Is the MFA Batch Inverter Right for Your Company?

If you find yourself here, then you’ve probably been scouring the internet looking to find a way to increase your automatic bottom box production,...

The two most common methods used for stacking are banding and strapping.

While these terms are sometimes used interchangeably, there are differences between them, particularly in the box-making industry.

Banding and strapping involve bundling products together, but the methods and materials used can vary.

You may be asking yourself:

How do I know whether I should band my boxes, or strap my boxes?

It is important to note that the definitions and applications of banding and strapping may differ in other industries.

However, in the box-making industry, the choice between banding and strapping is made based on the type of box being produced and the needs of the end users.

In this article, we will explore what banding and strapping are, and their advantages, and we will examine whether it’s the best solution for your company.

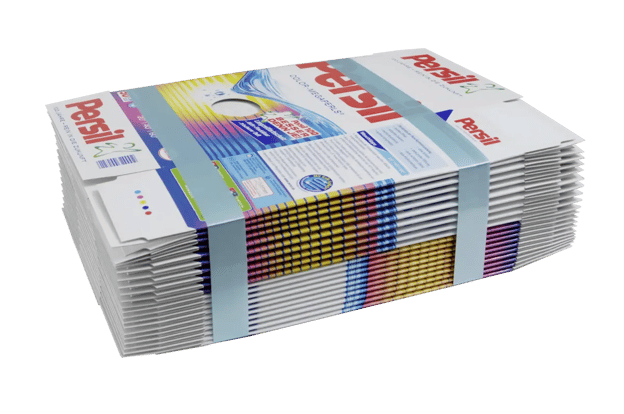

In the box-making industry, boxes are typically bundled and wrapped with bandroles before being put into cases or onto pallets.

Banding and strapping can both be used, but the choice depends on the type of box being produced and the needs of the end users.

In general, banding is more appropriate for carton board boxes, particularly those with high-quality printing.

Carton board boxes are often used for high-end products, and banding is preferred as it minimizes the risk of damaging the box's surface.

On the other hand, corrugated boxes are typically used as the outside package and are stronger and more durable. Therefore, strapping is often used for corrugated boxes.

Overall, while banding and strapping share similarities in terms of bundling products, the materials used, and methods applied can vary depending on the industry and specific needs.

When it comes to banding and strapping, the width and material of the bands can make a big difference in their effectiveness.

The most commonly suggested bandwidth for bundling products is between 20 to 60 mm.

Additionally, the most used materials for banding are brown and white paper and polypropylene (PP), while strapping is typically done with polyester (PET) or polypropylene (PP) bands that are narrower than those used in banding.

It's important to note that the width of the bands can have an impact on the pressure applied to the boxes being bundled.

Generally, the wider the band, the more widespread the pressure will be applied across the band, easing the pressure upon the bundled boxes, particularly to the boxes at the top and bottom of the bundle.

In some cases, strapping can even cause damage to the boxes.

For this reason, if the end-user has high-quality or fragile products that require special handling, it is generally better to choose banding over strapping.

In summary, the choice between banding and strapping depends on a variety of factors, including the width and material of the bands, the specific needs of the end-user, and preserving the quality of the bundled boxes.

Understanding these differences can help ensure that products are bundled in the most effective and safe manner possible.

When it comes to sealing bandroles, there are two methods commonly used: ultrasonic and hot wedge.

Both methods can be used for both banding and strapping, but for high-quality boxes, ultrasonic sealing is recommended over hot wedge.

This is because the hot wedge method still poses a risk of damaging the box.

It's worth noting that while generally banding can be easily opened by hand, strapping typically requires a tool such as scissors or a knife to be opened.

Operators must be careful when using these tools, as they can potentially damage the box surface. Additionally, opening strapped boxes can be a time-consuming process.

Making the choice between banding your boxes or strapping them is a question of quality assurance and cost-effectiveness.

Generally, bands are more expensive than straps.

Banding is s better solution for your company if:

Strapping is a better solution for your company if:

If you want to learn more about packaging tips on how to preserve your boxes while also looking for the best packaging equipment for your company, read the following articles.

Can Impack’s Machines Damage My Boxes?

What Are Folder-Gluer Packaging Equipment & Which Machine is Best For You?

Top 10 Frequently Asked Questions About Impack’s Packaging Equipment

-1.jpg)

If you find yourself here, then you’ve probably been scouring the internet looking to find a way to increase your automatic bottom box production,...

If you’re thinking of adding a box turner to your gluing line, you’re probably asking yourself:

.jpg)

As a box manufacturer, you most likely know that carton boxes come out of a folder-gluer in a specific orientation that is determined by the gluing...