Comparing Impack Packaging Box Turners: Which Is Best For Your Company?

If you’re thinking of adding a box turner to your gluing line, you’ve probably got lots of questions.

Are you searching for ways to improve your folder-gluer productivity and reach higher packing speeds?

If you said “Yes,” I’ve got a quick question for you:

How do you turn your boxes before packing them into cases?

Do your operators turn them by hand or is your process automated?

If automated, how automated is your process?

90% of the time, box manufacturers are forced to turn their boxes before packing them into cases.

The burden of turning boxes falls onto your packing staff.

This means:

👉 More manual labor for your packing staff.

👉 Less output and slower packing speeds.

👉 And, as a result, diminishing productivity and less business.

What if I told you that you can fully automate the turning of your boxes and allow your packing staff to fully focus on the packing...How will things change for your company?

More output, faster output, and certainly, substantial productivity gains.

All leading to more $$.

As a Mechanical Engineer and an Impack Packaging Expert for the last 4 years, I have helped dozens of box manufacturers boost their folder-gluer’s productivity.

And, no matter where I am, every floor manager asks me the same two questions:

“What is your best box turner?”

“How do I choose the right box turner for my company?”

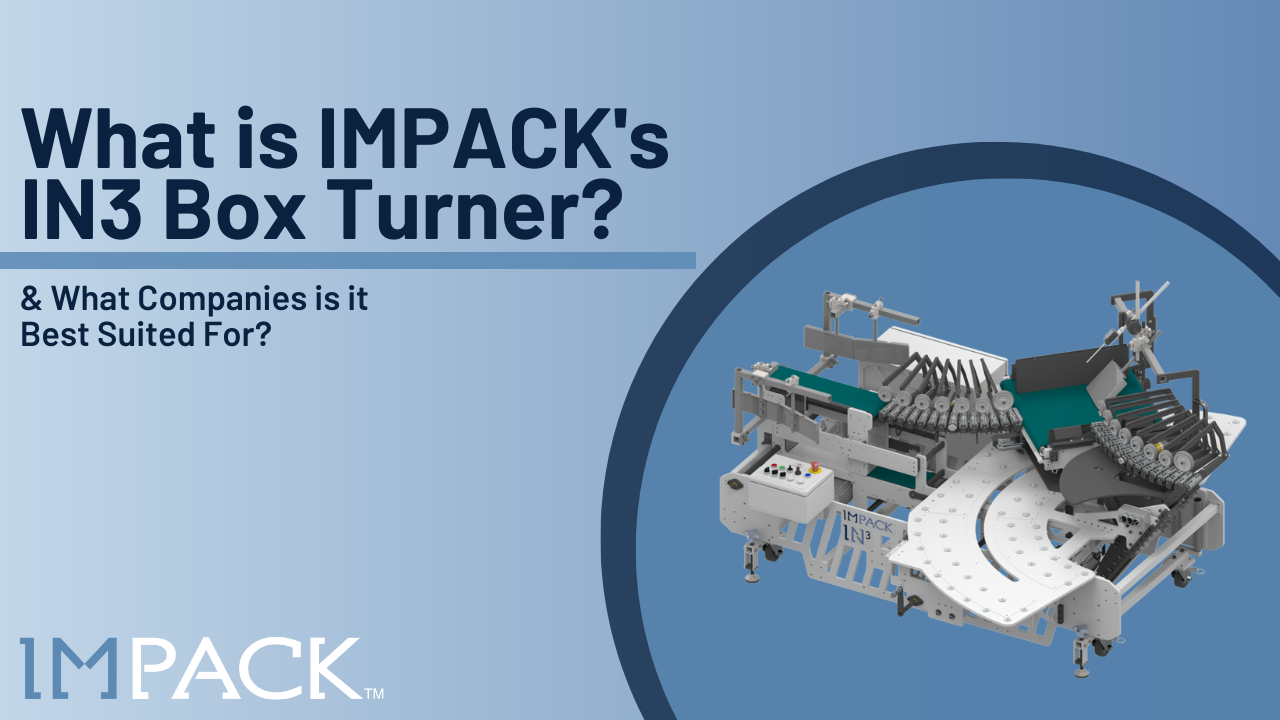

In this article, I will cover our most advanced box turner: Impack's IN3 Box Turner.

We will discuss what is the IN3 Box Turner, its pros and cons, and who it is best suited for.

This is Important: Before we dive into Impack packaging's IN3 Box Turner, if you’re not familiar with what a box turner is, learn about what is a box turner, how it works, and the benefits it offers to your packing process.

Or, if you’re already familiar with Impack packaging's IN3 Box Turner and wondering how it compares with our other box turners, check out my other article “Comparing Impack Packaging's Box Turners: Which is Best For Your Company?”

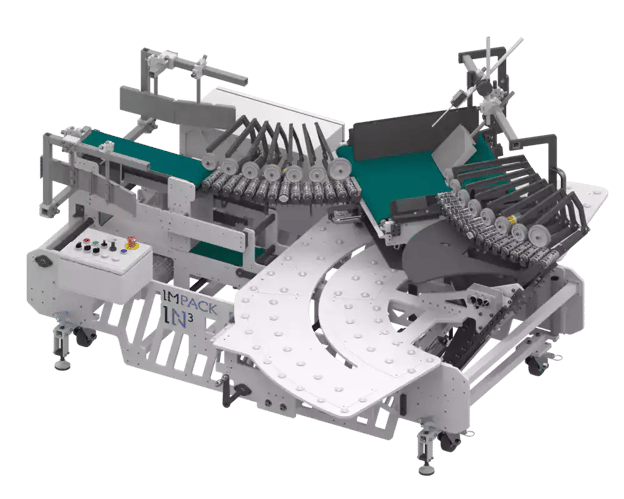

Impack packaging's IN3 Box Turner is our most advanced box turner in our IN Series.

The IN3 Box Turner remains fixed regardless of the packing mode used.

That is, the IN3 is designed to stay stationary.

No matter what turning mode or path is used, the center axis of the shingle stays on the same axis.

This allows you to avoid having to move other modules sideways when changing the turning mode.

Compatible with carton and corrugated board, the IN3 Box Turner is highly versatile and can be used with any of Impack packaging's packers or non-Impack packers.

The most advanced version in the IN box turner series.

Designed to stay stationary. No matter what path is used, it always stays at the same place so it is ideal for automatic packers like Impack packaging's Virtuo packer, Impack packaging's Everio stacker, or Bobst’s CartonPack.

Installed directly after your folder-gluer.

Offers you 3 possible turning orientations: 90° to the left, 90° to the right, and straight through.

You save on setup time since you’re not required to move any equipment paired with the IN3.

Can be paired with any of Impack's packers or non-Impack packers.

Can be paired with any of Impack's add-on modules such as the MFA Batch Inverter.

A specific version of the IN3 is available for Bobst’s CartonPack, Heidelberg's Diana Packer, and can be adapted to various other Automatic packers.

No matter what turning mode or path is used, the center axis of the shingle stays on the same axis. This means that any modules installed downstream from the IN3 Box Turner will also stay stationary. In other words, you will not need to move your equipment.

In most cases, once the IN3 Box Turner is installed with a folder-gluer packer, the whole packing system will not need to be moved. This makes setups far simpler and quicker.

More expensive and requires a larger footprint than other box turners, such as the IN1 Box Turner and IN2 Box Turner.

The folder-gluer’s kicker count is lost and therefore an auxiliary system such as Impack packaging's OBP, OBS, or INTRO would be required.

That said, the IN3 Box Turner is frequently paired with modules that manage the count independently from the folder-gluer. For example, Impack packaging's Virtuo packer, Everio stacker, MFA Batch Inverter, or Bobst’s CartonPack.

Okay. So far, we talked about what the IN3 Box Turner is, its features and benefits, and its pros and cons.

Now, you’re probably wondering whether the IN3 is a good fit for your company.

Here is the answer in the simplest and most direct way possible:

You intend to invest in an Automatic packer or a Fully-Automatic packer.

You’re considering Impack packaging's Virtuo packer, Everio stacker, or MFA Batch Inverter.

You’re considering, or already own, an Automatic packer, such as Bobst’s CartonPack, Heidelberg’s Diana Packer, and you need additional turning possibilities that are not offered by those standard automatic packers.

You do not intend to invest in an Automatic packer or a Fully-Automatic packer.

You’re considering Impack packaging's Ergosa A packer which already includes a built-in IN2 Box Turner. Hence, you would not need the IN3 Box Turner.

You’re considering Impack's Ergosa C packer, Virtuo packer, or Everio stacker and moving the modules sideways when changing the turning mode is not an issue. In this case, Impack packaging's IN2 Box Turner is a better fit.

🔍 Related: Learn more here about the specifications of Impack Packaging's IN3 Box Turner.

The IN3 Box Turner is Impack's most advanced version of our IN Series.

And it happens to be our second most popular box turner for the last 9 years (following our IN2 Box Turner).

That said, the IN3 Box Turner is not the right solution for every company.

The best choice of a box turner depends on 4 key factors:

The size of boxes that you produce.

Your product mix, range, and variety.

The amount of floor space you have available.

And the type of folder-gluer packer or stacker that you choose.

So, what box turner is best for your company?

To choose the best fitting box turner for your company’s needs, budget, and production, follow these steps:

Begin by comparing the different box turning technologies on the market by reading "The Top 6 Box Turning Technologies: Which Should You Choose?"

Next, compare Impack's 5 main box turners side-by-side in the article "Comparing Impack Packaging's Box Turners: Which Is Best For Your Company?"

Then, find out which box turner is right for your company by reading "What Box Turner is Right For You?"

👉 If you’ve got more questions specific to your company, get in touch! We’ll be more than happy to answer all your questions!

👉 Or, if you’re ready to choose a box turner for your company, schedule an appointment with an Impack Expert and we’ll show you some of our box turners LIVE in action! PS: No commitment required.

.jpg)

If you’re thinking of adding a box turner to your gluing line, you’ve probably got lots of questions.

.jpg)

As a box manufacturer, you most likely know that carton boxes come out of a folder-gluer in a specific orientation that is determined by the gluing...

.jpg)

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with...