Can IMPACK’s Machines Damage My Boxes?

One of the Top Questions we get asked here at IMPACK is: 👉 “Will your machine damage or mark my boxes?” The short answer is no.

4 min read

Mathieu Tremblay

:

September 21, 2021

Mathieu Tremblay

:

September 21, 2021

Automated folder-gluer peripherals help finishing lines reach maximum capacity.

Despite efforts to increase finishing line productivity, folder-gluer speed is impacted by one key bottleneck: even a full team at the packing station can't keep pace with the potential speed of the folder-gluer. When IMPACK was founded 20 years ago our mission was to help packaging producers solve this number one process limitation. Since then our line-up of folder-gluer peripheral automation solutions has expanded to solve other speed and efficiency limiters.

Hello, I'm Mathieu Trembly, Deputy General Manager at IMPACK.

At IMPACK, we design, manufacture, and install Semi-Automatic, Automatic, and Fully-Automatic folder-gluer packing and stacking equipment. We also offer an revolutionary in-line window patcher that allows you to add functionality to your existing folder-gluer line.

In this article I will help you determine which solution fits your unique situation and solve your bottlenecks.

Folder-gluer peripherals includes:

At IMPACK, we offer solutions in eight of these categories with varying degrees of automation.

Those levels of automation are divided into 4 categories:

Semi-Automated

Automated

Fully-Automated

The Ergosa Universal Packer, the Virtuo Packer and the Evario Stacker replace slow laborious manual packing.

If you do short-runs of many different box types the Ergosa Universal Packing and Stacking Solution is an excellent way to increase your folder-gluer speed, boost productivity and provide a more ergonomic packing station for your packing personnel.

If you do longer runs of a few box types the Virtuo Automatic Packing Solution or the Everio Automatic Stacking Solution will allow you to reach maximum speed, productivity and profits.

If you do a mix of both short and long runs, and have more than one folder-gluer you can:

Let's compare the features and functionality of our main productivity solutions.

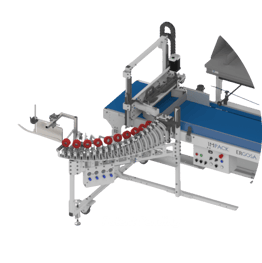

The Ergosa Univeral Packing Solution makes multi-row, multi-layer packing more efficient for all box types. It is a modular system that can be configured to fit your product mix. You can configure a system that includes only the modules you need for your production. Due to its modularity you can get started in the Ergosa System with a base configuration and add more modules later as your production evolves or your budget for investments increases. It is fully compatible with folding carton and corrugated box types.

The Ergosa Modular System features packing modes optimized to specific box types. When switching between box types, it only takes 3-7 minutes to change between modes.

Horizontal Packing Mode

Small to medium straight-line boxes & small 4/6 corner boxes

Vertical Packing Mode

Medium to large straight-line & 4/6 corner boxes

Dual Hand Packing Mode

Complex boxes types

IMPACK offers optional tooling to accommodate trays for small boxes i.e., pharma and cosmetic boxes. The horizontal mode features a utility shelf for QA samples, case dividers and tools. The Automatic Case Management System manages case ejection, folds flaps and directs filled cases to a case sealer. Paired with the accumulation conveyor module, the patented INH Box Turner reorients boxes and creates a very dense shingle while maintaining the kicker count.

See the Ergosa in action by visiting the product page.

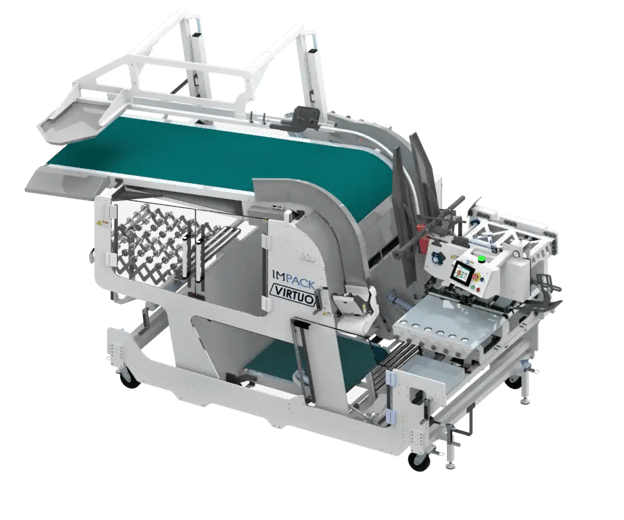

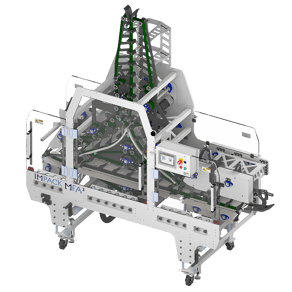

The Virtuo Packer is one of the most compact automatic packers and the only packer on the market that can handle both carton and corrugated board.

While we refer to the Virtuo as an automatic packing solution, adding the optional Auto Case Feeder (ACF) Module allows you to fully automate the process.

🔍 Find out more about how we define levels of automation at IMPACK.

A high performance automatic packer and the most compact auto packer on the market

Compatible with folding carton and corrugated board

Compatible with all folder-gluer models

Runs medium to very large box formats

Offers one-row, one-layer packing capabilities

Short setup time - less than 10 minutes

Speed: Up to 8 cases per minute

High-precision laser counter

Includes a case loader (conveyor that feeds the cases into vertical packing position)

Includes an intuitive touchscreen interface

🔍 Learn more about “The Virtuo Packer & How Can It Improve Your Packing Process?”

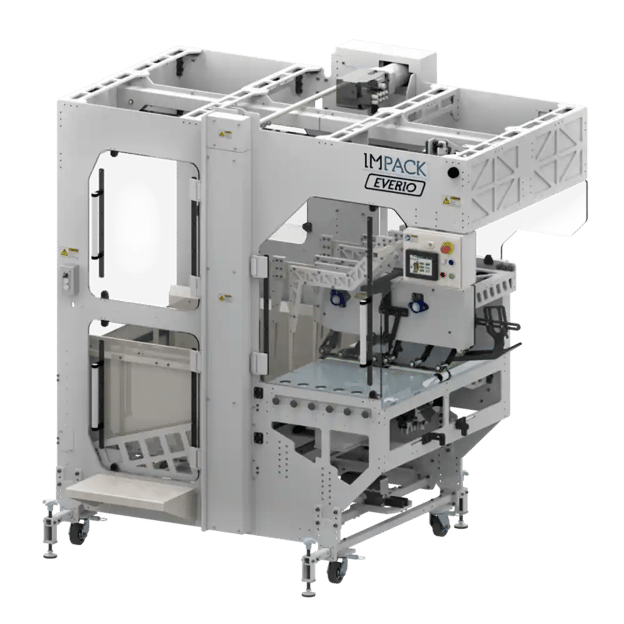

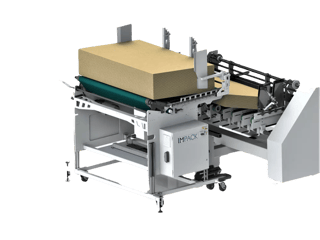

The Everio Stacker stacks and bundles boxes before sending them to a separate banding machine(ATS, Mosca or SMB).

To help you differentiate, the Ergosa and Virtuo are finishing line packers that facilitate the case packing process. The Everio is a folder-gluer stacker that meets your bundling needs.

The Everio stacker takes a shingled stream of folded cartons, accumulates the boxes vertically, counts and bundles batches and then sends them for banding or strapping.

The Everio does not do case packing.

Compatible with all folder-gluer models

Fully automatic stacker with a super compact footprint

Compatible with carton and corrugated board

Runs medium to large box formats

Runs straight lines, 4/6 corners, and crash-lock/auto-bottoms

Compatible with many brands of automatic banding machines, such as ATS, Mosca, or SMB/Signode

Speed: Up to 20 stacks a minute

High-precision laser counter

Includes a touchscreen interface

🔍 Learn more about “What is an Everio Stacker & How Can It Improve Your Packing Process?”

All folder-gluer packers and stackers require a box turner.

The box turner turns the shingle of boxes as it exits the folder-gluer so that they enter the case(or banding machine) in the right direction. Our Expert advisors will help you select the box turner that fits the needs of your finishing line.

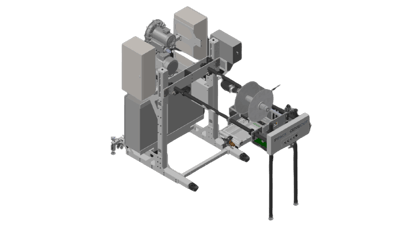

Our MFA counts and inverts batches of crash-lock folding carton boxes allowing you to maximize the space in a case.

Our Prefio pre-feeder allow the folder-gluer’s feeder to run at a higher speed, with a perfect stack height, and without damaging the box blanks.

Our GenieCut In-line Window Patcher is a cutting edge technology that integrates directly onto your current folder-gluer allowing you to window and fold on your finishing line. This innovative machine is unlike other in-line window patchers in that it doesn't have stencils, a cylinder nor a messy glue pot. We are excited about how this revolutionary approach will boost efficiency and productivity for our customers.

Your probably wondering how to calculate your return on investing in folder-gluer peripherals. Check out our Pricing page or Talk to an Expert for ROI exact calculations.

One of the Top Questions we get asked here at IMPACK is: 👉 “Will your machine damage or mark my boxes?” The short answer is no.

![How Can IMPACK Service My Machines If I am Outside of Canada? [+ VIDEO]](https://impack.ca/hubfs/X21-029-1.png)

If you’re on the market for folder-gluer packaging equipment, you’re probably comparing different solutions from several packaging equipment...

If you’re considering purchasing a packer, stacker, box turner, or other packaging equipment, you’re probably wondering how long it would take to get...