How Do Understack Shingles Affect Your Choice of a Packing System?

So, you’re thinking of adding a packer or stacker to your folder-gluer.

4 min read

Maxime Jacques

:

October 15, 2021

Maxime Jacques

:

October 15, 2021

.jpg)

You’re considering adding a packer or stacker to your gluing line.

You contacted an IMPACK Expert and after a few conversations, you were asked:

“Do you run some of your boxes understack?”

You’re thinking to yourself:

“Why is IMPACK asking me this?”

“Why does this even matter to me?!”

You’ve heard of the term “understack” but you’re not sure if it is the same as what the IMPACK expert is referring to and you don’t understand why you’re being asked this question in the first place.

You see, 99% of the time, box shingles are overstack.

However, in some cases, your operator(s) may need to generate understack shingles.

Understanding what an understack shingle is will greatly influence what packing system is right for you, the packing speeds you can reach, and the amount of money you spend on a packing system.

In other words, it affects your choice of a packing system.

By "packing system," I am referring to any machine you're thinking of adding after your folder-gluer. This includes packers, stackers, and pre-packers.

And this can be a difference of hundreds of thousands of dollars.

As an Electrical Engineer and an IMPACK Expert for over 8 years, I get confronted with this subject all the time.

This article will explain to you the difference between overstack and understack shingles, why it matters to your packing process, and how it affects your choice of a packing system after your folder-gluer.

To better understand the difference between overstack and understack shingles, let’s define both terms.

But first, let’s agree on what a shingle is.

A box shingle is the overlapped stream of folded cartons exiting a folder-gluer’s delivery belt.

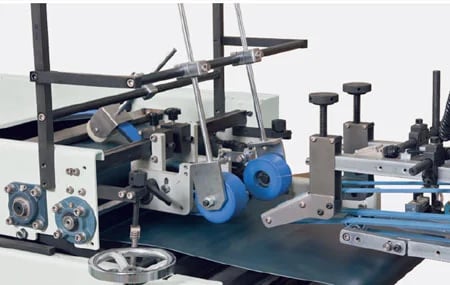

As shown in the image above, each box is offset by a few millimeters from the previous one which forms a continuous flow of boxes.

We call this “flow of boxes” a shingle.

At the entry of the folder-gluer’s delivery belt, the folder-gluer’s trombone deposits the boxes one by one, and offsets them a few millimeters from each preceding one, thus forming a shingle.

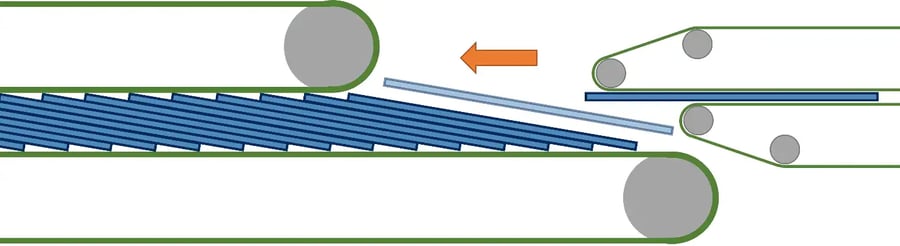

This is demonstrated in the image below:

An overstack shingle is a shingle where the folder-gluer’s trombone stacks each next box over the previous one. Hence the name “overstack.” This is shown in the image below:

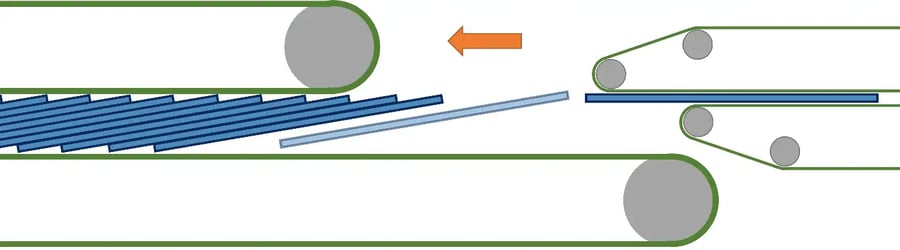

An understack shingle is a shingle where the folder-gluer’s trombone stacks each next box under the previous one. Hence the name “understack.” This is shown in the image below:

Now that we defined overstack and understack shingles, let’s take a look at why understack shingles matter to your packing process.

99% of the time, your operator will set the folder-gluer to produce overstack shingles regardless of the type of boxes being processed.

This is because overstack shingles are the standard.

Overstack shingles are always the standard choice since they are a little easier and faster to set up than understack shingles.

For some 4 corner boxes, however, the operator has no choice but to set the folder-gluer to produce understack shingles.

And, packing systems are strictly designed for overstack shingles and not understack shingles.

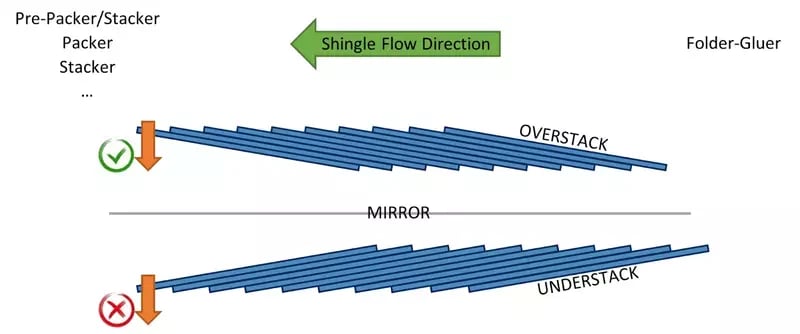

The image below shows an overstack and an understack shingle against one another:

As you can see, an understack shingle is the opposite of an overstack shingle.

To be able to process an understack shingle, your packing system must be capable of working in reverse.

And this applies to any packing system you're thinking of adding after your folder-gluer (whether a packer, stacker, or pre-packer).

Unfortunately though, most packing systems (packers, stackers, and pre-packers) either use gravity to drop the boxes one by one into a case, or they bundle the boxes together.

If you look at the stream of boxes in an understack shingle shown in the image above, you can see that the first box is on top.

Therefore, boxes in an understack shingle cannot fall by gravity. And gravity cannot be reversed.

Understack shingles require a manual packing method or a specific system dedicated to processing a limited percentage of your production.

Alright. We defined what is an overstack shingle and an understack shingle.

We also discussed the difference between overstack and understack shingles and why understanding the difference is crucial.

Here are the 4 most important takeaways you need to know 👇:

99% of the time, your operator will set the folder-gluer to produce overstack shingles.

However, for some 4 corner boxes, your operator has no choice but to set the folder-gluer to produce understack shingles.

If you process a large percentage of understack shingles, this will have significant implications on your choice of a packing system regardless of what packing system you're considering adding after your folder-gluer (a packer, stacker, or pre-packer), the packing speeds you can reach, and the amount of money you spend on a packing system.

Finding a packing system that can process understack shingles is very difficult and extremely expensive.

Now, you’re probably wondering:

“What if I produce some understack boxes, how does this affect my choice of a packing system?”

“Are my options the same or different?”

Our article “How Do Understack Shingles Affect Your Choice of a Packing System?” (coming soon) answers exactly that.

It talks about when understack shingles are used, how understack shingles affect your choice of a packing system, and what packing system is right for you.

👉 Start by learning “How Do Understack Shingles Affect Your Choice of a Packing System?” (coming soon)

👉 Were you asked by IMPACK to increase your folder-gluer's outfeed height and confused why? Find out why you need to increase your folder-gluer's outfeed height and whether it affects your folder-gluer's performance or warranty.

👉 Considering working with IMPACK but still not 100% confident in us as a partner? Here are IMPACK’s Top 10 Frequently Asked Questions with clear and direct answers.

So, you’re thinking of adding a packer or stacker to your folder-gluer.

![How Fast Can I Run With IMPACK’s Packers? [+VIDEO]](https://impack.ca/hubfs/X21-031.png)

You, and everyone else in the packaging industry, want to achieve the same common goal:

![What is a Semi-Automatic Packer and How Can It Improve My Packing Process? [+ VIDEO]](https://impack.ca/hubfs/X21-057.png)

If you’re looking for ways to improve your folder-gluer’s productivity, increase your folder-gluer’s output, and reach higher speeds, you’re probably...