Folder-Gluer Packaging Equipment

What Are Folder-Gluer Packaging Equipment?

Folder-gluer packaging equipment is an overarching term used to describe a wide range of packing solutions and peripherals that are added to a folder-gluer.

Packing solutions and peripherals are the automation and complementary solutions applied around a folder-gluer.

Those solutions fall into 4 main families 👇:

The image below shows you the organization of the 4 families of folder-gluer packaging equipment around a folder-gluer.

A graphical depiction of the flow of packaging equipment around a folder-gluer.

Each of those 4 families of packaging equipment includes distinct packing systems and peripherals with varying degrees, scopes, and levels of automation.

We classify those different levels of automation into 4 separate categories 👇:

- Manual packing

- Semi-Automated packing

- Automated packing

- and Fully-Automated packing.

Now that we’ve clearly defined the broad term “folder-gluer packaging equipment,” and what it encompasses, let’s explore each family individually and examine the solutions they have to offer!

🔍 Related: Looking for more information about the types of automation solutions available on the market? Find out the 4 different categories of folder-gluer packers and how they compare to one another.

The 4 Families of Folder-Gluer Packaging Equipment

What is a Pre-Feeder?

IMPACK’s Prefio: One of the only pre-feeders on the market for corrugated board.

A pre-feeder is a unit installed in front of a folder-gluer, and before the feeder, that continuously feeds the folder-gluer’s feeder.

💡 Purpose: pre-feeding equipment allow the folder-gluer’s feeder to run at a higher speed, with a perfect stack height, and without damaging the box blanks.

Who Needs a Pre-Feeder?

Packaging producers whose bottleneck has moved from the packing stage to the feeding stage after they’ve installed a folder-gluer packer.

What is a Pre-Packer?

IMPACK's MFA Batch Inverter and the IN3 Box Turner installed after the folder-gluer and before the packer (Both units are pre-packers).

A pre-packer is a unit installed right after the folder-gluer and before the packer. Very often, several pre-packer units are installed after the folder-gluer.

Those pre-packing equipment include box turners, batch inverters, and counting and separating devices.

💡 Purpose: Pre-packing equipment allow you to prepare the shingle of boxes so that they can be packed into the cases in the most efficient way possible.

Who Needs a Pre-Packer?

Anyone who has a folder-gluer packer, or is thinking of buying one, usually has the packer paired with a pre-packer.

The only exception is if you already have a pre-packer as part of your packer package.

For example, our Ergosa A packer already includes a box turner as part of the Ergosa A package.

The best choice of the box turner and the counting & separating device always depends on your box sizes, product mix and format restrictions. That is, they are entirely dependent on the type of folder-gluer packer or stacker you select.

A batch inverter is typically added to the packer unit when you are producing high volumes of crash-lock/auto-bottom boxes (~30-50 million per year or possibly less in some specific situations).

What is a Packer?

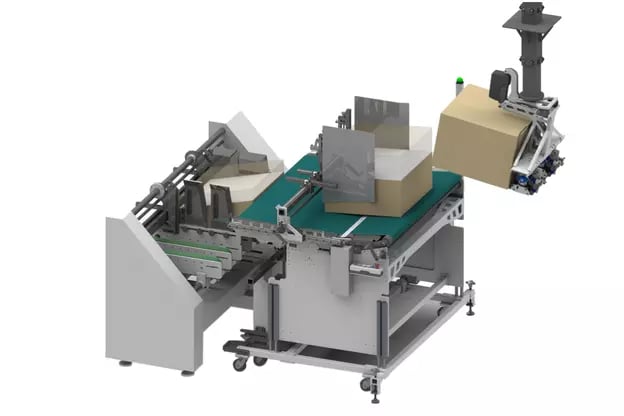

IMPACK’s Ergosa A: A semi-automatic packer with the performance of an automatic packer.

A packer is a unit installed behind, or at the end of a folder-gluer, and after the pre-packing equipment.

In other words, it is installed at the end of the flow of the packaging equipment as depicted in the image below.

A graphical depiction of the flow of packaging equipment around a folder-gluer.

💡 Purpose: A packer utilizes a modernized packing process that allows you to dramatically enhance the efficiency, ergonomy, and productivity of how you pack your boxes into cases (case packing process) by offering you automated case management capabilities.

Who Needs a Packer?

1. Packaging producers who are unable to push their folder-gluer’s productivity to its maximum potential because the packing person(s) cannot work that fast which thereby means that the packing process is the bottleneck of the production line.

Or

2. Packaging producers who want to achieve the same or higher productivity but with less people or without any human presence.

Or

3. Packaging producers who simply want to reduce the daily workload for their employees which could easily represent lifting 4-5 tons of cartons per day.

🔍 Related: What is a Folder-Gluer Packer and Who Needs One?

What is a Stacker?

IMPACK’S Everio: An automatic stacker for bundling all boxes coming from folder-gluers or rotary die cutters and sending them for the stacking/banding process.

Just like a packer, a stacker is a unit installed behind — or at the end of the folder-gluer — and after the pre-packing equipment.

Depending on the production processes, you either pack your boxes into cases (i.e. case packing) using a packer or stack your boxes to be banded/strapped together (i.e. box bundling) using a stacker.

In other words, you would either have a packer or a stacker after the pre-packing equipment, but some clients do both processes on the same folder-gluer.

💡 Purpose: A stacker utilizes a modernized bundling process that allows you to accumulate your boxes vertically and then send them for banding/strapping.

Who Needs a Stacker?

- Packaging producers who are unable to push their folder-gluer’s productivity to its maximum potential because the packing person(s) cannot work that fast, meaning that the bundling process is the bottleneck of the production line.

Or

- Packaging producers who have large production volumes and want to completely automate the bundling process.

Which Folder-Gluer Packaging Equipment is Best For You?

So, what folder-gluer packaging solution is best for you?

A pre-feeder, pre-packer, packer or a stacker?

It all boils down to what your needs are.

While there is no correct answer for all companies as each company’s needs are unique and different for every company, there are 7 important questions that you should be asking yourself:

✔️ Where is your bottleneck taking place?

-

- Is it at the gluing, packing, or feeding stage(s)?

✔️ What machines do you already have?

✔️ Are you exclusively doing case packing, exclusively doing banding/strapping, or both processes?

✔️ What types of boxes are you producing?

-

- Are you producing smaller boxes, medium-sized boxes, or larger boxes?

- Do you produce multi-row, multi-layer boxes or one-row, one-layer boxes?

- ✔️ Is uninterrupted, high-speed production your #1 priority?

- ✔️ What is your vision: Where do you want to go?

Need a More Detailed Explanation?

At IMPACK, we strongly believe that it is our responsibility to provide packaging producers with answers to their most pressing folder-gluer problems — even if we do not produce or sell folder-gluers.

"Why?"

Because our top goal here at IMPACK is one thing: Building trusting relationships.

And that means helping packaging producers make the most informed decision that is best for them.

Even if that means not choosing IMPACK.

So, we go out of our way to publish articles that answer the biggest frustrations packaging producers have about their folder-gluers.

Want to learn more about which packaging equipment is right for you and how to choose 🤔?

Your next steps would be to:

1. Compare Manual, Semi-Auto, Auto and Fully-Auto folder-gluer packers and find out which is best for your production.

2. Compare IMPACK’s 3 main folder-gluer packaging equipment in this side-by-side comparison: Ergosa Vs. Virtuo Vs. Everio - Which is the Best Folder-Gluer Packer?

3. Find out Which Folder-Gluer Packer is Right For You?