What is a Semi-Automatic Packer and How Can It Improve My Packing Process? [+ VIDEO]

If you’re looking for ways to improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach higher speeds, you’re probably...

14 min read

Mathieu Tremblay

:

March 17, 2021

Mathieu Tremblay

:

March 17, 2021

![What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers? [+VIDEO]](https://impack.ca/hubfs/X21-008.png)

If you're a carton box or corrugated board manufacturer that is looking to add a folder-gluer packer or folder-gluer stacker to your folder-gluer, you've probably come across several solutions on the market.Collecting Tables, Semi-Automatic Collectors, Packing Help Stations, Folder-Gluer Packers, and Folder-Gluer Stackers are just some examples of the many solutions on the market.

And different packaging equipment suppliers offer distinct solutions with varying features, capabilities, and levels of automation.

Out of all those options, which folder-gluer packer/stacker is right for you?

How do you go about choosing the best packing system for your company's needs, production, and budget?

The truth is... that choosing a folder-gluer packer or stacker depends on what extent you want to automate your packing process.

This article and video will break down for you the different levels of automation on the market, and how they compare to one another, so that you can discover what folder-gluer packer is best for you.

"Should I go with manual packing help/aid like a Collecting Table or a Fully-Automatic packer?"

This question is the #1 question box manufacturers, like you, ask us when they are looking for a folder-gluer packer or folder-gluer stacker.

And the reality is that there are more than those two options.

In fact, Manual packing and Fully-Automatic packers are the two opposite ends of the spectrum of automation, but there are many other solutions in between those two that most companies shy away from mentioning.

And that is simply because they want to sell you their more expensive machines.

All machines on the market fall into 4 levels of automation: Manual packing, Semi-Automated packing, Automated packing, and Fully-Automated packing.

And this applies to pre-packers, packers, stackers, and pre-feeders.

Before we explain the difference between those 4 levels of automation, it is important for you to know that the definitions of those four levels are our own definitions and not dictionary definitions.

They are always relative to what happens after the folder-gluer. That said, those 4 levels of automation are the “informally accepted” industry-standard categories that group the different types of folder-gluer packers (or packing systems).

Makes sense? Let’s dive right in!

The Manual category is the starting point of the folder-gluer operation where the whole packing process is done manually.

At the lowest end of the manual category, clients would be packing directly at the end of the folder-gluer's compression belt.

In other words, they would crowd a bunch of people at the end of the gluer compression belt and ask them to pack as fast as they can. Fortunately, we rarely see this happening anymore.

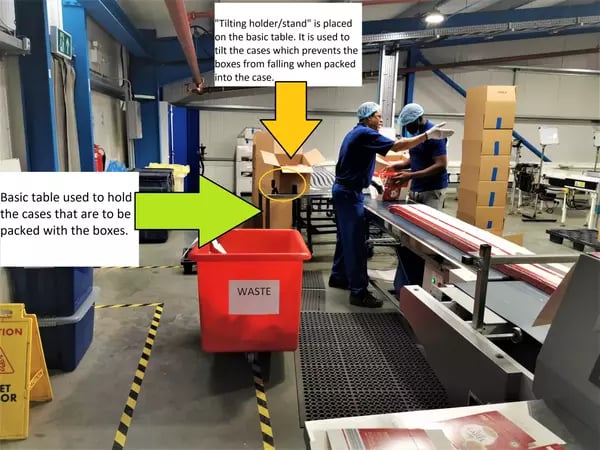

In addition, clients would usually have the most basic tables made of wood or stainless steel and “tilting holders/stands” used to tilt the cases which are to be packed with the boxes.

An example of this that we saw in one of our client visits is shown in the image below:

The first step forward would be to add a conveyor after the folder-gluer's compression belt so that your packing staff can accumulate more boxes per meter of conveyor. This conveyor is called an “accumulation conveyor.”

The accumulation conveyor reduces the speed of the shingle and allows more boxes within the same time frame. It’s more ergonomic, easier to keep up with the speed, and far more convenient to work with multiple people.

The next step would be to upgrade from your basic tables with tilting holders/stands to “actual tilting tables.”

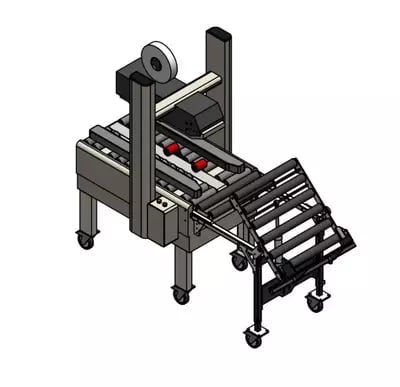

The 3D image below shows an actual tilting table:

Typically, at this stage, those tilting tables do not yet have any automation or pneumatic but just the stand holding the case that you can push onto a conveyor.

Most often, we see those tilting tables locally made from wood or stainless steel and are used to hold the cases so that they’re tilted at an angle. The purpose of tilting the cases is to prevent boxes from falling when placed into the case.

Another step forward would be adding a box turning feature.

This box turning feature allows you to rotate your boxes 90° to the left, or 90° to the right, and control your box orientation to meet the requested case packing configuration. If not turned, your boxes would come out standing up which would require you to manually turn them 90° to place them into the case.

So what a box turner really does is present/orient the boxes in a better way for the packing person(s) to facilitate the packing.

With the implementation of all the previous steps, you would now have the most common “Packing Help” or “Packing Aid” machine within the Manual category: A Collecting Table.

Displayed below is an image of a Collecting Table in action from one of our clients:

Bobst’s Handypack GT, KBA Duran's Omega Pack Station, and Tünkers' FAS 480 are some examples of the most widely present Collecting Tables in Western countries.

At IMPACK, our Collecting Tables are the “Packing Help Stations”

The most popular Collecting Tables on the market all have a right angle on the left or the right with a box turning feature and some form of tilting table (whether a basic table or an actual tilting table).

The tilting table’s level of automation always depends on the product specifications of each respective company.

Some offer more capabilities than others. Ask your packaging equipment supplier about their tilting table’s specifications and level of automation.

But just like with the traditional manual packing process, you still have to pack your boxes by hand on the Collecting Table and do the case flap closing, taping, and ejecting yourself. It’s full manual work with no case management involved.

In other words, although Collecting Tables present the boxes in a better way for the packing person to pack the boxes into the case, they are not automated and have no automation of any form. If a company offers automated case flap-closing and taping with their Collecting Tables, then those are additional configurations that come from third-party suppliers.

Collecting Tables generally have no automation and involve full manual work.

In short, Collecting Tables simply serve as packing help/aid to the traditional manual packing process.

Being able to manage a complete row of boxes in one single motion, rather than by limited batches, is the ultimate tipping point between the manual and semi-automated categories.

For example, the capability of moving 200 boxes into a case — in one single motion — instead of moving multiple, small batches of 50 boxes, or as many as your hands would allow you to lift, is the very first step towards semi-automation.

Knowing that, the integration of case sealing into your packing process is what pushes the needle into the semi-auto category.

🚀 Quick summary: Manual packing is where the entire packing process is done manually. Adding peripheral devices like accumulation conveyors, actual tilting tables, box turners, etc. would serve as a “packing help” or “packing aid” to offer your operators better handling of the boxes. That said, Collecting Tables include no automation, no case management, and is full manual work. The most popular manual packing help/aid is the Collecting Table. IMPACK’s Collecting Tables are the “Packing Help Stations.”

We start talking about a semi-automated process once the folder-gluer packer or stacker includes at least one automated functionality.

This means that the operator of a semi-automatic packer/stacker remains the key factor of the packing process, but with the help of at least one auto feature.

For example, with IMPACK’s Ergosa packer, this auto feature is the case management system. That is, the Ergosa is semi-automatic because it includes an automated case management process.

The first automation step within this category would be, by default, case management i.e. having an automated way of ejecting the case, folding the flaps (manually or automatically), and feeding it to the case sealer.

You could argue that having multiple manual Collecting Tables where all the filled cases, from each station, converge to one automated case sealer that manages the flaps is also a semi-automatic packer.

We could agree with that. It’s certainly a valid argument and is something we very commonly see in our visits to clients’ sites.

But leveraging the versatility of a human being on a Collecting Table does not stop at the case management. There are a multitude of ways to further push the scope of your automation and boost your folder-gluer's productivity.

Some examples include having an automatic pusher to fill the cases, integrating an automatic counting and separating device to keep the count of boxes, adding an automatic batch inverting module for crash-lock/auto-bottom boxes, incorporating a case erector machine, etc.

Some semi-automatic folder-gluer packers are more automated than others.

Given that there are hardly any known folder-gluer packers on the market that could be classified as a semi-automatic packer, we’ll use our semi-automatic packer, the Ergosa, as an example.

There are two versions within IMPACK's Ergosa series: Ergosa A and Ergosa C.

The Ergosa A offers 2 packing modes:

The “Horizontal Mode” for small to medium-sized boxes including straight lines, 4-corners, and 6-corners with multi-row, multi-layer packing capabilities.

The “Pick & Place (or Manual) Mode” for complex boxes that require constant adjustments and corrections, as well as, crash-lock/auto-bottom boxes.

The Ergosa C offers the same 2 packing modes above + 1 additional optional packing mode and several additional benefits:

The “Vertical Mode” with the PerPack Module for medium to large-sized boxes including straight lines, 4-corners, 6-corners, and crash-lock/auto-bottom boxes (if paired with an MFA Batch Inverting Module) with one or two-row(s), one-layer packing capabilities.

The versatility and modularity of the Ergosa packer gives you the flexibility to custom configure your machine and increase the scope of your automation through the addition and omission of multiple modes and options.

This means that you have the capability of adding and removing any of those aforementioned modes based on your production requirements. This way you never have to pay for a specific mode that you would never really use.

Thus, with each additional mode (Horizontal Mode, Vertical Mode, and Pick & Place Mode) and(or) custom configuration that is added, you increase the scope of your automation within the semi-auto category.

Once you’ve added all three modes (or a combination of them), you can further increase your level of automation by integrating an INTRO Module to the Ergosa for separation. This allows you to fully automate the counting and separating of your boxes.

The highest level of automation within the semi-automatic category would be adding an MFA batch inverting Module to the Ergosa C packer in Vertical Mode to process crash-lock/auto-bottom boxes.

This is where you can truly leverage the dexterity of an operator.

Crash-lock/auto-bottom boxes can come in different shapes, varieties, types and sizes with so many possibilities of interlocks and so many ways by which you can move the boxes.

Hence, having a robot manage all this without failure is almost impossible.

Well — maybe not “impossible” per se, given that in 2020, NASA already launched a spacecraft to Mars but it’s challenging, expensive, and only fitting for specific types of productions.

So, there’s absolutely no way that you could process complex boxes (like crash-lock/auto-bottom boxes) with the budget range of a semi-automatic packer using an automatic packer.

The more you try to automate a human, the more complex and costly it gets.

This is what leads us into the auto category!

🚀 Quick summary: A semi-automatic packer is a folder-gluer packer that offers a semi-automated packing process. It includes at least one automated function and the operator is still the key factor of the packing process, but with the help of at least one auto feature.

The versatility and modularity of a semi-automatic packer allows you to custom configure your machine, and increase its level of automation, according to your production objectives. The “Ergosa” is IMPACK’s semi-automatic packer with the performance of an automatic packer, and is our most top sold folder-gluer packer.

Interested in learning more about IMPACK's Ergosa packer, its features, and benefits? Read "What is IMPACK's Ergosa Packer & How Can It Improve My Packing Process?"

Wondering what packing mode of the Ergosa packer is best for what types of boxes? Check out "What are the Ergosa Packer’s 3 Main Packing Modes & What Mode is Best For My Production?"

Time for some complete and raw honesty:

The truth is, a lot of clients get very excited when companies propose and discuss automation and full automation solutions.

And it can be an easy sale for us, packaging equipment suppliers, driven by the client’s pure temptation of having a robot doing the whole job, but that’s the perception in theory.

In practice, things are very different, and we want to make sure that you’re aware of this before you commit to any packaging equipment supplier.

You can add as many automatic features as you want to a semi-automatic folder-gluer packer, but the reality is that as long as the operator is actively involved in the packing process, it’s still a semi-automated process.

Now, it becomes an automated process once the involvement of an operator is strictly limited to background tasks such as feeding the folder-gluer packer with empty cases or managing full cases.

Although their involvement is limited, the operator is still there. Humans are still part of the auto process.

And if anyone tells you otherwise, they’re probably misinformed.

Whether for efficiency or ergonomic reasons, a human is still present and working hard in an auto process.

Yes — all the groundwork, including putting all the boxes into the case is now automatically done by the machine, but just like with a semi-auto process, the operator is still there in an auto process.

They are still on site,

They are still part of the cost,

They are still on the payroll,

It’s the same person with the same job title under the same job description doing (more or less) the same job.

And this applies to IMPACK’s Virtuo packer or any of the other popular automatic packers on the market like the CartonPack, Diana Packer, or J-Pack.

So, here’s an interesting question for you 👇:

If the operator is required for the operation of an automatic folder-gluer packer – just like they are with a semi-automatic folder-gluer packer – and you’re capable of reaching the same speed of an automatic packer with a semi-automatic packer, why would you pay a higher price for an automatic packer?

There is no packer on the market that can fully copy a human’s hand movements. It is so natural for a human to pick up a box out of the shingle when there’s a problem.

And admittedly, it’s just as easy to fancy the thought of automating the hand movements of an operator, but when you start thinking about the mechanics involved, you’re hit with the unfortunate realization that it’s virtually impossible for a robot to copy all those natural human movements.

You can argue that there are fully automated robots for palletizing that can imitate most of the human’s movements, and that is undeniably correct.

But it’s important for you to know that with those projects, the scope is very clearly defined, always the same, never changing, and always accurate and perfect.

What happens if a slight modification is needed?

The robot completely fails.

But a human will just adapt: There’s a box sticking out or pushed forward…a human can just fix it with their own hands.

You just cannot automate every action a human does.

We organize everything around the folder-gluer packer so that the process is as automated and efficient as possible, but we rely on the human to make it possible.

You can certainly attempt to imitate a lot of those human movements through automation, just like you can launch a spacecraft to Mars, but the question is: At what cost are you willing to do so?

Would you be willing to pay millions of dollars for a machine that is fully automated and perfectly dedicated with zero margin for error but yet has a complete lack of forgiveness towards modifications?

This is where realism must be integrated into your decision-making process: There’s always going to be a tradeoff between versatility and performance.

You cannot have the versatility of a semi-automatic packer with an automatic packer, but you can reach the performance of an automatic packer with a semi-automatic packer: A critical point to acknowledge.

🚀 Quick summary: An automatic packer is a folder-gluer packer that offers an automated packing process. The machine becomes the key factor of the packing process and the operator is now limited to performing background tasks such as feeding the folder-gluer packer with empty cases or managing full cases.

That said, the operator is still permanently present and required to operate the automatic packer, just like they are with a semi-automatic packer, except that the process is more automated with less versatility but more performance. The “Virtuo” is IMPACK’s automatic packer.

This is the “holy grail” of automation where everything runs by itself — quite literally.

In other words, the whole packing process becomes automatically managed without requiring the presence of an operator (or other humans) while running.

So, going full-auto would mean automating what the human was previously doing in the auto process which is to place the empty cases into the machine.

In the fully automated process, the machine can now place the empty cases by itself then take the filled cases and seal them fully automatically.

The operator is only ever involved during setups and adjustments. But once the machine is set up and running, the operator can move to higher value-added activities.

The investment here can be exponential because a human can always do things that a machine cannot, or can but at a drastically higher cost.

But more critically, going fully-auto won’t make you go faster. That is a very common misconception.

Why?

In a fully-automated process, you are, in essence, automating the human that just used to put empty cases into the machine.

This operator was never really a bottleneck so the folder-gluer packer would never be limited by this person who’s simply putting empty cases into the machine.

The folder-gluer packer was already doing everything else automatically in the automated process and removing that operator who simply fills the cases won’t make you go any faster. You would run at the same speed but with better performance.

🚀 Quick summary: A fully-automatic folder-gluer packer is the highest level of automation where your entire packing process becomes fully-automated. No human presence required.

The machine fills itself with empty cases then takes them and seals them fully automatically without requiring the presence of an operator. A fully-automated process won’t make you run faster but rather at the same speed with better performance. The “Virtuo + ACF” is IMPACK’s fully automatic packer, and the only 100% fully automatic folder-gluer packer that exists on the market for both corrugated and carton boards.

Conflicted on whether you choose a Semi-Automatic packer or an Automatic packer? Compare “Semi-Automatic Vs. Fully-Automatic Packers" to find out which is better for your company.

Next, compare "Automatic packers Vs. Fully-Automatic packers" to arrive at the best folder-gluer packer for your company's needs, production, and budget.

"So, which packer is best for my company?!"

The answer to this question is far from an easy “one-size-fits-all” response.

It all depends on your product mix, type of production, box configuration, individual needs, and a set of intertwined factors.

A Collecting Table (manual packing) is usually the default choice clients go for when there’s not much thought or analysis being factored into the decision-making process.

At this stage, clients would have usually tried everything to increase their folder-gluer productivity without investing but their folder-gluer has hit its maximum potential.

You see, no matter how much you organize your workflows, standardize your machine setups and optimize your production sequences, there will come a point where your folder-gluer will hit maximum speed and there’s nothing you can do to make that machine run faster without additional solutions.

It’s simply inevitable.

Hence, the first step a client would take is adding a packing help/aid to their traditional manual packing process such as a Collecting Table. And this decision is very often done under the thought process of “everyone else has it, so let’s buy it.”

No questions asked.

If you have small production runs with a lot of changes per shift, and you’ve never had any “packing help” or “packing aid,” then a Collecting Table like IMPACK’s Packing Help Stations — or the other Collecting Tables on the market — could be a great first step to help facilitate your packing process by better presenting/orienting your boxes for your packing person(s).

Now, there will come a point where your Collecting Table will become limited by its manual functionality which is really the tipping point from manual packing to semi-automatic packers.

That said, you can push your Collecting Table to do more than what they are doing. In other words, all Collecting Tables can be easily adapted to make them semi-automated.

Most companies won’t do it though because, naturally, they want you to opt for the semi-automatic or automatic folder-gluer packers that come with a much higher price tag.

But it is certainly possible, easy, and inexpensive.

At IMPACK, we are not exclusive to a specific category.

Yes — we do standardize our machines to keep volume and production cost under control, but we are not exclusive from a technical standpoint.

If you prefer to expand the capabilities of your Collecting Table instead of investing in a new machine, we are open and willing to help you do whatever you feel is best for you.

What we very commonly see are clients that start with a Collecting Table and once they get limited by the manual process, they themselves try to automate those solutions by adding auto features.

Sometimes they’re successful, sometimes they fail, and sometimes they come to us because they failed.

Now if you have a wide range of boxes, complex boxes, or a diverse product mix that requires constant adjustments and corrections, a semi-automatic packer like IMPACK’s Ergosa could be an ideal solution.

And the tipping point from semi-auto to auto is the same as that from manual to semi-auto. This is because there’s not really a transition between semi-auto to auto. Usually, a client starts with a manual process then goes either the semi-auto path or the auto path.

If you have longer production runs, easy products, and all the requirements for auto then you can go the auto path.

And then to further improve efficiency and remove all humans involved, you can go fully auto. But this depends on whether you have the right conditions, the required floor space, the flexible budget, and the perfect product mix.

Your forecasted ROI and product mix (both existing and predicted future mix) will be the key deciding factors that justify which investment will yield the best payback for your company.

Now that you have a clear understanding of the 4 different levels of automation, it's time for you to compare different packing/stacking systems:

Start by comparing Manual, Semi-Auto, Auto, and Fully-Auto Folder-Gluer Packers and learning about their pros and cons to know what level of automation is right for your company.

Next, if you're conflicted about whether you should go for a Collecting Table like Bobst’s Handypack GT or a Folder-Gluer Packer, check out the article "What's the Difference between Collecting Tables and the Ergosa Packer?"

Then, find out How Much a Folder-Gluer Packer Could Cost You and what factors drive the cost up or down.

Finally, discover what folder-gluer packer is right for you by reading "What Folder-Gluer Packer Is Right For You?"

![What is a Semi-Automatic Packer and How Can It Improve My Packing Process? [+ VIDEO]](https://impack.ca/hubfs/X21-057.png)

If you’re looking for ways to improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach higher speeds, you’re probably...

You and your competitors have 1 common goal:

![Folder-Gluer Packers: What Level of Automation Is Right for You? [+VIDEO]](https://impack.ca/hubfs/X22-039-1.png)

Are you considering investing in a folder-gluer packer or folder-gluer stacker?