Do I Need to Invest In Packaging Equipment to Improve My Folder-Gluer Productivity?

Are you considering the purchase of packaging equipment to help you improve your folder-gluer’s productivity?

2 min read

Stefan Badertscher

:

March 11, 2023

Stefan Badertscher

:

March 11, 2023

We can break down the different packaging equipment we offer here at Impack packaging into 4 families:

This article will define all four and explore the advantages they offer to your folder-gluer line.

Impack Packaging's Prefio

A pre-feeder is a unit usually located in front of a folder-gluer, before the feeder, that continuously feeds the folder-gluer.

Pre-feeding equipment allows the folder-gluer’s feeder to run at a higher speed, with a perfect stack height, and without damaging the box blanks.

Our pre-feeder is the Prefio: We are proud to say it is the smallest pre-feeder for corrugated board on the market.

A pre-packer is a unit located right after the folder-gluer, and before the packer.

Often, more than one pre-packer unit is installed at the end of the folder-gluer.

Pre-packers vary from box turners, batch inverters, and counting and separating devices.

An important notion to know, some pre-packing equipment allows you to orient the shingle, an overlapped stream of boxes, in the right direction before it enters the case-packing process. This way, the boxes that need to be oriented in any specific way based on their configurations can be turned before they are packed.

Impack’s Ergosa A packer always includes a built-in IN2 or INH box turner as part of the Ergosa A package.

As for the other types of pre-packing equipment, they serve other aspects of your production based on your production needs, box sizes, product mix, and format restrictions.

A batch inverter is typically added to a packer if you produce high volumes of crash-lock/auto-bottom boxes.

A counting and separating device is added to a packer if you have an IN2 or IN3 box turner and when the kicker counter from the folder-gluer is lost in the shingle after the turn.

Let’s now dive into packers!

A folder-gluer packer is a unit installed behind a folder-gluer, every folder-gluer has a packing station no matter how automated it is.

A folder-gluer packer is meant to dramatically improve the packing efficiency, ergonomics, and productivity of your packing process into your cases by automated case management capabilities.

In other words, a packer optimizes your case packing process by automating your packing and sometimes your casing process as well.

Here is a list of Impack’s folder-gluer packers.

Like a packer, a folder-gluer stacker is installed behind a folder-gluer at the packing end of your folding gluing line.

Depending on your production processes, you can either pack your boxes into cases using a folder-gluer packer or you can stack your boxes to be banded or strapped together using a folder-gluer stacker.

In other words, you would either have a packer or a stacker at the end of your folding gluing line.

There are also some clients who do both processes on the same folder-gluer.

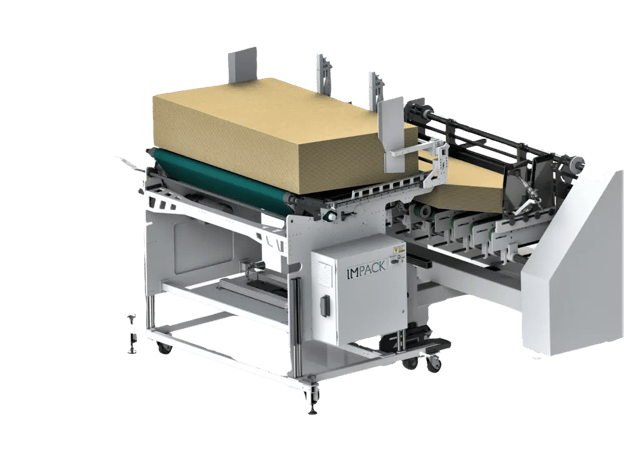

The stacker here at Impack is the Everio stacker.

Now that you know the difference between pre-feeders, pre-packers, packers, and stackers, take a deep dive into the different packaging machines we offer and their advantages.

What is a Folder-Gluer Packer and Who Needs One?

What is a Box Turner and Do I Really Need One?

Folder-Gluer Packers Vs. Stackers: Which Packaging Solution is Best For You?

Are you considering the purchase of packaging equipment to help you improve your folder-gluer’s productivity?

If you’ve been searching for ways to improve your folder-gluer's productivity and speed up your packing, you've probably come across several...

“Why did no one tell me that I have to pay these fees upon delivery?”