Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?

2 min read

Stefan Badertscher

:

February 2, 2023

Stefan Badertscher

:

February 2, 2023

Are you currently looking to purchase a new folder-gluer packer or a folder-gluer stacker?

Depending on what kind of boxes you will produce, you may need to consider purchasing a box-turner.

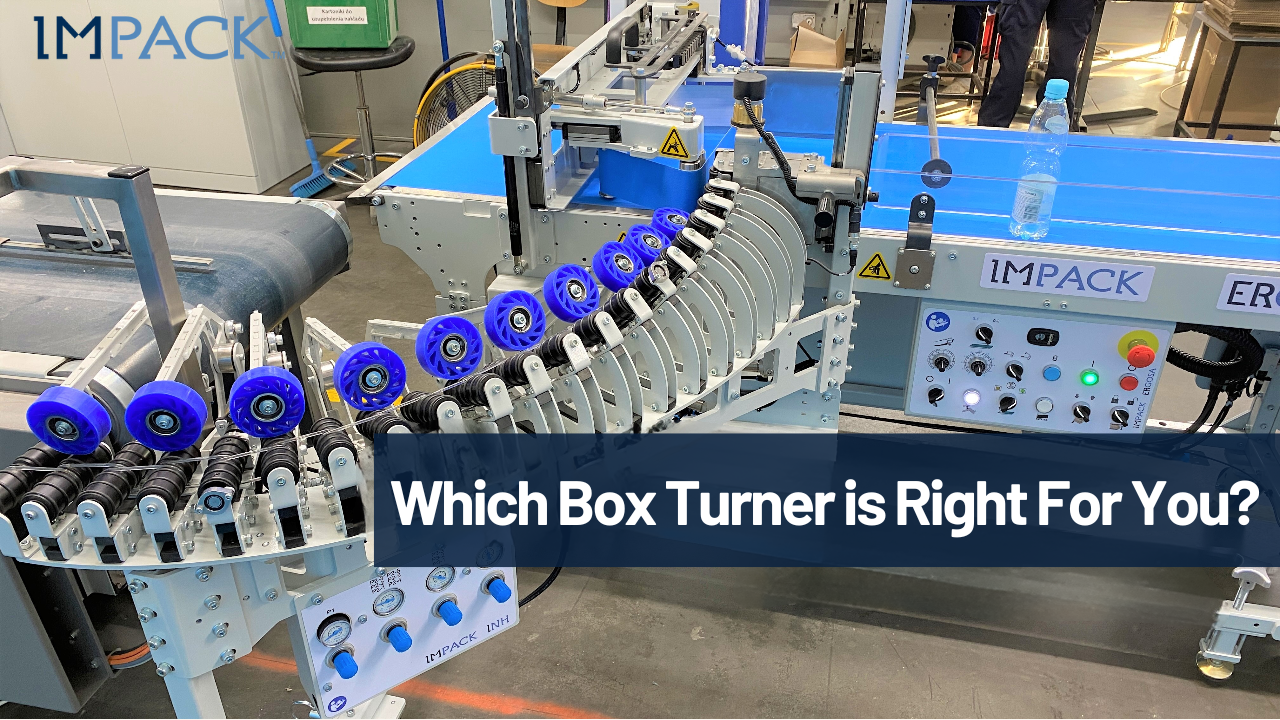

A box turner is a pre-packing device that individually turns each box in the shingle exiting the folder-gluer to form a new shingle with the boxes presented/oriented in the desired direction.

If you're looking to produce straight-line boxes, then you will automatically need a box-turner. Other types of boxes also necessitate box-turners to be produced, like 4-corner boxes and 6-corner boxes.

Here are the 6 box-turner options on the market, however in this article we will only cover Impack packaging's box-turners:

If you want a more detailed list of our box-turner options visit our box-turner page here!

The main question you’re now probably asking yourself is:

“How exactly do I go about choosing the best box-turner for my company?!”

This article will explain just that and help you choose the right box-turner for you!

If you have a packer or stacker after your folder-gluer, you most probably need a box-turner.

Straight-line boxes are almost always turned prior to them being packed into cases.

On the other straight-line boxes are almost never turned prior to being banded or strapped together.

Every packer or stacker requires a device to turn these boxes so as to facilitate the packing/stacking process. This device is what we call a box-turner. As to facilitate the packing process and fulfill the packing requirements.

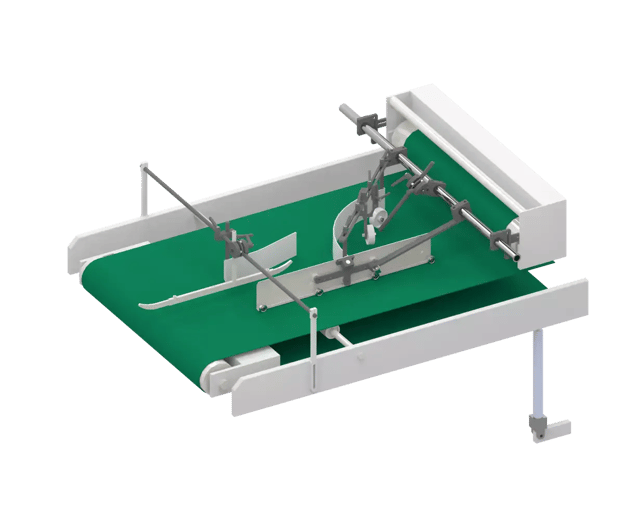

IN1 Box-Turner

If you are considering an Ergosa A packer, then your 2 available options are the IN2 and the INH box turners.

The IN2 and INH are integrated into Ergosa A’s conveyor to reduce cost and floor space.

If you are considering an Ergosa C packer, then your 4 available options are the IN2, IN3, IN1, and INH box turners.

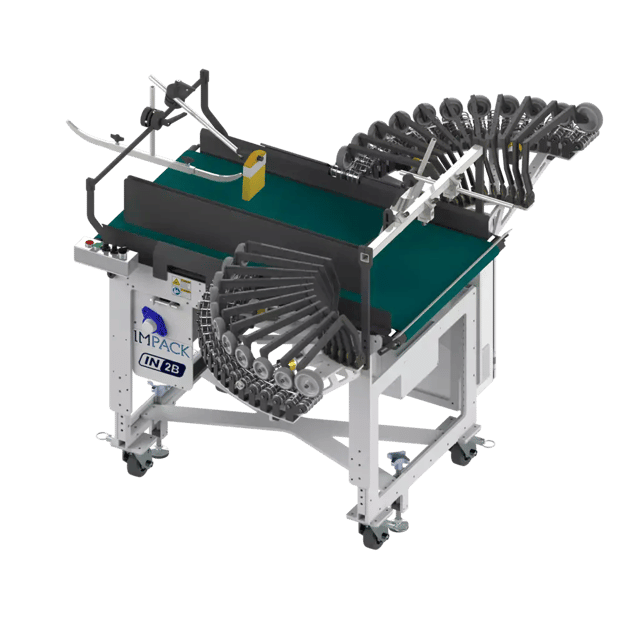

More importantly, almost every single Ergosa C packer is sold with an IN2.

If you are considering a Virtuo packer, then your 2 available options are the IN3 and IN2 box turners.

Usually, the best fit is the IN3 box turner. It has the ability to keep the centerline from turning to a straight-through setup, a very important feature on an automated or fully automated line.

IN2 Box-Turner

If you are considering an Everio stacker instead, then your 2 available options are the IN2 and the IN3 box turners.

If you already have a packer or stacker, not from Impack packaging that has case configuration limitations due to the packer’s lack of turning capabilities, then your 3 available options are the IN3, IN180, and the IN2 box turners.

If you want more in-depth information on your box-turner options or on folder-gluer packers, read the following articles:

![Ergosa Vs. Virtuo Vs. Everio: Which is the Best Folder-Gluer Packer? [+VIDEO]](https://impack.ca/hubfs/X21-011-1.png)

Are you in the market for a folder-gluer packer and looking for the perfect fit for your production?

If you’re looking to automate the turning of your boxes, you’re probably searching for a box turner.

![The 4 Most Common Folder-Gluer Packer Problems (+ Solutions) [+VIDEO]](https://impack.ca/hubfs/X21-005-1.png)

Are you thinking of getting a folder-gluer packer or automating the end of line process in your folding-gluing department?