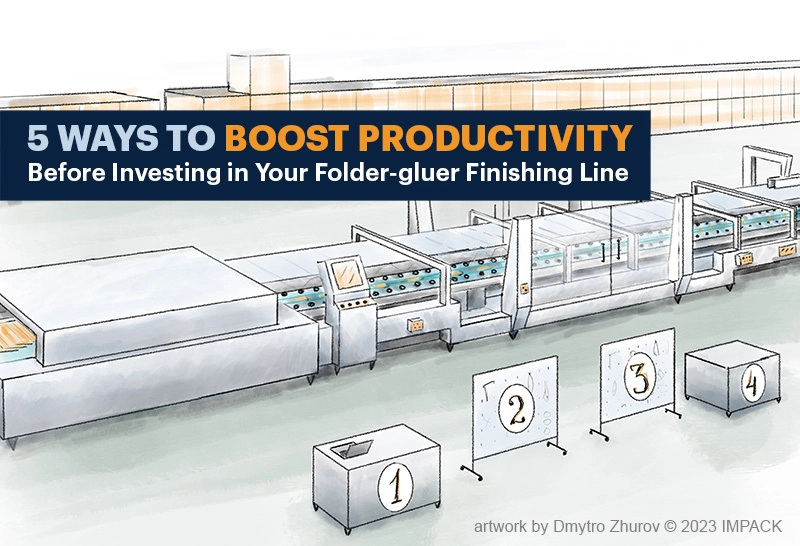

5 Ways to Boost Productivity on the Folder-Gluer Finishing Line Without Investing

Before Investing Optimize Your Existing Processes Every company aspires to increase its folder-gluer productivity and maximize output potential....

4 min read

Mathieu Tremblay

:

November 5, 2025

Mathieu Tremblay

:

November 5, 2025

The work done in the finishing department is still a craft.

Before Investing Optimize Your Existing Processes Every company aspires to increase its folder-gluer productivity and maximize output potential....

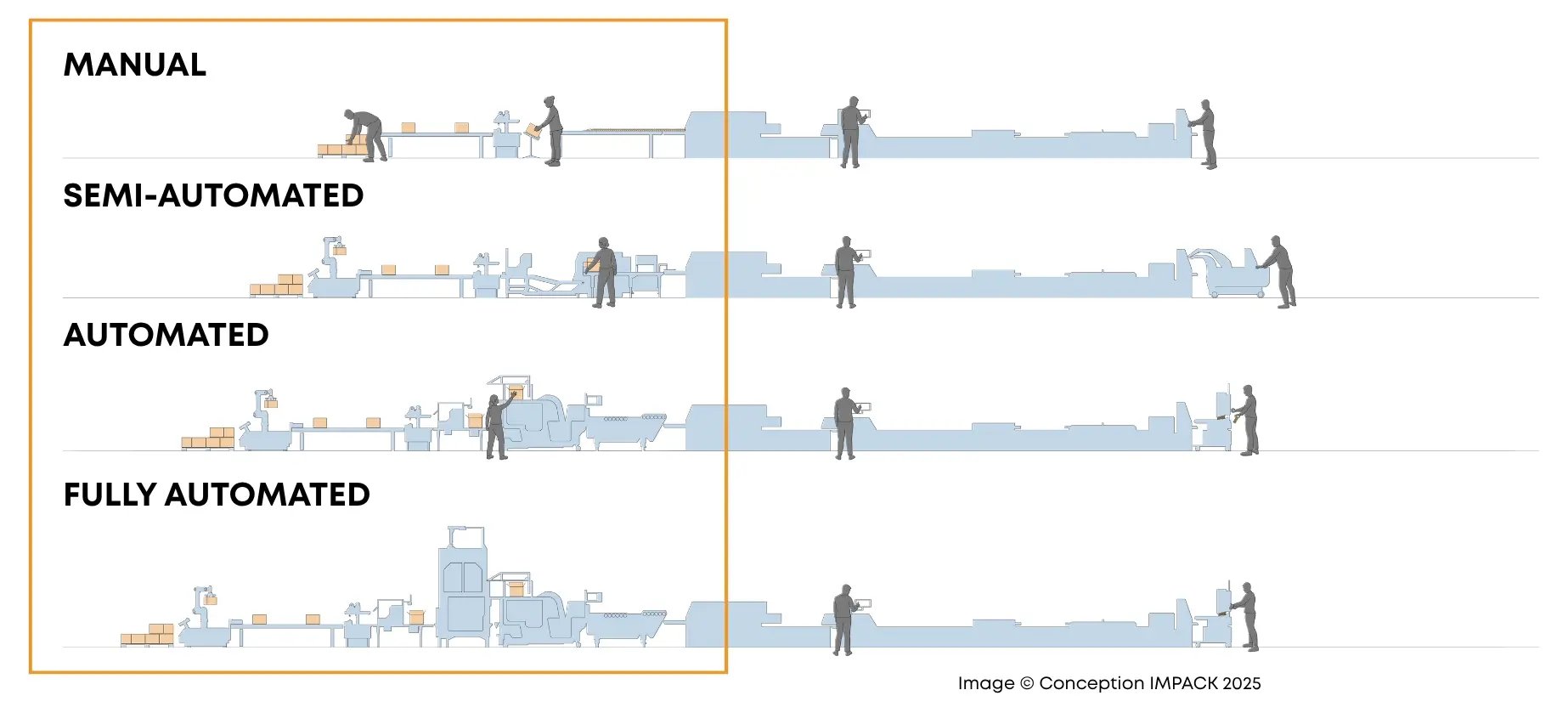

Introducing ergonomics to folder-gluer finishing lines helps carton converters address labor shortages and increase production. Let me explain how.

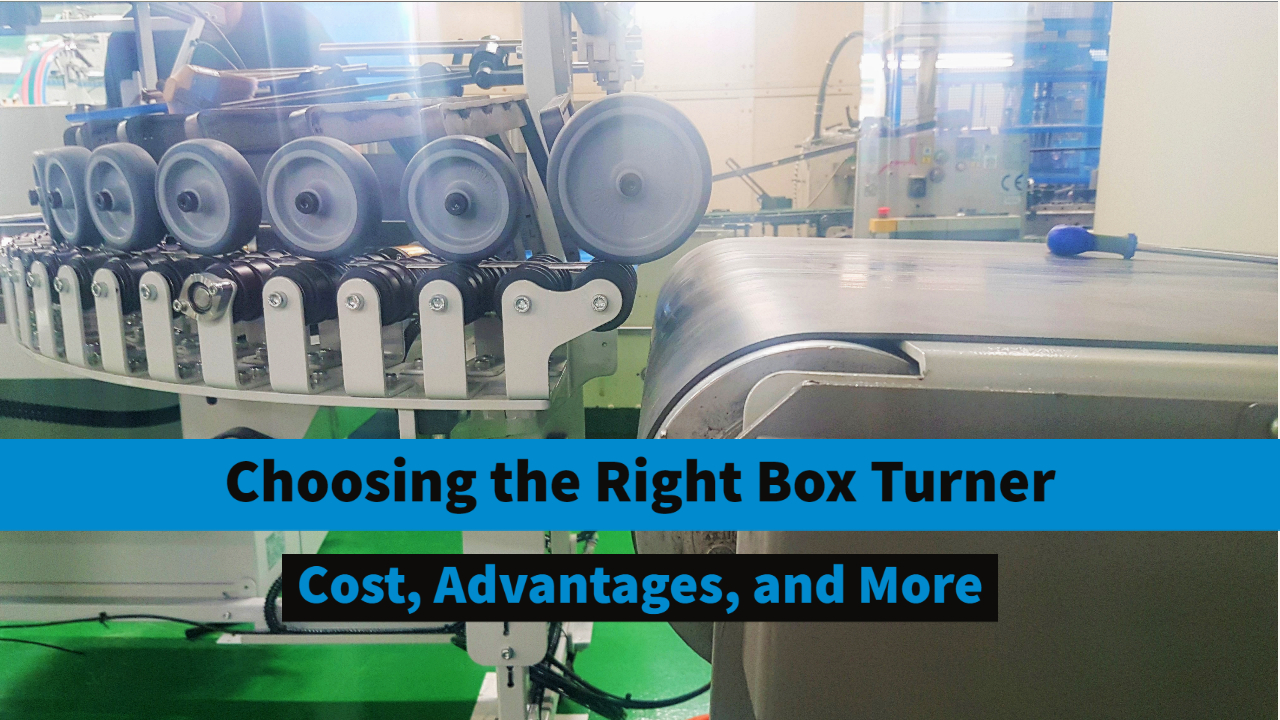

Adding a box turner to the end of your folding-gluing line is almost always essential.