Automatischer Abpacker

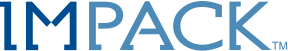

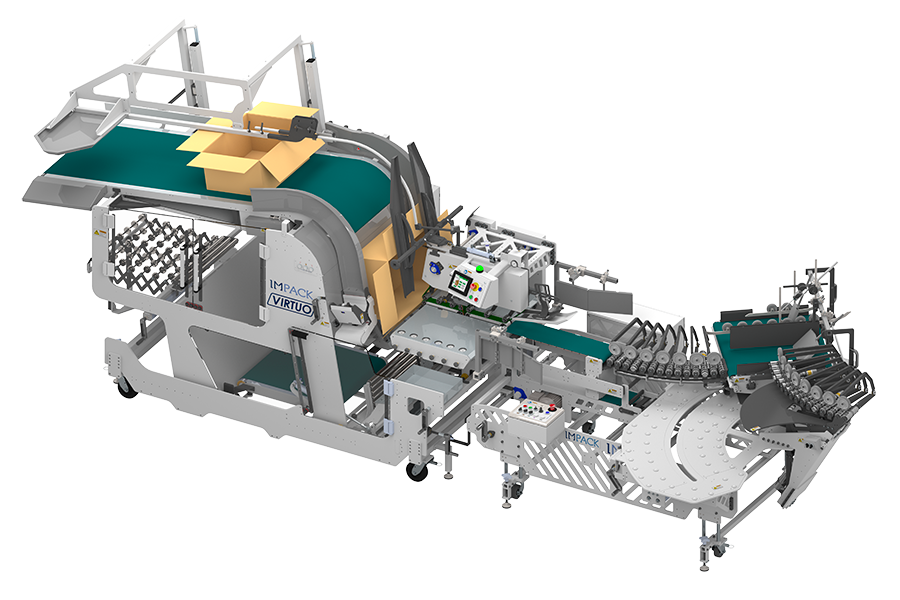

VIRTUO

Der Virtuo ist der modernste automatische Faltschachtel-Klebemaschinen Abpacker für Voll- und Wellpappe auf dem Markt.

Geschützt durch US-Patent Nr. 6594974 und Kanada-Patent Nr. 2401088

Er zeichnet sich durch seine Einfachheit und Vielseitigkeit aus und ist der kompakteste sowie wirtschaftlichste Abpacker auf dem Markt. Der Virtuo ist in mehreren Versionen erhältlich und verarbeitet verschiedene Formate (mittel bis sehr gross) und Arten von Schachteln (Längsnaht, 4/6 Punkte und Automatik-Boden), die in einer Reihe und einer Lage verpackt werden.

Für noch mehr Vielseitigkeit kann der automatische Faltschachtelklebepacker Virtuo mit verschiedenen IMPACK-Modulen kombiniert werden. Fügen Sie einen IN3 Schachtelwender hinzu, um eine hohe Flexibilität bei der Wahl der Ausrichtung der Schachteln in der Umkiste zu gewährleisten. Fügen Sie das MFA-Verschränkermodul für das automatische Abpacken von Vollpapp-Automatik-Bodenschachteln hinzu.

Automatischer Abpacker

Virtuo in Aktion.

Sehen Sie den Virtuo mit Schachtelwender IN3 und vollautomatischer Kistenzuführung in Aktion.

Virtuo Funktionen

- Der kompakteste automatische Schachtelabpacker auf dem Markt;

- Mittel- bis sehr grosse Formate;

- Längsnaht, 4/6 Punkte und Automatikboden;

- Kompatibel mit Voll und Wellpappe;

- Abpacken in einer Reihe und einer Lage;

- Geschwindigkeit: bis zu 8 Umkisten pro Minute;

- Kurze Rüstzeit;

- Hochpräziser Laserzähler;

- Umkisten Zuführer;

- Touchscreen-Schnittstelle.

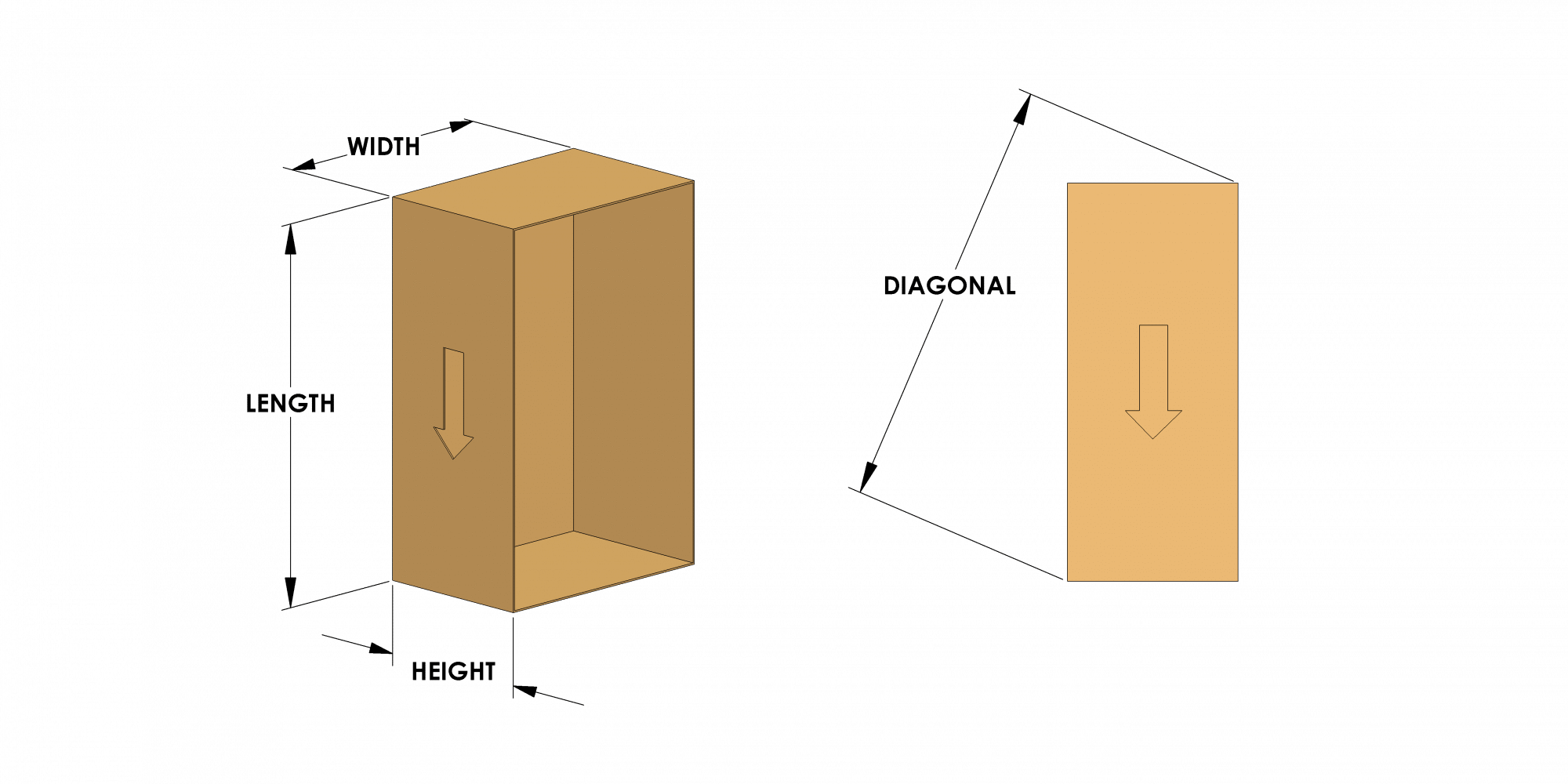

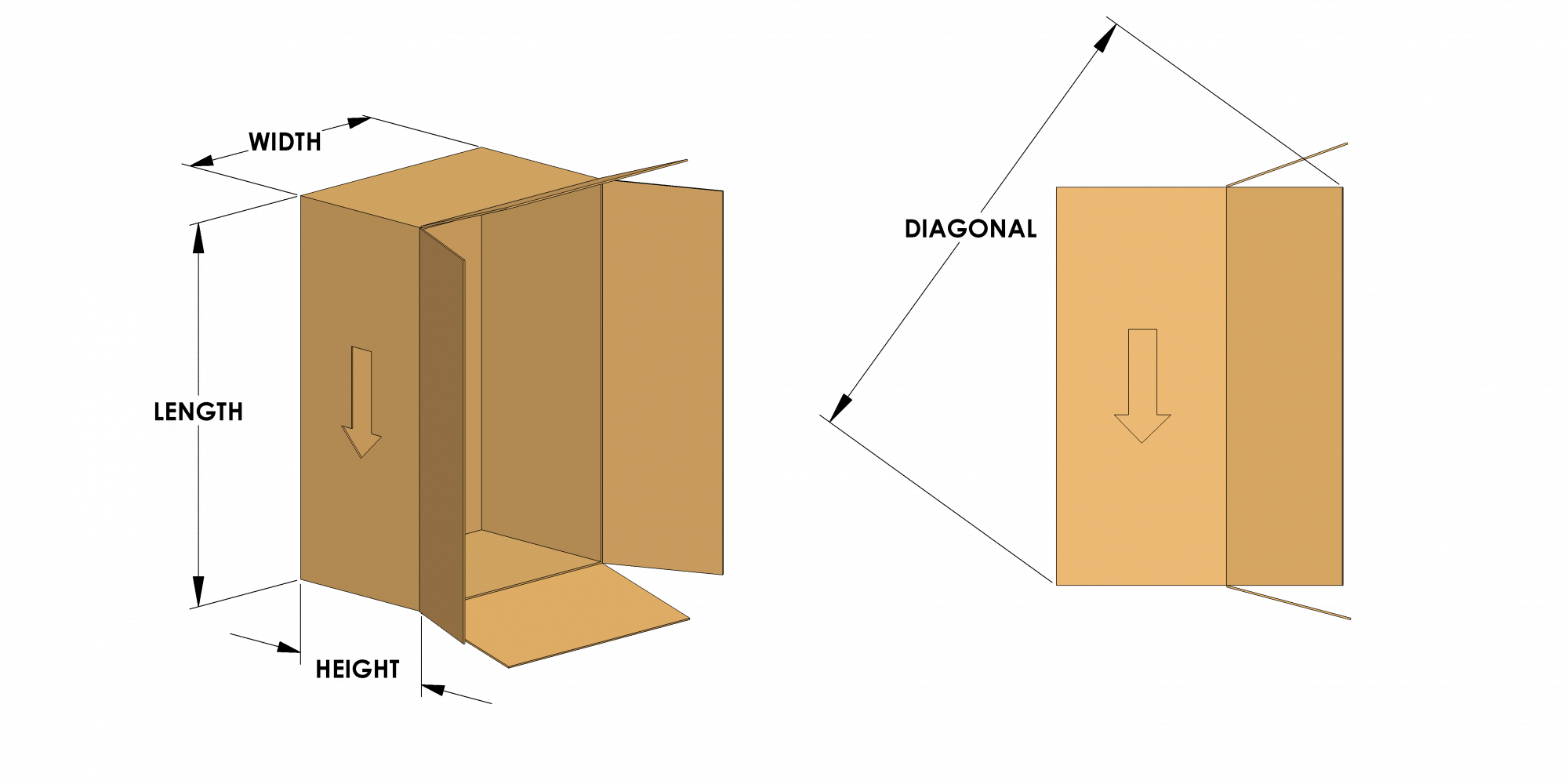

UMKISTEN MASSE - OHNE LASCHEN

UMKISTEN MASSE - MIT LASCHEN

Virtuo Dimensionen

95 in