ERGOSA

Modular Semi-Automatic Packing Solution

Fast. Flexible. Ergonomic.

Reduce Manual Labor

30-100% Increase in Folder-Gluer Productivity

Achieve ROI Within 1 Year

The most versatile packer for folder-gluers on the market! The Ergosa is a modular semi-automatic packing system configured to fit your product mix. It is customizable and expandable to fit your production now and the future.

Best for Folding Carton Board

The ERGOSA is optimized for small to medium size folding carton packaging.

While you could run corrugated through the Ergosa, the Virtuo is better suited for these heavier boxes. If you have more than one folder-gluer you can optimize your production by processing medium to large corrugated packaging on one finishing line outfitted with a Virtuo and run all other box types on a finishing line outfitted with an ERGOSA.

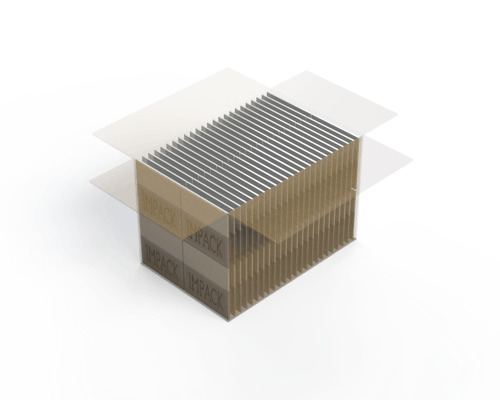

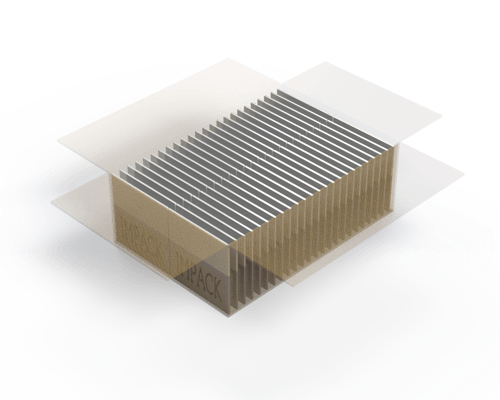

4-6 Cases per Minute

Multi-Row, Multi-Layer Case Configuration in Horizontal and Hand Packing Modes

Multi-Row Case Configuration in Vertical Packing Mode

Pack any box type!

Configurable for any box type - straight-line, auto-bottom, 4 & 6 corner

Case Compatibility

Boxes can be packed into open top cases or standard cases with flaps.

Modular Packing Solution

The Ergosa’s magic is in it’s modularity, allowing us to configure the machine to fit your exact production needs. Buy only the modules you need. We offer a clear upgrade path so that the system can evolve with your business and production.

The ERGOSA has modules and special tooling for each box type, making it a flexible solution for packaging producers with a variety of box types in their product mix.

Thoughtful Engineering

Not just an accumulation conveyor! IMPACK has been designing machines with the operator in mind for over 20 years. The design, location and usability of each component reflects years of analyzing the way personnel work, pack and interact with the system.

Horizontal Packing Mode

Ergonomic horizontal slide packing for small to medium straight-line & small 4/6 corner boxes

Vertical Packing Mode

Button triggered vertical push packing of medium to large straight-line & 4/6 corner boxes

Backup Hand Packing Mode

Single or dual operator hand packing of complex and very small box types

The Case Management system comes with an integrated hand packing station on the back side for those tricky box types. The front of the horizontal case dock has locking connections for a second hand packing module dual hand packing mode accommodates 2 operators and allows you to double hand packing speed.

In manual hand packing mode the case management system take boxes from the two hand packing stations and brings them to a single conveyor with it’s bump and turn function. The rising conveyor brings the cases through the flap folder module in preparation for a 3rd party case sealer.

The case management system with integrated flap folder give you an additional 10-20% increase in performance compared to competitor packing stations.

Your ERGOSA can include smart tooling for trays and tiny boxes.

Fast Easy Setup and Changeover

3-7 Minute Changeovers Between Modes

The Ergosa is easy to use and requires minimal tools. Current packing personnel can be trained in 3 days to operate the Ergosa and do changeovers.

Paired with the Patented INH Box Turner

All ERGOSA solutions start with an accumulation conveyor and a box turner for shingle re-orientation. The standard ERGOSA configuration features an integrated INH box turner — the most powerful and versatile box turner you can get. The patented INH is an ultra compact helical box turner that allows you to re-orient your shingle for optimal case configuration without losing the kicker count.

Find out more about the INH box turner here.

ERGOSA Specs:

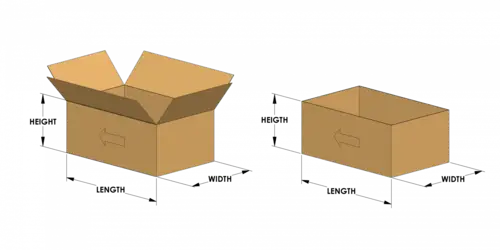

RSC and HSC Case Dimensions

28 in

30 in

15 in

4.5 in

6 in

4 in

22 in

26 in

19.5 in

4.5 in

14 in

4 in

22 in

27 in

19.5 in

8 in

10 in

5 in

Box Dimensions

24 in

24 in

1 in

3 in

25.5 in

25.5 in

0 in

0 in

19.5 in

22.5 in

11 in

4.75 in

4 in

5.5 in

Ergosa Dimensions

186 in

54 in

67.5 in