What is the Everio Stacker & What Companies Is It Best Suited For? [+VIDEO]

Are you a medium to large-sized company that is stacking and banding/strapping your boxes fully manually?

5 min read

Stefan Badertscher

:

November 23, 2021

Stefan Badertscher

:

November 23, 2021

Are you looking to automate the bundling of your boxes?

Struggling to improve your productivity on your gluing lines?

You are not alone.

In fact, most box manufacturers that we work with have been in the exact same position that you’re in.

They want to bundle more boxes, faster, and with less manpower so that they can close more contracts and become more productive.

But they’re stuck.

What makes things more challenging is: Finding good operators these days is hard.

And it is becoming rarer, and scarcer, to find skilled operators that are good at what they do.

That's just the reality.

What if I told you that you can fully automate the bundling of your boxes, bundle more boxes, serve more customers, and cut down on costs?

Imagine the impact this can have on your company’s revenues 1 year from today...

“How?”

By integrating a stacker onto your folder-gluer.

At Impack, we teach box manufacturers like you the best practices on how to boost their folder-gluer’s productivity and become top speed producers in their industry.

With over 400 units manufactured and installed across 25 countries, and with projects mapped in over 55 countries, we work with small companies, medium-sized companies, and some of the biggest names in the packaging industry.

This video & article will cover what is a folder-gluer stacker, who needs one, and how to decide whether a stacker is right for your company.

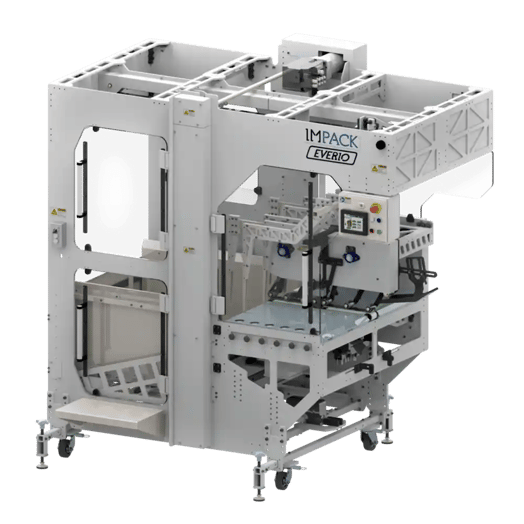

A folder-gluer stacker is one of the 4 main folder-gluer packaging equipment and peripheral solutions that can be added to a folding gluing line.

A folder-gluer stacker is a stacking system that utilizes a modernized bundling technology to allow you to automatically bundle your boxes vertically and then send them for banding/strapping.

In other words, a stacker is a machine that automates your bundling process to help you realize efficiency, speed, and productivity gains.

Depending on your production process, you either pack your boxes into cases (i.e. case packing) using a packer or stack your boxes to be banded/strapped together (i.e. box bundling) using a stacker.

That is, you would either have a packer or a stacker after your pre-packing equipment, but some clients do both processes on the same folder-gluer.

🔍 Recommended: Confused on what machine is right for your company? Read “What Are Folder-Gluer Packaging Equipment & Which Machine is Best For You?”

Just like a packer, a stacker is installed behind — or at the end of a folder-gluer — and after the pre-packing equipment as shown in the image below.

Pre-packing equipment (or pre-packers) includes box turners, batch inverters, and counting and separating devices.

🔍 Recommended: Feeling unsure whether your company needs a packer or a stacker? Find out by reading “Folder-Gluer Packers Vs. Stackers: Which Packaging Solution is Best For You?”

A stacker allows you to:

Take a shingled stream of folded cartons and count them then bundle them.

Band/strap this bundle together (banding/strapping)

Note: Most stacking systems on the market combine a stacker with an automatic banding system, such as ATS, Mosca, or SMB/Signode.

Fully automate and streamline the box bundling process which reduces the workload on your packing staff.

And, as a result, it allows you to improve your folder-gluer’s productivity, reach higher bundling speeds, and cut down on costs.

Box manufacturers who are unable to push their folder-gluer’s productivity to its maximum potential because their packing staff cannot work that fast meaning that the bundling process is the bottleneck of the production line.

Or

Box manufacturers who have large production volumes and want to completely automate the bundling process.

Or

Box manufacturers who simply want to reduce the daily workload on their packing staff which could easily represent lifting 4-5 tons of cartons per day.

So, does your company “actually” need a stacker?

For some companies, a stacker is the perfect fit. And for others, it might be a total waste of money.

But, I won’t leave you at just that.

Here is the concrete answer you’ve been waiting for:

If you can no longer increase the capacity of your folder-gluer because you have pushed your gluer to the limit, ask yourself:

Where exactly is the bottleneck taking place?

Is it at the gluing, bundling, or feeding stage(s)?

The real tipping point between deciding whether you should invest in a folder-gluer stacker or not is the setup time.

In other words, if your folder-gluer could run faster, and your packing staff can keep up with that higher speed, then this is where tuning your gluer would be a better first option than investing in a stacker

👉 If your gluer could go faster, but you’re not sure how to make it run faster, we dedicated a complete article where you can learn step-by-step how to maximize your folder-gluer’s productivity with investing and with $0 investment.

👉 However, if your gluer cannot run faster and your packing staff are exhausted from working hard each day, then this is the best indication that it is time to explore some options of stackers.

Compare the “Top 5 Folder-Gluer Stackers on the Market in 2022” (Coming Soon) to discover what stacker is best for your company.

If you’re exclusively doing banding/strapping, then a stacker, such as IMPACK’s Everio stacker is the best option for you.

🔍 Recommended: Learn more about the Everio stacker and its features and benefits by reading “What is the Everio Stacker & How Can It Improve My Stacking Process?”

If you’re exclusively doing case packing, then a stacker is the wrong fit for you. This is because a stacker cannot do case packing. Instead, you need a packer, such as IMPACK’s Ergosa packer or Virtuo packer.

If you’re doing both case packing and banding/strapping on the same folder-gluer, then you need a packing system that offers both case packing and bundling capabilities, such as IMPACK’s Ergosa packer.

🔍 Recommended:

Learn more about the Ergosa Packer and its features and benefits by reading “What is the Ergosa Packer & How Can it Improve My Packing Process?”

Learn more about the Virtuo Packer and its features and benefits by reading “What is the Virtuo Packer & How Can it Improve My Packing Process?” (Coming Soon)

IMPACK’s Ergosa packer has a module that allows you to push batches of boxes into a banding/strapping machine (like ATS, Mosca, or SMB/Signode) so that they can be bundled together.

So, IMPACK’s Ergosa could pack the boxes into cases just as a packer would do, or be adapted to act as a stacker to stack boxes that are to be banded/strapped together.

I understand that it is not easy to decide on a stacker and it can be even harder convincing people in your organization on why you need one.

Therefore, before you pull the trigger, I strongly recommend that you check out the following articles:

👉 If you’re still not sure whether investing in packaging equipment is the right move, here are your next steps:

To assess whether investing in packaging equipment is the right move for your company, check out “Should I Buy a New Folder-Gluer or Invest in Packaging Equipment to Improve My Productivity?”

Next, read “Do I Need to Invest In Packaging Equipment to Improve My Folder-Gluer Productivity?” to find out whether investing in packaging equipment is worth it for your company.

Finally, learn about the difference between “Folder-Gluer Packers Vs. Stackers” so that you can find out what machine is the best fit for your needs.

👉 If you’ve decided that investing in a stacker is the right choice for your company, here are your next steps:

Learn more about “What is IMPACK’s Everio Stacker & How Can It Improve Your Stacking Process?”

If you’re curious about how much a packer or stacker can cost you, check out our "Pricing" list on our website.

And if you know you need a stacker, but you’re not sure which stacker you should choose, compare the “Top 5 Folder-Gluer Stackers in 2022” (Coming Soon)

![What is the Everio Stacker & What Companies Is It Best Suited For? [+VIDEO]](https://impack.ca/hubfs/X21-042.png)

Are you a medium to large-sized company that is stacking and banding/strapping your boxes fully manually?

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer,...

If you’ve been searching for ways to improve your folder-gluer productivity and reach higher packing speeds, you’ve probably noticed that some of...