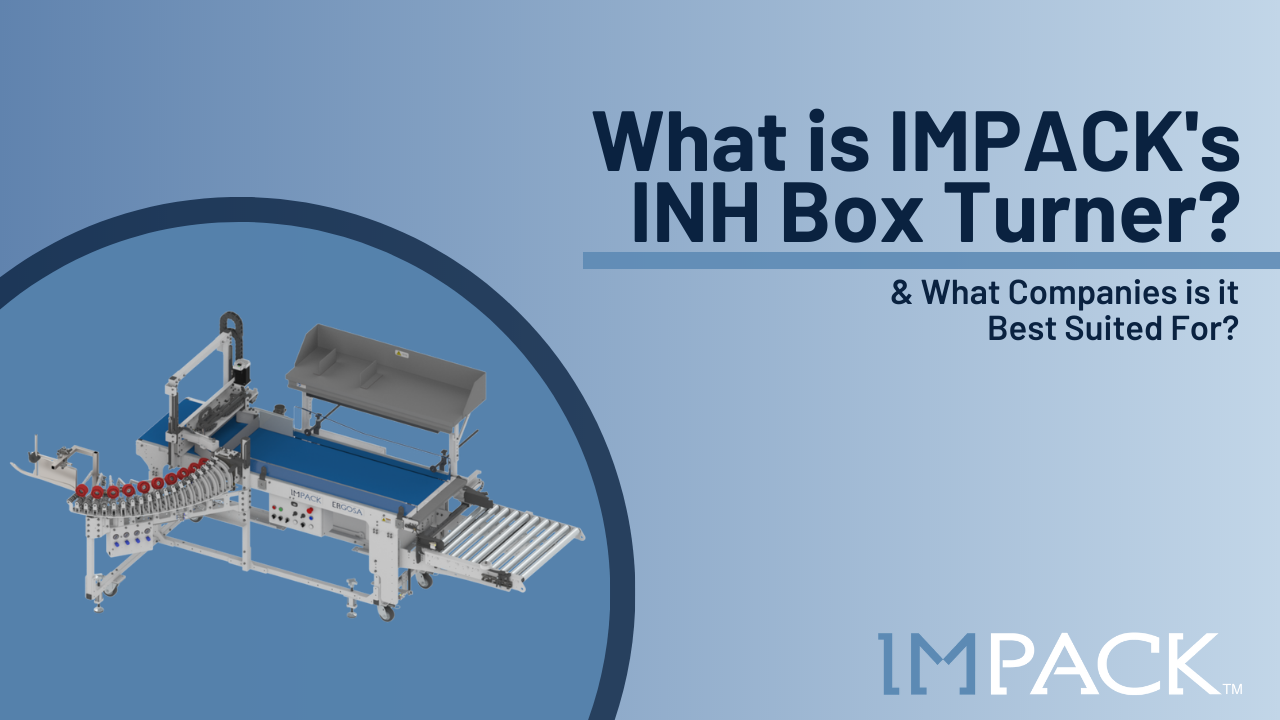

Impack Packaging's INH Box Turner: A Complete Review

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...

If you’re looking to automate the turning of your boxes, you’re probably searching for a box turner.

And choosing the right box turner for your company is no easy task.

Hi! My name is Francois Granger. As a Mechanical Engineer and an Impack Packaging Expert, I have recommended, sold, and administered the testing and installation of dozens of box turners around the globe.

I was also personally involved in the prototype testing, first production unit testing, and the first sale of our newest and latest box turner: The INH Box Turner.

So, the INH is a machine that is dear to my heart and that I know as good as my name!

In my previous article “What is a Box Turner and Do I Really Need One?,” I talked about what is a box turner, its purpose, and who actually needs one.

And, in my other article “Comparing Impack Packaging's Box Turners: Which Is Best For Your Company?,” I compared Impack's 5 main box turners against one another so that you can know exactly which box turner is right for you.

This article will cover Impack's newest and latest box turning technology: The INH Box Turner.

We will discuss what is the INH Box Turner, its pros and cons, and who it is best suited for.

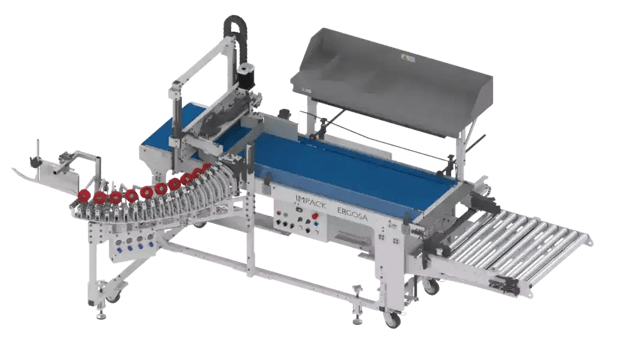

The INH Box Turner is impack packaging's newest box turner with the most advanced box turning technology on the market (patent pending).

Although many packaging equipment suppliers refer to their traditional Collecting Tables as “packers” or “right-angle packers,” those systems are — in the end — just box turners.

And this is not based on opinion but strictly on the evaluation of their technical working principles i.e. the way those machines operate and their features and capabilities.

Collecting Tables simply present the boxes in a better way for your operators to pack the boxes into the case which is exactly what a box turner does and is built to do.

Collecting Tables do not automate your case packing process and have no automation of any form. Instead, they serve as a packing help/aid to the traditional manual packing process.

🔍 Related: Learn here about the difference between Collecting Tables and the Ergosa Packer and how they compare against one another.

“But why are you talking about Collecting Tables?”

Here’s why: While Collecting Tables are box turners too, the INH is the only box turner on the market that can turn your boxes 90° while keeping the packer in alignment with the folder-gluer.

In other words, what makes the INH Box Turner different from the traditional Collecting Tables and every other box turner on the market is that it keeps the shingle going straight so that your downstream equipment is aligned with your folder-gluer.

This means that none of your equipment will have to be positioned sideways or angled 90° to the left or right.

Your boxes will continue in the gluing direction of the folder-gluer and the equipment will not require additional lateral space.

Because the INH Box Turner can be installed directly after the folder-gluer’s delivery belt with an Impack packaging's Ergosa packer, it is the most compact helicoidal turner in the world.

By accumulating the boxes on their edge, it reduces the shingle speed to the minimum possible speed at the packing station, thus giving your operators plenty of time to pack the boxes efficiently and it enables you to maximize your folder-gluer’s productivity.

Impack's Ergosa A packer already includes a built-in box turner.

This built-in box turner is very often the IN2 Box Turner as it is the most cost-effective solution for box turning.

However, as of 2021, the INH is becoming the top chosen built-in box turner.

As for the Ergosa C packer, it does not include a built-in box turner (in most cases).

Almost every single Ergosa C is paired with a stand-alone IN2 Box Turner.

That said, there is an exception: When the Ergosa C packer is sold with an INH Box Turner, the INH is built into the Ergosa C.

Therefore, the INH is the only box turner that is built into the Ergosa C packer.

In short, the INH is built into the Ergosa A packer and Ergosa C packer if chosen as the preferred box turner.

The Ergosa A — INH and the Ergosa C — INH combinations are the 2 most efficient and versatile Semi-Automatic packers offered by Impack packaging.

Impack's newest innovation with the latest box turning technology on the market.

Keeps the count from the folder-gluer’s kicker.

Compatible with small to medium-sized boxes.

Installed directly after the folder-gluer’s delivery belt with Impack packaging's Ergosa packer

Offers you 2 possible turning orientations: 90° or straight through.

The most compact of all helicoidal turners on the market.

Allows you to accumulate boxes on their edge and maximize the density of the accumulated boxes. This means more boxes per meter of conveyor.

Keeps the count from the folder-gluer’s kicker.

Just like the IN2 Box Turner, the INH Box Turner is a very compact box turner when compared to Collecting Tables that have a Helicoidal section, such as Bobst's Handypack GT and other similar Collecting Tables on the market.

Just like the IN2 Box Turner, the INH Box Turner allows your boxes to continue in the gluing direction of the folder-gluer and your equipment will not require additional lateral space. In contrast, Collecting Tables have a Helicoidal section which always turns the boxes 90° hence requiring additional lateral space.

The INH Box Turner is not compatible with all boxes made of corrugated board. Some boxes may be damaged by the helicoidal path that is exposing them to torsion.

As we have seen, Impack packaging's INH Box Turner is the most compact helicoidal turner on the market that keeps the count from the folder-gluer’s kicker, keeps the shingle going straight so that your downstream equipment is aligned with your folder-gluer, and offers the most advanced box turning technology that no other box turner on the market offers.

That being said, no solution in the world is perfect for every company.

Our INH Box Turner might either be the ideal solution for your company or simply be the wrong fit.

That’s just the reality.

“So, is the INH Box Turner right for my company?”

Here is your answer in less than 50 seconds ⏱️:

You intend to invest in a Semi-Automatic packer.

Marking boxes with an optical brightener is an issue for your company or your customer.

You want to facilitate an easier packing process for your operators that are using manual packing stations by turning your boxes 90°.

Boosting your folder-gluer productivity and reaching higher packing speeds are your top priorities.

You are processing a large percentage of straight line boxes made of folding carton.

You do not intend to invest in a Semi-Automatic packer. Instead, you intend to invest in an Automatic or a Fully-Automatic packer.

Marking boxes with an optical brightener is not an issue for your company or your customer and you're not looking for the most advanced box turner on the market. Here, Impack's IN1 Box Turner or IN2 Box Turner could be better options.

Boosting your folder-gluer productivity and reaching higher packing speeds are not your top priorities.

You are not processing a large percentage of straight line boxes.

You want to process corrugated board or micro-flute boxes.

🔍 Related: Learn more here about the specifications of Impack packaging's INH Box Turner.

Alright. We talked about what is the INH Box Turner, its features and benefits, its pros and cons, and who it is best suited for.

Now you’re probably asking yourself:

“How do I go about choosing the best box turner for my company?!”

Here’s how:

If you have a packer or stacker after your folder-gluer (whether an Impack or non-Impack packer/stacker), you may need a box turner.

Straight line boxes are almost always turned prior to them being packed into cases and almost never turned prior to being banded or strapped together.

Every packer or stacker requires a device to turn these boxes so as to facilitate the packing/stacking process. This device is the box turner.

👉 If you are considering the Ergosa A packer, then your 2 available options are the IN2 and the INH box turners.

Whether you choose the IN2 or INH box turner, it will get built into the Ergosa A packer and you do not need to purchase the IN2 or INH as a separate module.

The IN2 and INH are built into the Ergosa A’s conveyor to reduce cost and floor space.

👉 If you are considering the Ergosa C packer, then your 4 available options are the IN2, IN3, IN1, and INH box turners.

Almost every single Ergosa C packer is sold with an IN2 Box Turner. This IN2 is not built into the Ergosa C but instead offered as a stand-alone module.

As of 2021, the INH is becoming the more preferred option over the IN2 Box Turner as it is the most efficient option and is built into the Ergosa C packer.

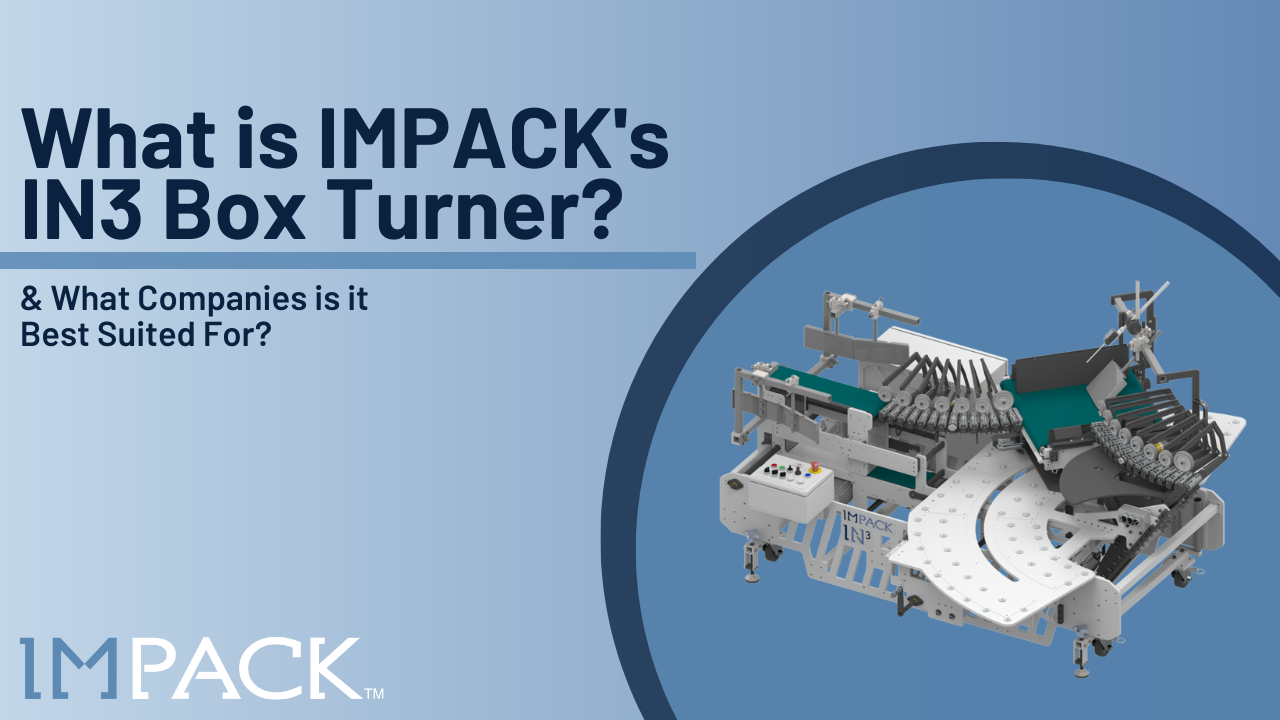

👉 If you are considering a Virtuo packer, then your 2 available options are the IN3 and IN2 box turners.

The best fit most of the time is the IN3 Box Turner — either in its standard size or the XL size depending on your production. It has the advantage of keeping the centerline from turning to a straight through setup, which is more important on an automated or fully automated line.

To reduce your costs, the IN2 is another available option but will require moving the packer if you need to switch from one orientation to the other, and this means longer setup times. But if your boxes always need turning, then the IN2 will be as fixed as an IN3.

👉 If you are considering an Everio stacker, then your 2 available options are the IN2 and IN3 box turners.

The best fit would be an IN2 in XL size.

👉 If you already have a packer or stacker (Impack or non-Impack brand) that has limitations related to case configuration due to the packer’s lack of turning capabilities, then your 3 available options are the IN3, IN180, and IN2 box turners.

To choose the best box turner for your company, follow these 3 steps:

Start by comparing the different box turning technologies on the market by reading "The Top 6 Box Turning Technologies: Which Should You Choose?"

Next, compare Impack's 5 main box turners side-by-side in the article "Comparing Impack Packaging's Box Turners: Which Is Best For Your Company?"

Finally, find out which box turner is right for your company by reading "What Box Turner is Right For You?"

If you still have questions that you need answers for, feel free to 📲 get in touch! We’d love to help answer any questions you’ve got! Plus, we’ll show you our different box turner options LIVE in action 😉.

.jpg)

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...

Are you searching for ways to improve your folder-gluer productivity and reach higher packing speeds?

.jpg)

As a box manufacturer, you most likely know that carton boxes come out of a folder-gluer in a specific orientation that is determined by the gluing...