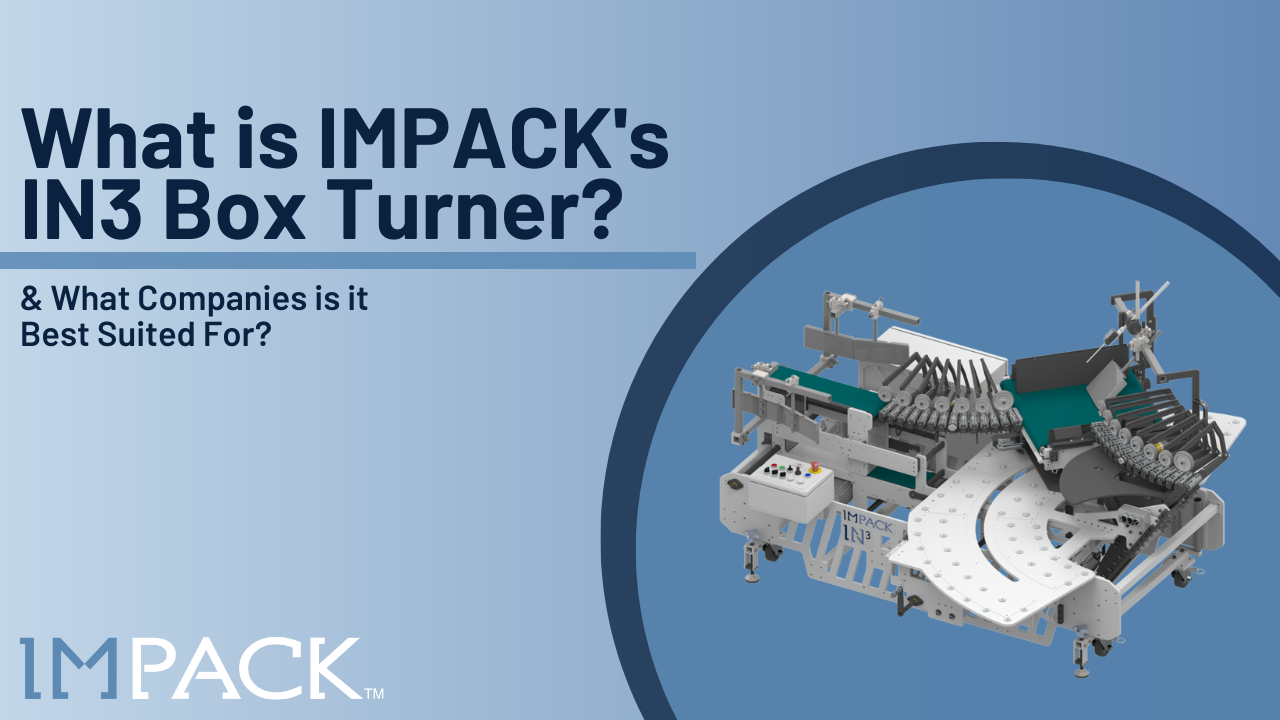

What is Impack Packaging's IN3 Box Turner?

Are you searching for ways to improve your folder-gluer productivity and reach higher packing speeds?

11 min read

Stefan Badertscher

:

January 14, 2022

Stefan Badertscher

:

January 14, 2022

.jpg)

If you’re considering the purchase of Impack packaging's Ergosa packer, you’re probably debating what Box Turner you should choose to be paired with your Ergosa packer.

The IN1, IN2, IN3, IN180, and INH Box Turners are all possible options that you can pair with your Ergosa packer.

But each of these options vary drastically in their price, size, specs, and features, so it can often be hard to choose between those different options, especially if you’re not sure what features are important to your production.

The INH Box Turner is our newest innovation that offers the latest and most advanced box turning technology on the market.

It offers features and capabilities that all the other Impack Box Turners do not and cannot offer.

As such, every time I am discussing a project with a box manufacturer, they always ask me those same questions:

“What makes the INH Box Turner Different?”

“How does it compare to the other box turners?”

“And is the INH really worth the extra cost?!”

This article will review Impack's INH Box Turner in the most objective and unbiased way possible.

We will start by comparing the most popular packing systems on the market, assess them on their pros and cons, and then talk about the design, specs, pros and cons, and features of the INH.

By the end of this article you’ll know exactly whether the INH Box Turner is the right choice for you or whether you should go for a different option.

The INH Box Turner is Impack's newest box turner (patented) with the most advanced box turning technology on the market.

🔍 Recommended: If you’re not familiar with what a box turner is, and the benefits it can provide to your packing process, read the article “What is a Box Turner and Do I Really Need One?” before diving into this article!

What makes the INH different from all the other box turners is that it is one of the only box turner in the world that can turn your boxes 90° while keeping your folder-gluer packer in alignment with your folder-gluer.

This means that none of your equipment will have to be positioned sideways or angled 90° to the left or right.

Your boxes will continue in the gluing direction of the folder-gluer and the equipment will not require any additional lateral space.

Because the INH Box Turner can be installed directly after your folder-gluer’s delivery belt with an Impack packaging Ergosa packer, it is the most compact helicoidal turner in the world.

By accumulating the boxes on their edge, it reduces the shingle speed to the minimum possible speed at the packing station, thus giving your operators plenty of time to pack the boxes efficiently.

🔍 Recommended: If you’re still new to learning about Impack packaging's INH Box Turner and you’d like to learn about its pros and cons and what companies it is best suited for, check out the article “What is the INH Box Turner & What Companies is it Best Suited For?”

The best way for you to find out whether the INH Box Turner is worth investing in or not is by comparing the most popular solutions on the market and assessing their pros and cons against one another.

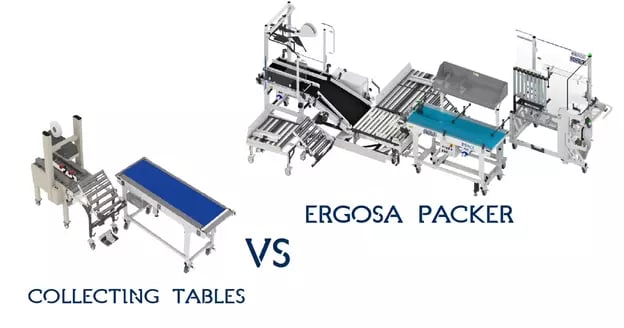

So, let’s evaluate the pros and cons of the two most popular packing systems on the market: Collecting Tables and Folder-Gluer Packers.

Collecting Tables are pick and place stations otherwise known as “Packing Help” or “Packing Aid” that present the boxes in a better way for your packing staff to pack the boxes into the case.

Although many packaging equipment suppliers refer to their traditional Collecting Tables as “packers” or “right-angle packers,” those systems are — in the end — just box turners.

And this is not based on opinion but strictly on the evaluation of their technical working principles i.e. the way those machines operate and their features and capabilities.

Collecting Tables simply present the boxes in a better way for your operators to pack the boxes into the case which is exactly what a box turner does and is built to do.

Collecting Tables do not automate your case packing process and have no automation of any form. Instead, they serve as a packing help/aid to the traditional manual packing process.

And this is why we’re comparing Collecting Tables to Folder-Gluer Packers. It is not a question of which is better but more so whether you need a box turner in the first place:

A Collecting Table is a box turner. A folder-gluer packer, on the other hand, is a fully-fledged packing system that includes a box turner.

Examples of the most common Collecting Tables in Western countries are Bobst’s Handypack GT, KBA Duran’s Omega Pack Station, Tünkers FAS480, and Vega Group’s Pack 44S.

Impack packaging's Collecting Tables are the “Packing Help Stations.”

Let’s examine the pros and cons of Collecting Tables:

|

Pros |

Cons |

|

Presents the boxes in a better way to facilitate an easier packing process |

Case packing is 100% manual and involves lifting partial rows or full rows when possible (as much as each packing person's hands can carry per movement) |

|

Allows you to turn your boxes in a helicoidal pattern hence keeping the count from the folder-gluer’s kicker |

You need a separate tilting table for the case packing process |

|

The box accumulation is nearly vertical which allows for optimal accumulation density |

There is no possible way to automatically transfer filled cases to an Automatic Case Sealer |

|

The accumulation conveyor added must be configured perpendicular to the folder-gluer which takes up a lot of extra lateral space |

|

|

Offers only 1 packing mode: Hand-packing of limited batches of boxes |

|

|

Some non-straight line boxes cannot be processed and the Collecting Table must be set aside |

|

|

No case management is involved: Packing staff must do the case flap closing, taping, and ejecting fully manually |

A folder-gluer packer is a packing system that utilizes a modernized packing technology to allow you to dramatically improve the efficiency, ergonomy, and productivity of how you pack your boxes into cases by offering you automated case management capabilities.

In contrast to Collecting Tables, a folder-gluer packer is a fully-fledged packing system that includes a box turner and several other modules to automate your entire packing process.

And, unlike Collecting Tables which are manual, folder-gluer packers come in 3 different levels of automation: Semi-Automatic, Automatic, and Fully-Automatic.

In other words, folder-gluer packers automate actions in your case packing process to help you reduce your packing staff, cut down on costs, improve ergonomics, and produce more output, faster.

🔍 Recommended: Feeling unsure about what level of automation your company needs? Find out the right level of automation for your production by reading “What’s the Difference between Manual, Semi-Auto, Auto & Fully-Auto Folder-Gluer Packers?”

Examples of the most common folder-gluer packers in Western countries are Bobst’s CartonPack 4, Heidelberg’s Diana Packer, WSI Global’s Express Pack, and Graphic West Packaging’s J-Pack.

Impack packaging's packers are the Ergosa Semi-Automatic packer, Virtuo Automatic packer, and the Virtuo + ACF Fully-Automatic packer.

🔍 Recommended:

To learn more about Impack packaging's Ergosa packer, its features and benefits, and what types of boxes it is best suited for, check out “What is the Ergosa Packer & How Can It Improve My Packing Process?”

To learn more about Impack packaging's Virtuo packer, its features and benefits, and what types of boxes it is best suited for, check out “What is the Virtuo Packer & What Companies is the Virtuo Best Suited For?”

Given that Collecting Tables are manual machines, it would only be fair to compare them to machines in the same category or similar categories.

As for machines in the same category, all the other popular machines within the manual category are, in the end, Collecting Tables that are very similar to Bobst’s Handypack GT, KBA Duran’s Omega Pack Station, Tünkers FAS480, and Vega Group’s Pack 44S.

As for similar categories, the Semi-Automatic category is the next level of automation right above the manual category. And the Ergosa packer is the only machine that exists on the market, to date, that can be classified as a Semi-Automatic packer.

As such, we will use the Ergosa packer as an example to demonstrate when the INH Box Turner is a must-have for your production.

There are 2 different versions of the Ergosa packer: The Ergosa A and the Ergosa C.

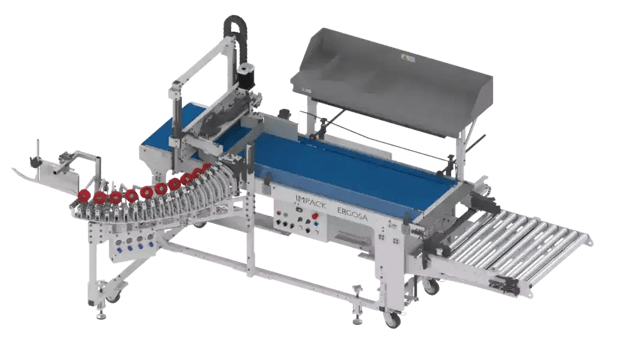

The standard Ergosa and box turner configurations are: 1) Ergosa A with a built-in IN2 Box Turner and 2) Ergosa C with a stand-alone IN2 Box Turner.

Let’s examine the pros and cons of the Ergosa A/C and IN2 Box Turner combinations:

|

Pros |

Cons |

|

Not only facilitates an easier packing process, but also, improves ergonomics, reduces your number of operators/packing staff, cuts down on costs, increases productivity, and boosts packing speeds |

Because the boxes are turned with a right angle transfer, the count is lost from the folder-gluer’s kicker. Therefore, an optical brightener marking system must be used to detect the count underneath a UV blacklight* |

|

No lifting of loads is required. The Ergosa semi-automates your packing process so that you can pack a complete row of boxes, in one single movement, into the case |

Boxes must be raised to get optimal accumulation density. This is very easy but it does mean additional time is required in the overall case time cycle. This additional time is less than 1 second but it does mean less cases per hour. |

|

Tilting table and Case Holding System included. No additional purchases needed |

|

|

Cases are automatically transferred to the Automatic Case Sealer |

|

|

Offers both linear and angled configurations allowing you to easily adapt to your existing floor space |

|

|

Offers 3 main packing modes: Horizontal Mode, Vertical Mode (Ergosa C only), and Pick & Place (or Manual Mode). Additional packing modes are also available for very small boxes and for banding/strapping machines with the Ergosa C. |

|

|

Straight line boxes are handled with the Horizontal Mode allowing sliding of full rows into cases without lifting. 50-100% faster than Collecting Tables |

|

|

Other types of boxes can be handled with either the Vertical Mode (only offered with the Ergosa C) or Pick & Place (or Manual Mode) |

|

|

Includes automated case management, fully automated flap closing or flap holding, and fully automated case ejection |

*Very important note: Although the count from the folder-gluer’s kicker is lost with the Ergosa packer and IN2 Box Turner combination, this is not considered a problem for most box manufacturers. This is simply because the optical brightener is used instead to detect the count.

The optical brightener dilutes 340 to 1 in clear water so it is not harmful as per its MSDS and does not damage your client’s boxes.

It is no stranger to packing boxes since it is used as a bleaching agent in the carton-making process. That said, and in the spirit of being as unbiased as possible, we listed it as a “con” as it could be considered as a “disadvantage” against the other solutions that are keeping the box count after turning the boxes.

🔍 Recommended: If you’re feeling unsure about whether you should invest in a Collecting Table like Bobst’s Handypack GT or a Folder-Gluer Packer like Impack's Ergosa, I strongly recommend you to:

Read “What's the Difference between Collecting Tables and the Ergosa Packer?” to find out the key differences between Collecting Tables and the Ergosa packer.

And then Compare Collecting Tables Versus the Ergosa Packer to find out which solution is best for your company.

Now that you have a better idea about the pros and cons of a Collecting Table (a box turner) versus a Folder-Gluer Packer (a fully equipped packing system), you’re probably wondering whether you need the INH Box Turner and under what circumstances it is worth investing in.

Here’s the answer in the simplest way possible: If you’re interested in the Ergosa packer but you do not want to lose the count from your folder-gluer’s kicker, and prefer not to use an optical brightener, this is where the INH Box Turner becomes the ideal solution.

You see, Impack packaging's Ergosa A packer already includes a built-in box turner which is the IN2 Box Turner as it is the most cost-effective solution for box turning.

However, as of 2021, the INH Box Turner is becoming the top chosen built-in box turner with the Ergosa A packer instead of the IN2 Box Turner.

As for the Ergosa C packer, it is most often sold with a stand-alone IN2 Box Turner (purchased separately).

But, there is an exception: When the Ergosa C packer is sold with an INH Box Turner, the INH is built into the Ergosa C.

In other words, if you’re considering the Ergosa A, you have the option of choosing from the IN2 or INH box turners to be built into the Ergosa A. No additional purchases needed.

Or, if you’re considering the Ergosa C, you have the option of choosing either a stand-alone IN2 Box Turner (purchased separately) or a built-in INH Box Turner (no additional purchases needed).

The Ergosa A — INH and the Ergosa C — INH combinations are the 2 most efficient and versatile Semi-Automatic packers offered by IMPACK.

🔍 Recommended: Learn more here about the specifications of Impack Packaging's different box turners.

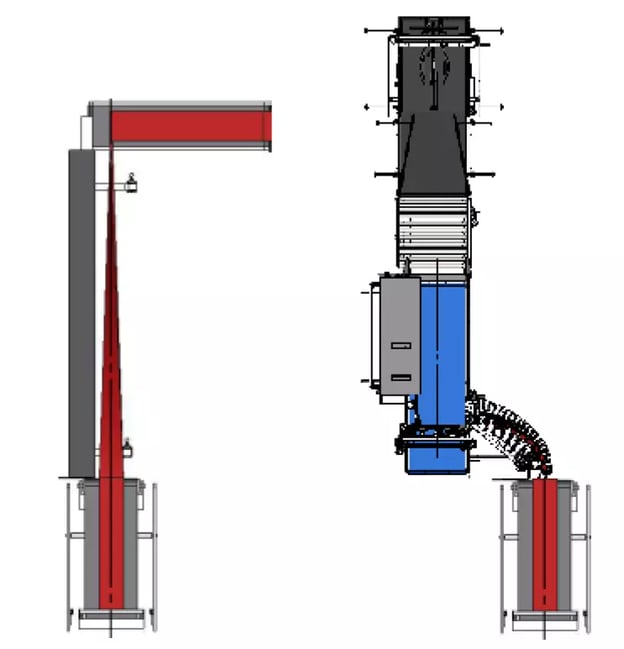

The INH Box Turner is far more compact than Collecting Tables.

In fact, it is almost as compact as Impack packaging's IN2 Box Turner and does not require the accumulation conveyor to be perpendicular to the box flow but instead, it can either be perpendicular to the box flow or linear to the box flow.

The INH Box Turner is designed as such that your boxes will continue in the gluing direction of your folder-gluer and none of your equipment will have to be positioned sideways or angled 90° to the left or right.

If you’re processing non-straight line boxes, you would have to discard your Collecting Table because it just cannot handle more complex boxes.

In contrast, when using the Ergosa - IN2 or INH combination, you never have to set aside the entire machine because you can simply switch to a different packing mode that can handle those more complex types of boxes.

This means that you save precious floor space and time in the overall cycle that is otherwise spent on shutting down the full machine and switching to another machine.

The image below shows a traditional Collecting Table (on the left) versus Impack's Ergosa packer and INH combination with a straight conveyor (on the right):

As you can see in the diagram above, the Collecting Table offers a manual tilting station and it requires a manual transfer. The Ergosa - INH combination has a case conveyor where the end of the case conveyor is connected with the client's case sealer and the transfer is done fully automatically with either flap holding or automatic flap folding.

Integrated to the Ergosa packer.

Dimension of 1m x 1m (no additional length to the Ergosa Packer).

Processes carton boxes only.

Box dimensions:

Width: 100 to 495mm (4 to 19.5 in.)

Length: 125 to 495mm (5 to 19.5 in.)

Turns the shingle and the boxes by 90°, keeps the kicker count visible, and accumulates boxes on their edge.

Keeps the count from the folder-gluer’s kicker without using an optical brightener.

Just like the IN2 Box Turner, the INH Box Turner is a very compact box turner when compared to Collecting Tables that have a helicoidal section, such as Bobst's Handypack GT and other similar Collecting Tables on the market.

Just like the IN2 Box Turner, the INH Box Turner allows your boxes to continue in the gluing direction of the folder-gluer and your equipment will not require additional lateral space. In contrast, Collecting Tables have a helicoidal section which always turns the boxes 90° hence requiring additional lateral space.

The INH Box Turner is not compatible with all boxes made of corrugated board. Some boxes may be damaged by the helicoidal path that is exposing them to torsion.

Impack's newest innovation with the latest box turning technology on the market.

Keeps the count from the folder-gluer’s kicker.

Compatible with small to medium-sized boxes.

Installed directly after the folder-gluer’s delivery belt with Impack's Ergosa packer.

Offers you 2 possible turning orientations: 90° or straight through.

The most compact of all helicoidal turners on the market.

Allows you to accumulate boxes on their edge and maximize the density of the accumulated boxes. This means more boxes per meter of conveyor.

The answer is yes and no.

For some companies, the INH is the perfect solution to maximizing their folder-gluer’s productivity and boosting their packing speeds.

But for others, it might be the wrong fit or there might be better solutions out there.

At Impack packaging, we never shy away from being 100% transparent about what our machines can do, what they cannot do, and when they are right fits versus when you’re better off going to a competitor.

So, here is your answer in less than 50 seconds ⏱️:

You intend to invest in a Semi-Automatic packer.

Marking boxes with an optical brightener is an issue for your company or your customer.

You want to facilitate an easier packing process for your operators that are using manual packing stations by turning your boxes 90°.

Boosting your folder-gluer productivity and reaching higher packing speeds are your top priorities.

You are processing a large percentage of straight line boxes made of folding carton.

You do not intend to invest in a Semi-Automatic packer. Instead, you intend to invest in an Automatic, a Fully-Automatic packer, or a Collecting Table.

Marking boxes with an optical brightener is not an issue for your company or your customer and you're not looking for the most advanced box turner on the market. Here, Impack's IN1 Box Turner or IN2 Box Turner could be better options.

Boosting your folder-gluer productivity and reaching higher packing speeds are not your top priorities.

You are not processing a large percentage of straight line boxes.

You want to process corrugated board or micro-flute boxes.

If you’re still unsure about whether you should invest in a Collecting Table or a Folder-Gluer Packer, get your answer by reading “What's the Difference between Collecting Tables and the Ergosa Packer?”

Next, to ensure that you’re selecting the best box turner for your packer, compare Impack's 5 main box turners side-by-side.

Then, discover which box turner is right for your company by reading "What Box Turner is Right For You?"

And finally, find out how much the different box turners cost by checking out “How Much Does a Box Turner Cost?” (Coming Soon).

If you still have questions that you need answers for, feel free to 📲get in touch! We’d love to help answer any questions you’ve got! Plus, we’ll show you our different box turner options LIVE in action 😉.

Are you searching for ways to improve your folder-gluer productivity and reach higher packing speeds?

.jpg)

As a box manufacturer, you most likely know that carton boxes come out of a folder-gluer in a specific orientation that is determined by the gluing...

If you’re thinking of adding a box turner to your gluing line, you’re probably asking yourself: