Is the MFA Batch Inverter Right for Your Company?

If you find yourself here, then you’ve probably been scouring the internet looking to find a way to increase your automatic bottom box production,...

2 min read

Maxime Jacques

:

March 23, 2023

Maxime Jacques

:

March 23, 2023

In this article, we will define what an MFA batch inverter is, its limits, and its prerequisites to meet your goals.

Let's begin by defining what an MFA batch inverter is.

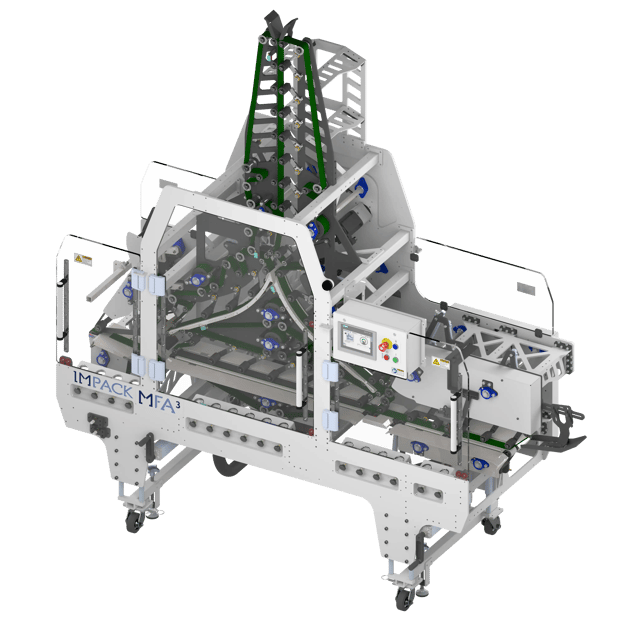

An MFA batch inverter is a machine that automatically inverts batches of boxes, head to tail, from a predetermined number of boxes.

Firstly, the MFA is not a packer. It is a pre-packing module for preparing the shingle, i.e. the boxes, for packing.

Therefore, when purchasing an MFA, you’ll need to purchase a packer and, in some cases, a box turner such as the IN3.

Secondly, the MFA is an automatic system.

Meaning, adding an MFA to your folding gluing line requires all the necessary prerequisites for an automatic solution to work properly and be profitable in the long run.

So, let’s explore what the MFA does.

As the MFA inverts batches of boxes, it also counts and separates the shingle of boxes into batches.

Once separated, one of the batches will pass through without being inverted, while the second batch gets inverted.

Finally, at the exit of the machine, both batches merge into a new shingle.

Additionally, the MFA is intended only for folding carton boxes.

Because of its curvy internal structure, it cannot process corrugated boxes without damaging them. It is therefore only suitable for folding carton boxes.

Its primary purpose is to invert the crash-lock bottom folding carton boxes in order to prepare them for packing.

With an MFA, it is no longer up to the operator to perform the inversion operation manually.

Like all Impack machines, the MFA has 2 modes: an Inversion mode for crash-lock bottom boxes, and a Straight-Line mode for all your other boxes that do not require the inversion.

And this is very useful because 100% of your production is not necessarily crash-lock bottom boxes.

This straight-through mode still keeps the MFA’s box counting and separating functions, however, which facilitates the packing process.

In the field of folding cartons, the MFA is a very high-tech solution, but as we have seen it is a system made for the preparation of the shingle, it is not a packer in itself.

It is therefore necessary to couple it with a packer.

Nonetheless, we want to make sure to match the MFA with a packer that won’t strip the MFA from its perks.

For the MFA, the packaging solution is the Ergosa C in Vertical mode, which is a semi-automatic solution.

Although the MFA is an automatic machine, after pairing it with Impack’s Virtuo automatic folder-gluer packer, we’ve concluded that the complexity of these two machines paired together may not always prove to be optimal.

The Ergosa C is by far the best folder-gluer packer to pair the MFA with.

🔍 Related: Watch this amazing video of the MFA where an operator packs nearly 50,000 boxes per hour, a near-impossible feat incredible to watch!

Although MFA projects may be complex at first, their addition to your folder-gluer line will drastically change your productivity levels.

Nevertheless, we can guarantee that you need an MFA if:

On the other hand, the MFA Batch Inverter may not be the right solution for you if:

If you want to learn more about the MFA, specifications on the boxes it can run, and the compatible folder-gluer packers you can pair it with, read the following articles:

What are the Limitations of the MFA-Ergosa C Vertical Mode? (coming soon)

What is the MFA Inversion: Everything You Need to Know (coming soon)

What is the Ergosa C’s Vertical Mode and What Production is it Best Suited For?

-1.jpg)

If you find yourself here, then you’ve probably been scouring the internet looking to find a way to increase your automatic bottom box production,...

Adding a box turner to the end of your folding-gluing line is almost always essential.

Are you currently looking to purchase a new folder-gluer packer or a folder-gluer stacker?