How Do Understack Shingles Affect Your Choice of a Packing System?

So, you’re thinking of adding a packer or stacker to your folder-gluer.

2 min read

Stefan Badertscher

:

March 2, 2023

Stefan Badertscher

:

March 2, 2023

Manual packing is the traditional packing method used for decades where the whole packing process is done manually.

And the packing system most commonly used in the manual category is a Collecting Table.

Collecting Tables are non-automated packers that serve as a packing aid for your packing person(s) handling the packing and case handling the job at the end of your folder gluer line.

In this article, we will break down what manual packing is and then explore its advantages and disadvantages.

At IMPACK packaging, you can find our Collecting Table under “Packing Help Stations.”

Manual packing is the manual process of packing your folded and glued boxes and placing them into cases, it is an entirely manual packing system.

Manual packing systems often require multiple operators to pack directly at the end of the folder-gluer's compression belt.

This process can be somewhat crowded due to the need for one or two packing persons as well as someone who takes care of the casing process.

In addition, most Collecting Tables are made of wood or stainless steel and have “tilting holders/stands” used to tilt the cases at an angle to facilitate the casing.

The most popular Collecting Tables on the market have a right angle on the left or right with a box turning feature and some form of tilting table.

Nevertheless, manual packing is the lowest level of automation and the packing systems that fall into this category, such as Impack's Packing Help Station, involve full manual work without any automation in the packing or casing process.

Now that you understand the manual packing process of Collecting Tables, let’s explore the advantages and disadvantages of manual packing.

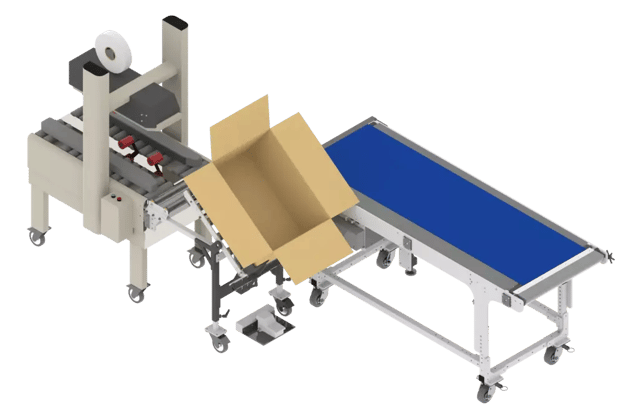

Impack Packaging Packing Help Station 1.0

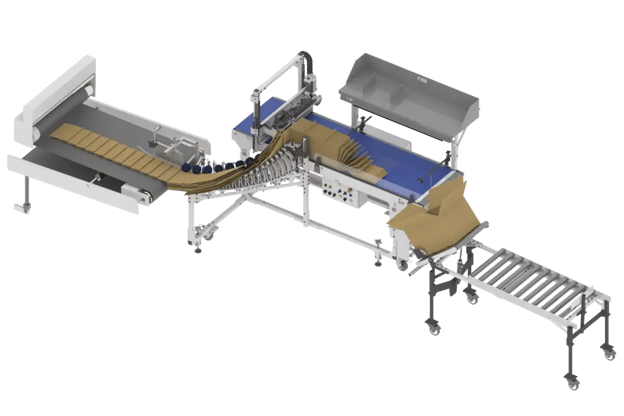

Impack Packaging Packing Help Station 2.0

Although a manual packing process under Collecting Tables presents many advantages, such as low cost, simplicity, and movability, semi-automatic or automatic folder-gluer packers may be the best solution for you.

If you want to learn more about the packing options on the market, read the following articles to learn everything you need.

How Much Does a Folder-Gluer Packer Cost?

Automatic Vs. Fully-Automatic Packers: Which Should You Choose?

So, you’re thinking of adding a packer or stacker to your folder-gluer.

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

You and your competitors have 1 common goal: