Collecting Tables Vs. Ergosa Packer: Comparison & Evaluation

Let’s address the elephant in the room that most packaging producers avoid talking about 👇:

13 min read

Stefan Badertscher

:

May 13, 2021

Stefan Badertscher

:

May 13, 2021

![Ergosa A Vs. Ergosa C: Which Is Better For Your Production? [+ VIDEO]](https://impack.ca/hubfs/X21-020.png)

👉 You’re considering an Ergosa to boost your folder-gluer’s productivity, but you’re not sure which Ergosa packer is best for you.

“What’s the difference between the Ergosa A packer and the Ergosa C packer?”

“But more importantly, which is better for your specific production?”

Every company is different and the answers to those 2 questions can vary from company to company, industry to industry, and production to production.

We, at IMPACK, manufacture and install the Ergosa packer, as well as, other manual, automatic, and fully automatic folder-gluer packers. And we get asked those questions on a daily basis.

In this VIDEO + ARTICLE, expect to learn about 👇:

And I promise, I will keep this article as direct and straightforward as possible!

Let’s dive in, shall we?

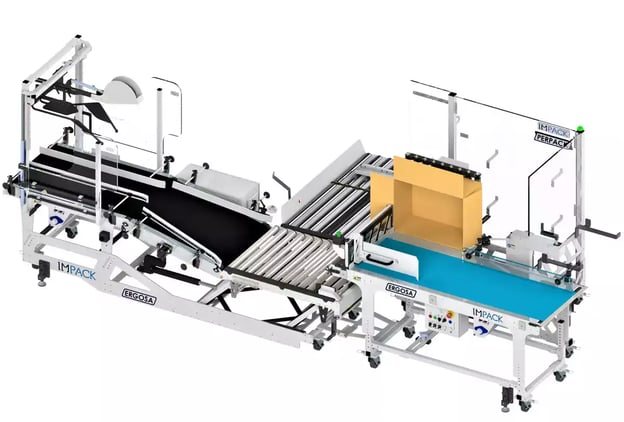

The Ergosa is a semi-automatic folder-gluer packer that optimizes the ergonomy and efficiency of your case packing process and helps you maximize your folder-gluer’s productivity.

💡 Quick Fact: The name “Ergosa” comes from the abbreviation of Ergo-nomic, semi-automatic.

As the name suggests, the Ergosa packer is an ergonomic and semi-automatic folder-gluer packer.

The Ergosa is, to date, one of the only semi-automatic packers that exist on the market, and its original packing methodology offers a higher level of ergonomy than most packers and Collecting Tables on the market.

Different folder-gluer packer manufacturers offer distinct solutions with varying levels of automation. Those different levels of automation can be broken down into 4 categories: Manual packing, Semi-Automated packing, Automated packing, and Fully-Automated packing.

The Ergosa packer falls into the semi-automated packing category. A semi-automatic packer includes at least one automated functionality. This means that the operator of a semi-automatic packer remains the key factor of the packing process, but with the help of at least one automated function.

As for the Ergosa, this auto function is the case management system. That is, the Ergosa is semi-automatic because it includes an automated case management process.

If you want to dig deeper into the 4 levels of automation that different folder-gluer packers can offer, read our article “What’s the difference between Manual, Semi-Auto, Auto and Fully-Auto Folder-Gluer Packers.” It talks about the 4 levels of automation in detail!

Okay. By now you probably already have a good idea of what the Ergosa packer is. So, let’s dive into what you landed on this article for: The two types of the Ergosa series.

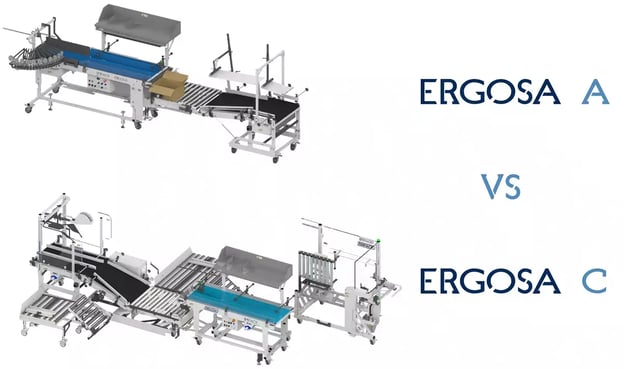

The Ergosa series consists of 2 different types of the Ergosa: The Ergosa A and the Ergosa C.

Dating back to 2003, the Ergosa C was the first-ever Ergosa packer that we built here at IMPACK. As of 2021, we have built and sold over 120 units of the Ergosa C.

The Ergosa A is the newer and younger version of the two Ergosa packers (about 3 years old). It started as an internal cost-savings project for a few clients (a custom machine) and then evolved into a fully-fledged version of the Ergosa series after we received several requests for a less costly packer, particularly from the Asian market.

And we answered with not only a much cheaper machine, but also a more versatile packer that is highly configurable and adaptable for any production, box style, or industry.

Because the Ergosa packer can easily run any box you shoot through your folder-gluer, we credit it for being a universal packer.

The “Ergosa A” is a simple, economical, and compact semi-automatic packer that offers a big improvement in ergonomics and packing speed.

Simple in that it is designed so that anyone who knows how to operate a folder-gluer can quickly learn how to operate, and maintain, the Ergosa packer.

Economical in that it is the less costly packer of the Ergosa series and is much more cost-effective than most automatic and fully-automatic folder-gluer packers on the market. All that while being highly configurable and adaptable to any type of production or box style.

Compact in that it adapts to any restricted space and serves as the ideal solution for companies with limited space availability.

In short, the Ergosa A packer is the go-to option for companies with tighter budgets and limited space availability.

The Ergosa A includes an integrated IN2 box turner and offers 2 packing modes: The “Horizontal Mode” and the “Pick & Place (or Manual) Mode.”

Its ergonomic design and new original packing methodology allows a full row of boxes to be slid into the case, in one single motion, without being lifted, hence reducing manual workload and the risk of repetitive strain injuries (RSI).

It is compatible with folding cartons and corrugated boards and handles various small to medium-sized boxes including straight-lines, 4-corners, and 6-corners with multi-row, multi-layer packing capabilities. That said, processing 4-corners and 6-corners is only fast and ergonomic when run on the Ergosa C in Vertical Mode.

The Ergosa A is also capable of processing crash-lock/auto-bottom boxes but not as fast or as ergonomic as if you were to run them on the Ergosa C with an MFA Batch Inverting Module. More on this point shortly!

The “Ergosa C” is a high-performance and versatile packer with the perfect combination between a semi-automatic packer and an automatic packer.

Of all our folder-gluer packers, the Ergosa C’s versatility and modularity make it IMPACK’s most sold packer over the last few decades.

In other words, the Ergosa C is the more advanced and versatile version of the Ergosa series that offers more configurations and multiple packing modes with several additional features and benefits that the Ergosa A does not offer.

The Ergosa C is compatible with folding carton and corrugated board boxes and includes all the features and benefits that an Ergosa A offers plus 5 additional features:

➕It offers one additional packing mode (Making a total of 3 main packing modes: Horizontal Mode, Pick & Place/Manual Mode, and an optional Vertical Mode).

➕ It packs 4-corners and 6-corners faster and more ergonomically than an Ergosa A.

➕ It packs crash-lock/auto-bottom boxes faster and more ergonomically than an Ergosa A when combined with the MFA Batch Inverting Module.

➕ It offers the possibility to pack big format boxes.

There are 4 key differences between the Ergosa A and the Ergosa C that are important to consider:

The Ergosa A includes an integrated box turner whereas the Ergosa C does not.

The Ergosa A packer includes an integrated box turner (the IN2 or INH box turner) as part of the Ergosa package. Almost every single Ergosa A is sold with an IN2 box turner.

The INH is our newly developed turner as of 2020. It is the most efficient and the best fit for the Ergosa A packer but it is not as versatile as the IN2 just yet. In cases where the INH won’t fit, the IN2 is also an excellent second choice.

The Ergosa C packer, on the other hand, does not include a box turner. Instead, you need to purchase an additional extra box turning module for the Ergosa C.

Most Ergosa C packers are sold with an additional IN2 box turner as it is the most cost-effective module for box turning. The INH is the latest model and will be more widely available and readily chosen from 2021 onwards.

The Ergosa A includes only 2 packing modes and is limited to those 2 modes whereas the Ergosa C includes 3 main packing modes and many additional optional modes.

.webp?width=624&name=ezgif.com-gif-maker%20(46).webp)

Another major difference between the Ergosa A and the Ergosa C is the number of packing modes offered.

The standard Ergosa A package includes only 2 packing modes:

The Horizontal Mode and the Pick & Place (or Manual) Mode. The Pick & Place Mode includes one manual packing station for one packing person.

In contrast, the standard Ergosa C package has 3 main packing modes: The Horizontal Mode, an optional Vertical Mode, and the Pick & Place (or Manual) Mode. The Pick & Place Mode includes two manual packing stations for two packing persons. Those 2 manual packing stations are called the MAE Modules. Hence, the Pick & Place Mode of the Ergosa C is more ergonomic and productive than the Ergosa A.

1. When we say that the Ergosa C packer includes “3 main packing modes,” we say “main,” because the standard Ergosa C package includes those 3 packing modes, but those are not the only modes that the Ergosa C can offer.

More specifically, other optional add-on modes can be added to the Ergosa C, besides those 3 main packing modes. For example, the “Tray Holder Mode” for very small boxes or adjusted versions of the vertical mode that are adapted to work with banding/strapping machines. In direct contrast, the Ergosa A is limited to 2 packing modes only.

2. Although the Vertical Mode is included in most Ergosa C packages, it is an option and not a requirement. It can either be included as part of the Ergosa C package or be retrofitted (if needed) at any time in the future and is as simple as “plug and play" (if you have the connections prepared in advance).

3. Those specifications we discussed are of the standard Ergosa A and C packers. By “standard,” we mean the standard packages that we offer of the Ergosa packers. That said, custom solutions are not foreign to IMPACK. We can customize and configure our machines according to your production realities and constraints 😉.

If you’re interested to learn more about how each packing mode works, our article “What Are the Ergosa Packer’s Main Packing Modes & What Benefits Do They Offer?" dives into how each packing mode works and which mode is best for what production.

But — here is a quick overview to get you thinking!

The “Horizontal Mode” allows you to pack a full row of boxes, in one single motion, by sliding the full row of boxes into the case. No lifting of loads is required.

Ideal for small to medium-sized boxes, straight-lines, and offers multi-row, multi-layer packing capabilities.

The “Vertical Mode” allows you to pack a full row of boxes, in one single motion, by pushing the full row of boxes into the case using the PerPack Module.

Ideal for Medium to large-sized boxes, large and heavy straight-lines, 4/6 corners, and crash-lock/auto-bottom boxes (if you pair it with an MFA Batch Inverting Module). Offers 1 or 2 row(s) and 1 layer packing capabilities (2 layers is also possible under certain conditions).

The “Pick & Place (or Manual) Mode” offers you great flexibility by giving you the capability to run any box you shoot through your folder-gluer.

Ideal for when the Horizontal and Vertical Modes do not suit a specific box production.

The Ergosa A has fewer packing modes, fewer features, and is less customizable relative to the Ergosa C, but it is less costly and better suited for tighter spaces.

A final important point to consider is that the Vertical Mode is exclusive to the Ergosa C and cannot be added, or retrofitted, at a later time, to the Ergosa A.

To help you make a more educated decision on which Ergosa packer is better for your company, we created the table below that compares the specifications of the Ergosa A Vs. the Ergosa C.

|

Feature |

Ergosa C with add-on IN2 Box Turner |

Ergosa A with included IN2 Box Turner |

|

Horizontal Mode: Box compatibility |

|

|

|

Horizontal Mode: Packing speed capacity |

|

|

|

Vertical Mode: Box compatibility |

|

|

|

Vertical Mode: Packing speed capacity |

|

|

|

Pick & Place Mode: Box compatibility |

|

|

|

Any future upgrades possible? |

Yes:

|

|

|

What IMPACK modules can be integrated? |

|

|

|

Packing side of the operation |

|

|

|

Box turning capabilities |

|

|

|

Case conveyor customization |

|

|

|

Shingle pitch control (distance between the boxes on the accumulation conveyor) |

|

|

|

Typical machine length |

Depends on the configuration:

|

|

|

Change over time |

|

|

|

Possible case configuration |

|

|

|

Other differences |

|

|

|

|

|

|

|

|

|

|

|

|

Price range ($ CAD) |

|

|

|

What additional add-ons are available? |

|

|

The Ergosa A packer is a better choice for you if your folder-gluer is mainly producing straight-lines and you have a tight budget and(or) limited space available but want to dramatically increase the ergonomy, efficiency, and productivity of your case packing process.

The Ergosa C packer is a better choice for you if your folder-gluer is mainly producing a large proportion of crash-lock/auto-bottom boxes or big formats and(or) you want to increase your packing speed per packing person for various box types i.e. straight-lines, 4-corners, 6-corners, and crash-lock/auto-bottom boxes.

That said, both Ergosa packers are universal packers in the sense that although the Ergosa C in Vertical Mode is more specialized for 4/6 corners, crash-lock/auto-bottom boxes (when paired with an MFA Batch Inverting Module) and big formats, the Ergosa A can still run those complex boxes in Pick & Place (or Manual) Mode but of course, it won’t be as fast or as ergonomic as with an Ergosa C.

And as you already know by now, the Ergosa A does not offer a Vertical Mode and hence you cannot integrate the MFA Batch Inverting Module to the Ergosa A.

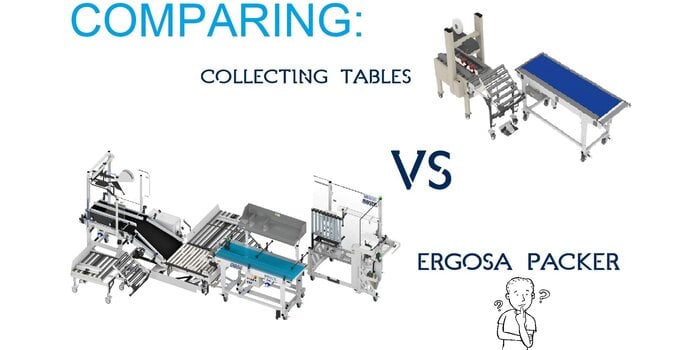

None of the Ergosa packers (A or C) are good fits if:

1. You have small production runs of various, different box formats (5,000-10,000 boxes).

In this specific situation, a Collecting Table like IMPACK’s “Packing Help Station” or the other Collecting Tables on the market would be a much better choice. Some examples of the most popular Collecting Tables in western countries are Bobst’s Handypack GT, KBA Duran's Omega Pack Station and Tünkers' FAS 480.

🔍 Related: What's the Difference between Collecting Tables and the Ergosa Packer?

2. You produce a large number of straight-line boxes with the same format per production run (several hundreds of thousands to millions) and your goal is to achieve the highest running speed available on the market.

In this case, an automatic packer like our Virtuo packer would be a better option if your production is one-row, one-layer packing.

However, if your typical production is multi-row, multi-layer packing, IMPACK’s Virtuo is not the right fit for you. Instead, Bobst’s Carton Pack 4, Heidelberg’s Diana Packer, Koenig & Bauer Duran Machinery’s Omega Pack Station or Ace Machinery’s Sig-Pack would be a better fit. Those are just some examples of the most common multi-row, multi-layer automatic packers on the market.

3. You are exclusively doing banding/strapping. In this case, you would need a folder-gluer stacker instead of a packer such as IMPACK’s Everio stacker, or the many other stackers on the market. Some of the most widely present stackers are Vega Group’s Easypack, Bahmueller’s PowerPacker or Consultec’s COLT 1000 / II.

Now if you are alternating between case packing and banding/strapping on the same folder-gluer, then the Ergosa packer could be a perfect fit.

This is because we recently developed a module on the Ergosa inspired by our PerPack Module that allows you to push batches of boxes into a banding/strapping machine so that they can be bundled together.

So, the Ergosa could pack the boxes into cases as a packer would do, as well as, be adapted to act as a stacker to stack boxes that are to be banded/strapped together.

Otherwise, a custom project could be considered (especially if you have a large production).

Do you have your heart set on which Ergosa packer is best for you?

Or maybe you have more questions specific to your company that you want answers for?

We’re here to help!

📞 Give us a call today! and we’ll show you the Ergosa Packers LIVE in action 😉!

UP NEXT:

What is an Ergosa & How Can It Improve My Packing Process?

What Are the Ergosa Packer’s Main Packing Modes & What Benefits Do They Offer?

Let’s address the elephant in the room that most packaging producers avoid talking about 👇:

With the growing complexity of the cardboard packaging market, the demand for custom-tailored boxes is increasing at a monstrous rate.

![Impack Packaging Ergosa Packer’s 3 Packing Modes | Complete Overview [+VIDEO]](https://impack.ca/hubfs/X21-026-2.png)

Are you looking to install a folder-gluer packer on your folder-gluer but want something that won’t make your company go broke?