Increase Folder-Gluer Productivity

Is Buying a New Folder-Gluer the Solution to Your Problem?

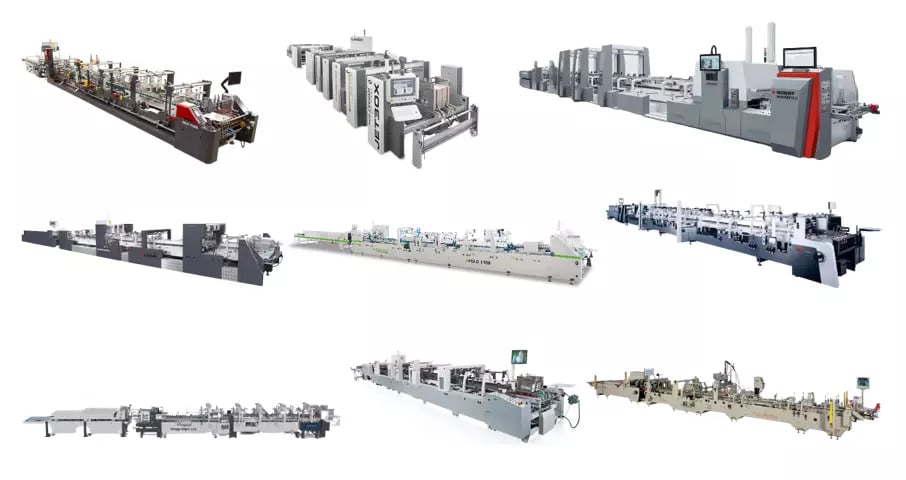

A graphical depiction of some of the most widely present folder-gluers on the market in alphabetical order (Ace Machinery, Bahmüller. Bobst, DGM, Eterna, Heidelberg-MK, KBA Duran, SBL, Vega).

Yes and no. A lot of packaging producers believe that buying a new folder-gluer is the solution to increase their productivity, and if you thought that too, you are not alone.

In some cases, buying a new folder-gluer is the best solution, and in other cases, it simply isn’t.

The first step to answering this question is to identify why the capacity of your current folder-gluer is limited.

-

In other words, where is the bottleneck taking place?

-

Is it at the gluing, packing or feeding stage(s)?

Once identified, the second step is to collect data on your production and work methods.

Analyzing this data will give you an accurate picture of where you are today, where you want to go, and how you will get there.

But more importantly, this data will be your stepping stone to deciding which solution is best for you.

Buying a New Folder-Gluer Could Be a Bad Decision

It is important for you to know that getting a new folder-gluer does not mean a simple hands-down investment in a gluer, period:

You need space which is a privilege in this industry.

You need another operator — another privilege.

You need to train those operators which is time-consuming.

You need other workers around the packing stations where job turnovers are very high.

You need equipment to manage the output/palletization — which can become expensive, and bulky, fairly quickly.

So, adding a new folder-gluer is not an overnight decision where you call your folder-gluer manufacturer and excitedly welcome the arrival of your new gluer to only then realize that you have limited space, unproductive operations or a wrong fit.

No one enjoys regretting a purchase, especially with high-ticket items that require a substantial investment from your hard earned money.

How to Increase Your Folder-Gluer Output & Boost Your Productivity

Investing in a new folder-gluer is not always the right decision to make.

There are other solutions that are sometimes the better choice to take.

What are those solutions?

- Learning how to increase your folder-gluer productivity without investing.

- Exploring folder-gluer packaging equipment and peripherals that require investing.

"What does this all mean?"

Let’s dive right into each of those solutions!

We completely understand that not everyone can or is ready to invest in packaging equipment.

And to be completely honest, investing in packaging equipment is not the best decision if you have not yet pushed your folder-gluer to its maximum potential.

But most companies won’t tell you that.

A shocker 😮? Yeah...it is quite a blunt statement, especially coming from folder-gluer packaging equipment manufacturers!

But our top goal here at IMPACK is one thing: Building trusting relationships.

And that means helping packaging producers like you make the most informed decision that is best for them.

Even if that means not choosing IMPACK.

And if you have not yet pushed your gluer to its maximum potential, then we would not recommend you to invest in our folder-gluer packaging equipment — even if you wanted to (It has happened before).

It is just not the smartest decision to take.

Instead, you should focus on mastering your folding-gluing process until you have a steady production outflow with a packing person(s) that can follow.

How can you do that? This brings us to the next point 👇!

Increase Your Folder-Gluer Productivity With $0 Investment

“I can actually increase the productivity of my gluer with zero investment?!”

I know...it sounds too good to be true. But, it is possible if understood and capitalized on wisely.

"How?"

There are a multitude of ways to boost your folder-gluer’s productivity without investing a dime 💰 👉 ❌.

And we've dedicated an entire article that lays out to you the top 5 tips to maximize your folder-gluer productivity (with $0 Investment).

But here is a short snapshot to get you thinking!

- Establish SOPs (Standard Operating Procedures) to document your internal processes.

- Have a logbook that details the setup of each machine for best practices.

- Analyze your work methods on each workstation.

- Assess walking patterns during setup and production.

- Organize the same types of boxes one after the another to reduce your setup time.

🔍 Learn more on how to implement these top 5 folder-gluer productivity maximization tips, and at what stage of your production process.

Sometimes You Have No Choice But to Invest in Packaging Equipment

IMPACK’S Ergosa A: A semi-automatic packer with the performance of an automatic packer. (Note: This specific Ergosa A was custom built as an XL size for one of our clients and is much larger than our standard Ergosa A’s).

“Hey, hey, hey! slow down; We are not following anymore!!”

Did you hear that?

That is the loud shouts of your packing personnel suddenly yelling because they cannot keep up with the speed.

At some point, you became good at tuning your folder-gluer through the implementation of the top 5 tips that involve $0 investment, and you ramped up your speed but the personnel just cannot keep up anymore.

So now, you have to deliberately slow down your folder-gluer and purposefully reduce your productivity.

After all, every process has its limitations and those limitations will eventually happen.

There will come a point where your folder-gluer will hit its maximum potential and there is nothing you can do to make the gluer run faster (or better) without investing in additional solutions.

Here's where folder-gluer packaging equipment come into play.

But “folder-gluer packaging equipment” is an overarching term for a wide range of packing solutions and peripherals around a folder-gluer.

And each of those solutions vary in scope, degree and levels of automation.

Taking it a step further, the integration of the right packaging solution depends on your product mix, type of production, box packing configuration, individual needs and a set of intertwined factors.

Hence, knowing that you need to invest in packaging equipment is not “the” ultimate answer to all your folder-gluer problems.

It is a great first step, but there’s a whole world to folder-gluer packaging equipment.

To make life much easier for you, we compiled the 7 fundamental tips to maximize your folder-gluer productivity with investing that is recommended by our top engineers and production specialists from their observations of over 1000 companies around the world.

Still looking for answers?

If you still can’t find what you’re looking for, or have questions that are specific to your company, contact us today! — IMPACK’s experts would love to help, and maybe even show you one of our machines LIVE in action 😉.

What’s your top concern?

👉 Do you want to increase your folder-gluer productivity?

👉 Are you interested in learning more about folder-gluer packaging equipment?