What is the Ergosa C’s Vertical Mode and What Production is it Best Suited For [+ Video]?

Are you considering an Ergosa packer but feeling unsure about which packing mode(s) you need?

7 min read

Maxime Jacques

:

May 25, 2021

Maxime Jacques

:

May 25, 2021

👉 You’re thinking of purchasing an Ergosa packer to maximize your folder-gluer’s productivity, but you want to be 100% certain that you’re making the right choice.

The Ergosa is IMPACK’s semi-automatic folder-gluer packer and one of the only semi-automatic packers that exist, to date, on the market.

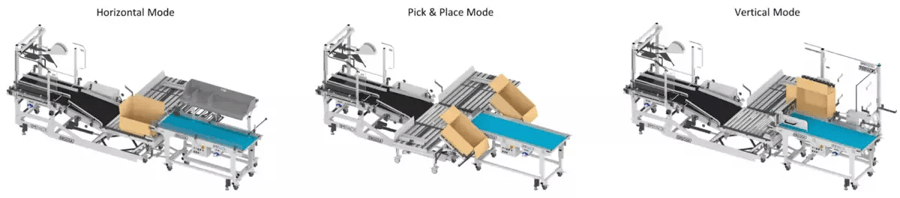

The Ergosa offers 3 main packing modes: The “Horizontal Mode,” the “Pick & Place (or Manual) Mode,” and the optional “Vertical Mode.”

The Horizontal Mode is the default packing mode of the Ergosa that is offered in both the Ergosa A and the Ergosa C.

“But, what is the Ergosa’s Horizontal Mode?”

“And how does it work?”

“Will it really make a massive change to my packing process?!”

This article + video answers those questions, and more, in under 9 minutes.

If you’re not familiar with what the Ergosa packer is or how it works, you may find our discussion quite technical. Therefore, I would strongly recommend you to check out our article “What is an Ergosa Packer & How Can It Improve My Packing Process?”

The Ergosa series includes 2 different versions: The Ergosa A and the Ergosa C.

The Ergosa A is the newer and more economical version of the two Ergosa packers. It is the go-to option for companies with tighter budgets and limited space availability.

The Ergosa C is the more advanced and versatile version of the Ergosa series that offers more configurations and multiple packing modes with several additional features and benefits.

🔍 Related: Ergosa A Vs. Ergosa C: Which Is Better For Your Production?

The Ergosa series offers 3 main packing modes: The “Horizontal Mode,” the “Pick & Place (or Manual) Mode,” and the “Vertical Mode.”

👉 The Ergosa A packer offers 2 of those 3 main packing modes:

👉 The Ergosa C packer offers the same 2 packing modes mentioned above + 1 additional optional packing mode:

🔍 Related: What are the Ergosa Packer’s 3 Main Packing Modes? (Definition, Features & Benefits)

The Ergosa’s Horizontal Mode is the standard packing mode of the Ergosa packer that is offered in both versions of the Ergosa series (the Ergosa A and the Ergosa C).

It features an ergonomic design with a new original packing methodology for handling small to medium-sized straight line boxes and small 4/6 corners.

Instead of hand-packing your boxes in small batches that are limited by as much as your packing person(s) hands can carry per movement, the Ergosa’s Horizontal Mode allows you to pack a complete row of boxes — in one single motion — by sliding the boxes into the case.

No lifting of loads is required.

This “sliding movement” capability is depicted in the image below:

This same “sliding movement” is also responsible for a reduction in the number of packing persons needed at the packing station (often from 2 packing persons to 1 packing person) and an increase in packing speed.

Because you can now pack a full row of boxes in one motion, instead of by limited small batches as you would normally do in the traditional manual packing process, the number of boxes per movement increases significantly which results in a much higher packing speed.

For example, if you are hand-packing straight line boxes with the most common manual packing help/aid, a Collecting Table, you would typically need 2 packing persons that would run at the speed of about 25,000-30,000 boxes per hour.

Now, if you pack those straight line boxes with the Ergosa packer in Horizontal Mode, you will be able to achieve a speed of 50,000-60,000 boxes per hour, or more, and with only 1 packing person (instead of 2 packing persons).

Thus, you would typically see twice the packing speed per packing person for straight lines with the Horizontal Mode (if the case packing configuration allows it).

The Ergosa’s Horizontal Mode greatly enhances the efficiency, ergonomy, and speed of your production with packing speeds that may exceed 100,000 boxes per hour.

🔍 Related: What's the Difference between Collecting Tables and the Ergosa Packer?

There is no major difference between the Ergosa A and Ergosa C’s Horizontal Modes. The Ergosa A and Ergosa C’s Horizontal Modes are exactly the same and the case packing process does not change. But the Ergosa A packer can have slightly lower maximum speeds (10% to 20%) than the Ergosa C packer.

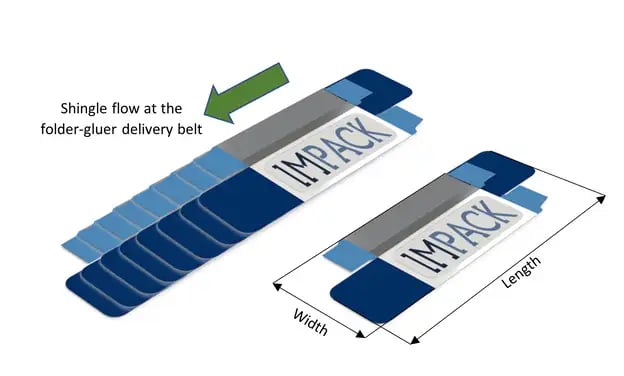

👉 Step #1: Place the empty case on the case holder system located at the end of the accumulation conveyor where the box shingle arrives from the folder-gluer as shown in the schematic diagram below.

.webp?width=624&name=pasted%20image%200%20(1).webp)

The case holder system displayed below is adjustable in height such that the case opening is a few millimeters below the top of the accumulation conveyor. This allows the operator to slide the row into the case without any disturbance.

In addition, the case holder system allows you to keep the case always in place while packing rows into cases. The lateral clamping system prevents the case from moving during the sliding movement.

.webp?width=424&name=ezgif.com-gif-maker%20(85).webp)

👉 Step #2: Separate a full row of boxes from the box shingle and bring this row close to the end of the accumulation conveyor like the operator does in the image below.

.webp?width=624&name=ezgif.com-gif-maker%20(87).webp)

👉 Step #3: In one single movement, slide the full row of boxes into the case.

.webp?width=624&name=ezgif.com-gif-maker%20(89).webp)

If you need to pack multiple rows, repeat step #2 and step #3.

👉 Step #4: Once the row(s) of boxes has been packed into the case, simply press the ejection button and the Ergosa (A or C) will release the case from the case holder system.

Thanks to the Ergosa’s automated case management system, the lifting conveyor will bring the case to a standard height and once ejected, the case goes to palletization.

.webp?width=624&name=ezgif.com-gif-maker%20(91).webp)

.webp?width=624&name=ezgif.com-gif-maker%20(93).webp)

.webp?width=624&name=ezgif.com-gif-maker%20(95).webp)

.webp?width=624&name=ezgif.com-gif-maker%20(97).webp)

The Horizontal Mode is mainly intended for 2 types of boxes: Straight line boxes and 4/6 corner boxes.

.webp?width=424&name=3-Seal-end%20(1).webp)

Straight lines are the box of choice for the Horizontal Mode.

In fact, the Horizontal Mode was designed primarily for straight line boxes. The working principles of the Horizontal Mode allow you to dramatically reduce the manual workload required by your operators, enhance the ergonomy of your workstations, and substantially boost your packing speed. The goal is to reduce the number of actions/movements that your operator is required to perform.

Therefore, in most cases, the Horizontal Mode requires a box turner to prepare the orientation of the boxes so that they automatically rest on their folded edge without requiring the packing person(s) to perform this operation.

This, thereby, facilitates better handling of the boxes by the packing personnel, reduces the cycle time, and ultimately increases your folder-gluer’s productivity.

.webp?width=624&name=ezgif.com-gif-maker%20(48).webp)

Although the Vertical Mode is the preferred method for 4/6 corner boxes, the Horizontal Mode can also run 4/6 corners.

As a general rule of thumb, the Horizontal Mode is capable of offering equivalent performances to the Vertical Mode if you’re running small 4/6 corners.

As far as the packing configuration is concerned, the Ergosa’s Horizontal Mode offers absolute flexibility. The Horizontal Mode allows multi-row, multi-layer packing without any limitations/restrictions to the number of rows and layers you’re packing.

So whether your packing configuration is 1 row-1 layer packing, 1 row-2 layers packing, or 4 rows-4 layers packing, the Horizontal Mode is capable of adapting. The only limitation that exists is that your boxes and cases should meet the specifications defined by the Ergosa packer.

.webp?width=624&name=pasted%20image%200%20(8).webp)

Here is the answer in less than 60 seconds ⏱️:

🡲 Here, the Vertical Mode is the most fitting option.

🡲 Here, the Vertical Mode or the Pick & Place Mode is the most fitting option.

🡲 Here, you should consider the Everio stacker instead of the Ergosa packer as the Ergosa is mainly designed for case packing and not box bundling.

🡲 Here, the Pick & Place Mode is the most fitting option.

Choosing the right packing mode(s) for your production is fundamental to ensuring that you achieve top packing speeds, reduce bottlenecks, and unleash your folder-gluer’s full potential.

The Horizontal Mode is just one of the Ergosa’s 3 main packing modes. The Ergosa also offers the Pick & Place (or Manual) Mode and the optional Vertical Mode, as well as several other add-on packing modes.

For more in-depth information on each packing mode offered by the Ergosa packer, check out the following links:

What are the Ergosa Packer’s 3 Main Packing Modes? — An Overview.

What is the Ergosa C’s optional Vertical Mode and What Production is It Best Suited For?

What is the Ergosa’s Pick & Place Mode and What Production is It Best Suited For?

Got questions that are specific to your company? We’re happy to help! Contact an IMPACK expert today and we’ll show you the Ergosa, and its 3 different packing modes, in action 😉.

![What is the Ergosa C’s Vertical Mode and What Production is it Best Suited For [+ Video]?](https://impack.ca/hubfs/X21-021.png)

Are you considering an Ergosa packer but feeling unsure about which packing mode(s) you need?

If you’re considering the purchase of an Ergosa packer, you’re probably wondering: What benefits can the Ergosa provide to my packing process?

![Impack Packaging Ergosa Packer’s 3 Packing Modes | Complete Overview [+VIDEO]](https://impack.ca/hubfs/X21-026-2.png)

Are you looking to install a folder-gluer packer on your folder-gluer but want something that won’t make your company go broke?