What is Impack Packaging's IN1 Box Turner?

If you’re thinking of adding a box turner to your gluing line, you’re probably asking yourself:

.jpg)

As a box manufacturer, you most likely know that carton boxes come out of a folder-gluer in a specific orientation that is determined by the gluing process.

Unfortunately, in most cases, this orientation is not the same orientation at which you’d want to pack your boxes into cases to meet your customer’s requirements or best practices.

Therefore, 90% of box manufacturers need to turn their boxes before packing them into cases.

The burden of turning the boxes falls onto your operators or packing staff.

This means:

👉 More manual labor for your operators or packing staff.

👉 Slower packing speeds and diminishing productivity.

👉 Less ergonomic workstations and greater repetitive strain injuries for your operators/packing staff.

What if I told you that you can fully automate the turning of your boxes so that you never have to worry about it ever again?

“How?”

By adding a box turner to your gluing line.

As an Impack Packaging Mechanical Engineerand an Area Sales Manager for the last 4 years, I have recommended, tested, and administered the installation and training of dozens of box turners.

Two weeks ago, I talked about what is a box turner, its purpose, and who actually needs one.

Last week, I dove into comparing Impack packaging's 5 main box turners against one another so that you can know exactly which box turner is right for you.

This article will cover Impack packaging's IN2 Box Turner: What it is, its pros and cons, and who it is best suited for.

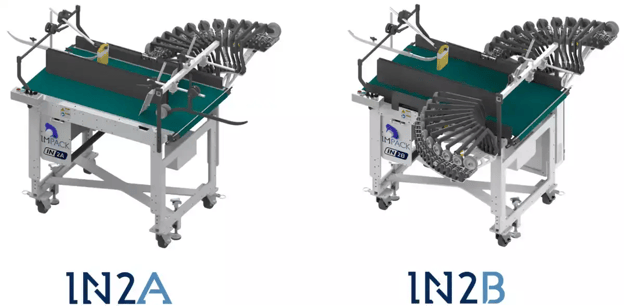

Impack packaging's IN2 Box Turner is our top sold and most popular box turner that is available in 2 main versions: The “IN2A” and the “IN2B.”

The IN2A version offers only 1 turning branch (either left turning or right turning) whereas the IN2B version offers 2 turning branches (both left turning and right turning).

Both versions can be installed onto your folder-gluer packer and both can be controlled directly by Impack's Ergosa packer, Virtuo packer, or independently.

🔍 Related: Wondering what packing systems does Impack packaging offer? Learn about Impack's 3 Main Machines & Which Machine is Right For You?

Compatible with carton and corrugated board, the IN2 Box Turner self-adjusts and can be used with any of Impack packaging's packers.

It is noteworthy to mention that Impack's Ergosa A packer already includes a built-in box turner.

This built-in box turner is most often the IN2 Box Turner (or more recently the INH Box Turner is also becoming another popular option to be built into the Ergosa A packer instead of the IN2).

In other words, the IN2 Box Turner is almost always included as part of the Ergosa A package. No additional box turner purchases are needed.

The INH Box Turner is our newest innovation that offers the most advanced box turning technology on the market.

The INH can be built into the Ergosa A packer (instead of the IN2) and the Ergosa C packer.

When handling straight line boxes, The INH is the most efficient and best-fitting box turner for the Ergosa A and Ergosa C packers.

That said, it is not as versatile as the IN2 just yet in terms of handling non-straight line boxes.

We also offer an optional IN2XS add-on module that can be retrofitted on the IN2A or IN2B box turners to facilitate the turning of narrow boxes.

Impack's top sold and most popular box turner that is available in 2 versions: The IN2A and the IN2B.

An easy, simple, and very economical box turner. Also, one of the most compact box turners on the market alongside the IN1 Box Turner.

Compatible with small to medium-sized boxes.

Installed directly after your folder-gluer.

The IN2A offers you 2 possible turning orientations: The first orientation is 90° to the left or 90° to the right (you get to choose only 1 of the 2 orientations when ordering). The second orientation is straight through.

The IN2B offers you 3 possible turning orientations: 90° to the left, 90° to the right, and straight through.

Very Compact: The IN2 Box Turner is a very compact box turner when compared to Collecting Tables that have a Helicoidal section, such as Bobst's Handypack GT and other similar Collecting Tables on the market.

The IN2 Box Turner allows your boxes to continue in the gluing direction of the folder-gluer and your equipment will not require additional lateral space. In contrast, Collecting Tables have a Helicoidal section which always turns the boxes 90° hence requiring additional lateral space.

The IN2 Box Turner is compatible with almost all types of boxes and both folding carton and corrugated board.

The folder-gluer’s kicker count is lost and therefore an auxiliary system such as Impack Packaging's OBP should be used with an overhead UV light.

The IN2 Box Turner must be moved sideways depending on what turning mode is used (which is super easy but part of the setup process). This is the same for any equipment installed downstream of the IN2 Box Turner.

For some companies, the IN2 Box Turner is the perfect fit.

But for others, it might be the wrong fit or there might be better solutions out there.

For the last 17 years, the IN2 has been Impack's top chosen box turner.

But, at Impack packaging, we understand that the IN2 is not the right solution for each and every company.

After all, we’re a team of engineers.

And we get that a solution either works or it doesn’t.

That’s just the reality.

“So, what companies is the IN2 Box Turner best suited for?”

Here is the answer you’ve been waiting for in under 30 seconds ⏱️:

You intend to invest in a Semi-Automatic packer or Fully-Automatic packer.

Boosting your folder-gluer productivity and reaching higher packing speeds are your top priorities.

Marking boxes with an optical brightener is not an issue for your company.

You process mainly overstack shingles with a large percentage of straight line boxes.

You do not intend to invest in a Semi-Automatic packer or Fully-Automatic packer.

Boosting your folder-gluer productivity and reaching higher packing speeds are not your top priorities.

Marking boxes with an optical brightener is an issue for your company.

You process a large percentage of understack shingles (Understack shingles cannot be turned with the IN2 Box Turner).

You have big boxes that are causing interlock issues and preventing them from turning.

🔍 Related: Learn more here about the specifications of Impack Packaging's IN2 Box Turner.

Alright. We talked about what is the IN2 Box Turner, its features and benefits, its pros and cons, and who it is best suited for.

Now you’re probably asking yourself:

“How does the IN2 compare to the other box turners?”

“And how do I know which box turner is right for me?”

I’ve got you covered 😉!

To choose the best fitting box turner for your company’s needs, budget, and production, follow these steps:

Start by comparing the different box turning technologies on the market by reading "The Top 6 Box Turning Technologies: Which Should You Choose?"

Next, compare Impack's 5 main box turners side-by-side in the article "Comparing Impack Packaging's Box Turners: Which Is Best For Your Company?"

Finally, find out which box turner is right for your company by reading "What Box Turner is Right For You?"

👉 If you’re ready to choose a box turner for your company and need guidance, book an appointment with an Impack Expert and we’ll show you some of our box turners LIVE in action and answer any questions that are on your mind! PS: No commitment required.

👉 If you’ve got more questions, get in touch! We’ll be more than happy to answer all your questions!

If you’re thinking of adding a box turner to your gluing line, you’re probably asking yourself:

Are you searching for ways to improve your folder-gluer productivity and reach higher packing speeds?

If you’re looking to automate the turning of your boxes, you’re probably searching for a box turner.