Top 10 Frequently Asked Questions About IMPACK’s Packaging Equipment

You’re in the process of deciding on which folder-gluer packer manufacturer you should work with, and you’ve got questions about what it is like to...

7 min read

Marie-Soleil Boutet

:

September 28, 2021

Marie-Soleil Boutet

:

September 28, 2021

You’re considering the purchase of a folder-gluer packer or stacker.

After speaking with an IMPACK Expert, you were asked to fill out our Box Information Template.

And you start to realize that we’ve got questions. Lots of questions.

Now, you’re asking yourself:

“Why is IMPACK asking me all those questions?”

“Why do I need to fill out this form?”

“What are they going to do with all this information?!”

Hi! My name is Marie-Soleil and I am an IMPACK Expert and the Area Sales Manager for Europe, Asia, and South America.

I am very passionate about helping box manufacturers like you achieve their biggest goals, and this question is one that we get asked all the time.

This short VIDEO + ARTICLE will explain to you what a Box Information Template is, why it is so important for you to fill out, and why we ask all those questions in the first place.

The “Box Information Template” is a form we send you to fill out so that we can better understand your production and help you choose the best fitting machine for your production.

Given that we work with small, medium, and large-scale companies, we offer a wide variety of solutions with varying features, capabilities, and levels of automation.

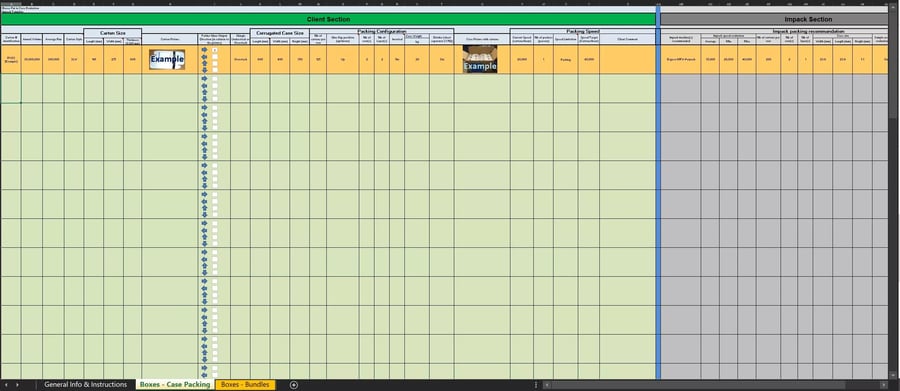

The Box Information Template consists of 2 sections:

Section 1 — General Information: The first section asks general questions about your overall production process.

Section 2 — Production Information: The second section asks specific questions about the types of boxes you produce, the type of process you run, your annual volume, average run-size, and pictures of folded and glued boxes.

🔍 Related: Wondering what are the different options of machines on the market? Discover here "What Are Folder-Gluer Packaging Equipment & Which Machine is Best For You?"

The reason is simple: We understand that each and every company is unique and different.

Every company has its own needs, expectations, and budget.

And we want to make sure that we’re meeting all those needs and exceeding your expectations.

Because we work with small, medium, and large-sized companies, the solutions we offer can vary drastically from one company to another.

And before working with any client, we offer a FREE productivity analysis.

This productivity analysis consists of assessing your production, finishing department’s performance, and level of productivity. It is completely free and commitment-free.

To be able to conduct this free productivity analysis, we have to collect data on your production.

This data is collected using the Box Information Template.

Analyzing the data from the Box Information Template will allow us to pinpoint exactly where bottlenecks are taking place in your production and how we can eliminate them.

This, thereby, will allow us to guide you towards a solution or combination of solutions that will best fit your goals.

🔍 Related: Curious on what machines IMPACK has to offer? Find out "What Are IMPACK's 3 Main Machines (& How to Choose)"

There are 2 reasons why we ask lots of questions:

Because packing systems can become expensive fairly quickly with every mode/feature added.

Because we design and build every machine from scratch based on each company’s distinct needs and requirements.

Very often, we see clients in situations where they have a packing system that either does not do what they bought it to do, or they cannot use half of its features because it doesn’t fit their production and(or) they do not need these features.

At IMPACK, we’re committed to helping box manufacturers maximize their folder-gluer productivity and reach top packing speeds.

Even if that means going with another supplier and not IMPACK.

Hence, we want to offer you the best solution and not the most expensive solution.

The truth is, our target profit margin is the same on all machines.

And with full disclosure: We often even make a much lower profit margin on new high-end products that come with a higher price tag such as the Automatic case feeder (ACF).

So, it is in our best interest to offer you the best machine for your production.

We ask lots of questions as we want to make sure we’re providing you with a machine that will do exactly what you’re looking for because it was designed with your data in mind.

At the end of our data analysis, we will offer you your options and the pros and cons of each option.

You will then have the final say and decide, on your own, which option is ideal for your company.

Except that you’ll be making a smarter decision backed with all your data at hand.

Here are some of the questions you can expect and the reasons behind each:

This is to assess which machine would be compatible with your boxes.

If your box dimensions do not fit our standard packing systems, we will work with our engineering department to explore the option of designing, and building, a customized machine that fits your specific needs.

Custom solutions are not foreign to IMPACK. It is an option we regularly offer to clients!

This is to validate which machine would be best for your cases and whether there is enough free space inside your case to allow a trouble-free packing process.

If your case dimensions don’t fit, we will recommend the appropriate dimensions for you to consider.

This will allow us to see whether there are any special designs, windows, or hooks that could create interlocks when handling the box shingle or when packing the boxes into cases.

This will allow us to see if there are any separators, if some rows are incomplete, or if some boxes are flat packed.

As for crash-lock/auto-bottom boxes, the pictures will allow us to check the ratio between the length and width (including the flaps) as crash-lock boxes have more complex requirements.

These 3 numbers will allow us to calculate the approximate packing speed of your machine, as well as, outline their limitations to you.

For example: If you’re packing straight line boxes at a high speed, then the Virtuo packer could be the perfect solution for you, but if you’re packing with multiple layers, then the Virtuo is not the right solution for you.

Instead, Bobst’s Carton Pack 4, Heidelberg’s Diana Packer, KBA Duran's Omega Pack Station or Ace Machinery’s Sig-Pack would be a better fit.

Those are just some examples of the most common multi-row, multi-layer auto-packers on the market.

🔍 Related: Considering IMPACK's machines but wondering what packing speeds they can reach? Read "What Packing Speeds Do IMPACK's Packers Offer?"

Providing us with the average run and annual volume information for each type of box will allow us to ultimately guide you towards the right machine and the best fitting level of automation.

That is, it will help you decide whether a Manual, Semi-Automatic, Automatic, or Fully-Automatic packing system is best fit for your company.

If there are still uncertainties with some of your boxes, we may then ask you to send us some samples for testing.

🔍 Related: Feeling unsure what level of automation is right for you? Check out our article "What’s the Difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers?"

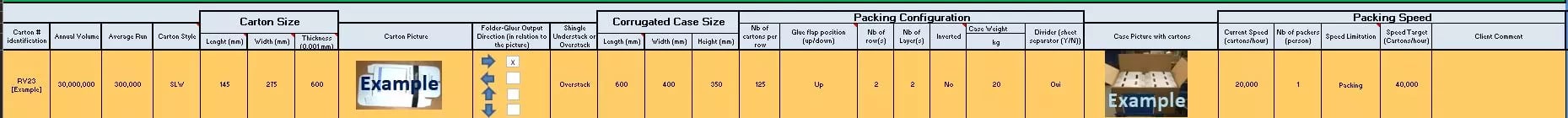

Here is what working with IMPACK will look like and what to expect:

Step #1: After you fill out IMPACK's Box Information Template, we will initiate a free productivity analysis to collect data on your production and pinpoint exactly where bottlenecks are taking place. No commitment required whatsoever.

Step #2: Next, we will analyze this data and determine the best machine for your company. It could be as simple as directing you to a standard packing system, more complex such as building a customized packing system from scratch, or somewhere in between.

We will present you with your options and the pros and cons of each option. And, you get the final say.

If you’re happy with our recommendation, we will move forward to the next step (Step #3).

If IMPACK is not right for you, you’re not tied to us in any way and you get to take your full data analysis with you to help you make a more informed decision and ask the right questions to your future supplier.

Step #3: Then, we proceed to the commercial negotiation (order confirmation, terms and conditions, contract signature, etc.).

Step #4: The next step would be to provide you with the present Lead Time and the estimated Delivery Time while our engineers design and manufacture your brand new machine.

Step #5: And finally, we deliver your machine and administer the commissioning and training at your facility. You can count on IMPACK for complete training for your team on how to use the machine during and after the installation!

🔍 Related: Wondering how long it would take to get your machine delivered? Learn here about IMPACK's Delivery and what to expect.

As we have seen, the Box Information Template’s purpose is to help us better understand your production so that we can determine the right solution or combination of solutions for your company.

In this article, I focused on case packing, but the same considerations apply for bundling/stacking.

Here are the 3 most important takeaways 👇:

The Box Information Template’s purpose is to help us better understand your production so that we can guide you through choosing the best machine for your company's needs, goals, and budget.

The more diligently those questions are answered, the more information we have to help you choose the best machine for your company.

At IMPACK, we never push our clients to buy a machine that has far more features than they need or that outperforms their production. This is because our target profit margin is the same for all machines and even less for more expensive machines.

Remember, our success is directly tied to your success.

We want you to be successful.

Therefore, we want to ensure that we’re providing you with the best machine to help you solve your most pressing folder-gluer problems and achieve your most aggressive goals.

No one enjoys regretting a purchase, especially when it involves investing from your company’s hard-earned money.

And we want to make sure that this never happens.

👉 If you’re still not sure whether investing in packaging equipment is the right move, check out “Do I Need to Invest In Packaging Equipment to Improve My Folder-Gluer Productivity?”

👉 Conflicted on whether a Semi-Automatic packer or an Automatic packer is better for you? Read "Semi-Automatic Vs. Fully-Automatic Packers" and discover which is better.

👉 Find out the best machine for your company by comparing IMPACK’s 3 main machines: “Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer?”

👉 Contact an IMPACK Expert We’d love to answer any questions you’ve got on your mind!

You’re in the process of deciding on which folder-gluer packer manufacturer you should work with, and you’ve got questions about what it is like to...

.jpg)

You're in the process of searching for a packaging equipment supplier to help you improve your folder-gluer productivity and reach higher packing...

If you’re considering IMPACK’s Everio stacker, you’ve probably got lots of questions.