productivity with the Ergosa’s Horizontal Mode

👉 How to Maximize Your Productivity with the Ergosa’s Pick & Place Mode

👉 How Fast Can I Run With IMPACK’s Packers?

Got more questions that you want answers for?

Get in touch with an IMPACK Expert for help! They can answer all your questions and determine the best solutions for the problems you’re experiencing!

.jpg)

You’ve ordered an IMPACK Ergosa packer.

👉 You’re thinking of purchasing an Ergosa packer to maximize your folder-gluer’s productivity, but you want to be 100% certain that you’re making...

.jpg)

Your new Ergosa packer has been installed and started at your facility.