How to Raise Your Folder Gluer's Outfeed Height (& Why You Need To)

You're considering adding a packer or stacker to your folding gluing line to help you speed up your case packing process. After having your first...

5 min read

David Leblanc

:

October 5, 2021

You’re considering adding a packer or stacker to your gluing line.

After having your first meeting with IMPACK, and deciding on the best machine for your company, you received a request that you need to increase your folder-gluer’s outfeed height.

You consulted your folder-gluer manufacturer or equipment supplier, and they told you that it cannot be done or that the warranty on your folder-gluer may no longer apply.

Now, you’re asking yourself:

“Why do I need to raise my folder-gluer’s outfeed?”

“Will this affect my folder-gluer’s performance?”

“And do I absolutely need to raise my folder-gluer’s outfeed?!”

Frustration, doubt, and panic set in as you start feeling like you may have made a mistake with purchasing a machine from IMPACK.

I totally get it.

As a Mechanical Designer and Project Engineer at IMPACK, I have led the design and installation of hundreds of packaging equipment on folder-gluers in the last 4 years.

And our team gets asked this question many times a week.

Here’s the good news: Increasing the height of your folder-gluer’s outfeed does not affect your folder-gluer whatsoever.

This ARTICLE + VIDEO will explain why you need to increase the height of your folder-gluer’s outfeed, whether it affects your folder-gluer’s performance or warranty, and how to increase the height of your folder-gluer’s outfeed.

And I promise I will keep this short and simple.

If you’re considering the purchase of IMPACK’s Ergosa packer, then there are 2 reasons why you'd have to increase the height of your folder-gluer’s outfeed:

Ergonomics

Case specifications

The first reason is simple: For Ergonomics.

After many years of constant testing by our engineers and regular feedback from our clients, we managed to find the ideal height for the Ergosa packer that will maximize ergonomics for your operators and allow them to maintain high packing speeds in the long run.

This ideal height for the Ergosa packer is approximately 870 mm.

IMPACK’s Ergosa is designed and built around this ideal height.

Therefore, to ensure that your Ergosa is as ergonomic as possible for your operators and that they are capable of maintaining a high performance, in the long run, we have to increase the height of your folder-gluer’s outfeed to match the ideal height of the Ergosa packer.

“But, can the working height of the Ergosa be changed?”

Good question! The answer is yes, the working height of the Ergosa can be changed, but it is strongly not recommended.

“Why so?”

This brings us to the second reason: Case specifications.

We can certainly change the input height of your Ergosa packer.

However, if we do so, you will not have the same case specifications or achieve the same performance with your Ergosa if this ideal height were to be changed.

Given that the Ergosa is a highly modular and versatile packer that offers multiple packing modes, we cannot guarantee that it would run with the same performance and speed as what we had discussed in our first meeting if we were to change this height.

And, we also might not be able to retrofit additional packing modes or modules in the future if we were to change this height.

In short, although we can change the ideal height of your Ergosa, we do not recommend it because it will affect your performance, packing speed, and level of flexibility.

🔍 Recommended:

👉 What is IMPACK’s Ergosa Packer & How Can It Improve Your Packing Process?

👉 What Are the Ergosa’s 3 Main Packing Modes & Which Mode is Best For What Box?

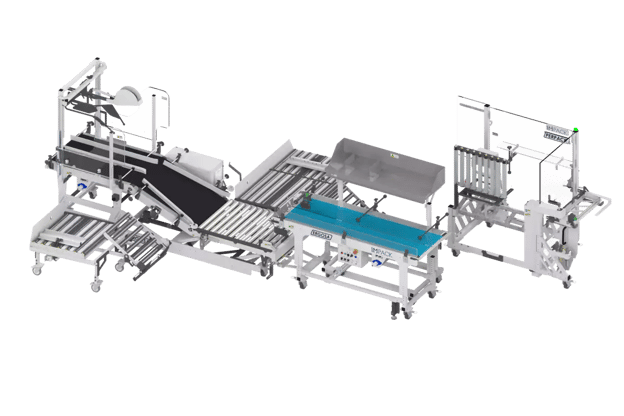

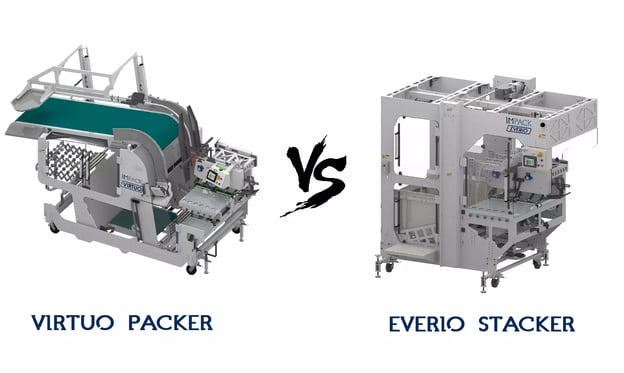

If you’re considering the purchase of IMPACK’s Virtuo packer or Everio Stacker, then there is 1 reason why you'd have to increase the height of your folder-gluer’s outfeed:

And the reason is to meet case specifications.

With our Ergosa packer, we mentioned that you have to increase the height of your folder-gluer’s outfeed for ergonomics and to meet case specifications.

In contrast, when you’re considering the Virtuo packer or Everio Stacker, ergonomics is irrelevant because those machines are automatic and fully-automatic respectively.

This means that there is no human actively working on the machines and hence ergonomics is irrelevant.

The main reason behind why you have to increase the height of your folder-gluer’s outfeed with the Virtuo packer or Everio stacker is to meet case specifications.

Given that both IMPACK’s Virtuo packer and Everio stacker have many important specifications, lowering their input height would reduce their performance.

“But can the input height of the Virtuo or Everio be changed?”

The answer is no, the input height cannot be changed for the Virtuo packer or Everio stacker.

This input height is fixed in the design of those machines unlike with the Ergosa packer where the working height can be changed.

🔍 Recommended:

👉 What Are IMPACK's 3 Main Machines & How to Choose?

👉 Ergosa Vs. Virtuo Vs. Everio: Which Machine is Right For You?

The answer to this is straightforward: It won’t.

Increasing the height of your folder-gluer’s outfeed will not damage your boxes and will not affect your folder-gluer’s compression belt, or performance, whatsoever.

In fact, it won’t change a thing.

We have tested this over 200 times and there has been no negative feedback or effects of any kind on our clients’ folder-gluers.

In addition, we have never heard from any client that their warranty was voided because of a defect to their folder-gluer’s compression belt or that their compression belt was affected in any way.

So, if your folder-gluer manufacturer or equipment supplier told you that increasing the height of your folder-gluer’s outfeed will affect your folder-gluer, they are probably misinformed.

Now that you have a better understanding of why we have to increase the height of your folder-gluer’s outfeed, and its importance to your performance and packing speed, you’re probably wondering:

“How do I increase my folder-gluer’s outfeed height?!”

There are 2 main ways to do this:

Using the screws at the base of your folder-gluer’s legs (if your folder-gluer has adjustable legs)

By adding shims to raise the legs of your folder-gluer’s outfeed

Most folder-gluers have adjustable legs.

In most cases, we can increase the height of your folder-gluer by adjusting the screw at the base of your folder-gluer’s legs.

However, with some folder-gluer models, it may be impossible for you to adjust the screw because those folder-gluers do not have adjustable legs.

In those specific cases, we can very simply add “shims” to raise the folder-gluer’s outfeed as shown in the image below. Problem solved!

At IMPACK, we provide standard shims that fits most folder-gluers on the market.

“But why can’t I just lift the whole folder-gluer?”

This is a question that we get asked all the time. And the answer is:

You can, but it is unnecessary.

Lifting the output of the folder-gluer works perfectly and is sufficient to match the ideal height of your chosen packer or stacker.

Thus, you do not need to go through the hassle of lifting the entire folder-gluer.

So, there you have it.

As we have seen, regardless of which of IMPACK’s 3 main machines you’re considering, you need to increase the height of your folder-gluer’s outfeed to meet the ideal height of your chosen machine.

With the Ergosa packer, you can change this ideal height, but it is not recommended.

With the Virtuo packer or Everio stacker, you cannot change this ideal height as it is fixed.

Increasing the height of your folder-gluer’s outfeed will not damage your boxes, affect your folder-gluer’s performance, or your warranty in any way whatsoever.

It won’t affect your folder-gluer at all.

If you already purchased one of IMPACK’s 3 main machines, and you’re waiting for the commissioning, you’re now 1 step closer to a smooth and seamless installation.

If you’re still considering purchasing a machine from IMPACK, you’re now fully equipped with all the info you need to make a smarter decision on your investment.

👉 If you’re waiting for the commissioning of your machine, you’d want to learn about the “Top 5 Problems with Folder-Gluer Packer Installations & How to Avoid Them?”

👉 If you’re still not sure whether investing in packaging equipment is the right move, check out “Do I Need to Invest In Packaging Equipment to Improve My Folder-Gluer Productivity?”

👉 Finally, save money by learning about the “7 Hidden Costs with Buying Packaging Equipment & How You Can Avoid Them.”

You're considering adding a packer or stacker to your folding gluing line to help you speed up your case packing process. After having your first...

Are you looking to automate the bundling of your boxes?

![Folder-Gluer Packers: What Level of Automation Is Right for You? [+VIDEO]](https://impack.ca/hubfs/X22-039-1.png)

Are you considering investing in a folder-gluer packer or folder-gluer stacker?